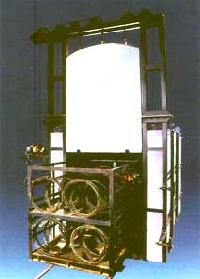

Vacuum Heat Treatment Furnace

Get Price Quote

Vacuum heat treatment prevents distortion of the material and provides an oxidation free surface. HHV’s cold - walled horizontal vacuum heat treatment furnace has oil and gas quenching capability. The furnace has a horizontally mounted double walled water cooled chamber fabricated with carbon steel in accordance with ASME code. It has a diameter of 1100 mm, wall thickness of 12mm and a cylindrical length of 1000mm housing the hot zone of size of 730mm (D) x 750mm Depth. A fork lift facility has been provided for loading and unloading of charge of up to 200 kg in weight.

Heat Treatment Furnaces

Get Price Quote

We are offering heat treatment furnaces. the wide range of heat treatment furnaces manufactured and supplied by us are applied in fields like annealing, forging, hardening, preheating, quenching, homogenizing, carburizing, carbonitriding, stress relief, tempering, pelletizing etc. Heat sources offered by us in these machines are fuel based and electric heating elements. Max temp:1600'c

Best Deals from Heat Treatment Furnaces

Vacuum Heat Treatment Furnace

200,000 Per Piece

Heat Treatment Furnaces

Get Price Quote

Silcarb manufactures various type of Heat Treatment Furnaces for the ferrous and the non-ferrous industry. Silcarb has emerged as the most reliable name for Heat Treatment Furnaces in India. For the past three decades, it is engaged in manufacturing and supplying of Heat Treatment Furnaces located in Bangalore, South India. Being an ISO 9001: 2008 certified company, we never compromise on quality and have set highest standards to maintain optimum product quality. The product we are offering is widely known for its energy efficiency and enhanced serviceability.

Vacuum Heat Treatment Furnace

Get Price Quote

It is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the re-crystallization temperature and maintaining a suitable temperature, and then cooling. Annealing is used to induce ductility, soften material, relieve internal stresses, refine the structure by making it homogeneous, and improve cold working properties. Machining induces stresses in parts. The bigger and more complex the part, the more the stresses. These stresses can cause distortions in the part long term. If the parts are clamped in service, then cracking could occur. Also hole locations can change causing them to go out of tolerance. For these reasons, stress relieving is often necessary. Tempering is a process done subsequent to quench hardening. Quench-hardened parts are often too brittle. This brittleness is caused by a predominance of Martensite. This brittleness is removed by tempering. Tempering results in a desired combination of hardness, ductility, toughness, strength, and structural stability. Tempering is done immediately after quench hardening. When the steel cools to about 40 ºC (104 ºF) after quenching, it is ready to be tempered. The part is reheated to a temperature of 150 to 400 ºC (302 to 752 ºF).

Heat Treatment Pit Type Furnace

Get Price Quote

Therelek Engineers manufactures Pit Carburizing Furnace for hardening and carburizing. Designed upto 1000°C with high nickel and chrome based retorts and circulation fans, these furnaces are rugged and efficient. Feature Longer Life Fine Surface Finish Low Maintenance Anti-Galling Properties Anti-Corrosive

Vacuum Heat Treatment Furnace

Get Price Quote

Vacuum Theat treatment furnace manufacturers in India. Since its inception, Triad has been delivering high quality thermal processing equipment for customers. At Triad Engineers, we believe that innovative products and constant improvisation of the existing products. We do this by adding new features and pave a straight path for success and growth. Triad achieves this by partnering with other world leading heat treatment equipment providers.

heat treatment furnace

Get Price Quote

Providing you the best range of pit furnace, annealing furnace, bogie hearth wire annealing furnace, bell furnace, belt conveyor furnace and industrial chemical dryer with effective & timely delivery.

Vacuum Heat Treatment Furnace

Get Price Quote

LVH has world class vacuum furnaces of "versa treat" brand with latest technology from its own group LVT. Mainly concentrating to ensure consistent metallurgical results as per standards which in turn results in multi fold life of heat treated products. LVH production centres are spread across the country in order to serve the customers at their door step. LVH has well designed systems & components as in very good pumping stations, optimized heat exchangers including the quintessential quenching fan and the optimized heating chambers.

Aluminium Heat Treating and Melting Furnaces

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. Range Solutionising (precipitation) with rapid water quench facility as per Aerospace requirment. Ageing Gas/ LDO/ electrically heated, Melting and holding furnaces (including tower melting).

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces on quality and have set highest standards to maintain optimum product quality. The product we are offering is widely known for its energy efficiency and enhanced serviceability.

industrial heat treatment furnaces

Get Price Quote

industrial heat treatment furnaces

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces, high temperature sintering furnaces

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces, sealed quench furnaces, integral quench furnace

heat treatments

Get Price Quote

heat treatments, forging forged products, forged equipment

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces

Heat Treatment Furnaces

Get Price Quote

Heat Treatment Furnaces, ceramic kilns, Ovens, combustion equipment