Medium Frequency Induction Melting Furnace

75,000 Per Piece

375000 Set(s) (MOQ)

Vacuum Induction Melting Casting Furnace

Get Price Quote

HHVs Vacuum Induction Melting (VIM) has a reliable process and very versatile.It can be used for producing a wide range of materials, including special alloys that are cast for high value critical parts such as golf club heads, aerospace parts, automotive parts, and other equipment components that need special mechanical properties for successful operations.

Best Deals from Induction Furnace

Induction Melting Furnace

Get Price Quote

Features : Efficient IGBT based Induction Furnace Portable module Soft switching technology for power saving Robust Industrial design for high and low volume melting Steel frame construction and Auto shut feature on fault condition Applications : Jewellery application such as melting of precious metals like gold, silver, copper etc. Melting of various alloys for laboratory purposes Heat treatment of metal parts and research applications. Purification of Silicon Nb: " industrial melting furnaces are available with power rating from 10kw to 1000 for foundry casting etc."

Induction Melting Furnace

300,000 Per Piece

Electric Induction Furnace

Get Price Quote

Induction Melting Furnace

Get Price Quote

Jewellery application such as melting of precious metals like gold, silver, copper etc…Steel frame construction and Auto shut feature on fault condition, Robust Industrial design for high and low volume melting, Heat treatment of metal parts and research applications.

Induction Furnace

Get Price Quote

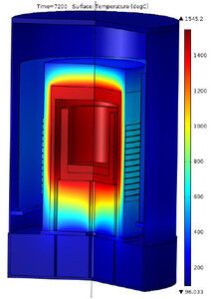

Induction furnaces are employed for vacuum distillation process to recover heavy metals after electro-refining operation. Induction furnace of suitable heating rate and cooled by passive means are required to be developed for this purpose. It is planned to set up a mock up induction furnace which will simulate the conditions to be realized in actual vacuum distillation furnace for this purpose. The mock-up facility will be used to demonstrate melting of 10 kg of copper in a graphite crucible and heated by induction furnace in a vacuum environment. The coil configuration and electrical parameters of the furnace are to be finalized to attain a temperature of about 1500 degC in 2 hours for the charge. Figure1 shows the schematic layout of the mock-up facility used. The furnace liner enclosing the crucible, essentially coupled with the magnetic field generated by coil, gets heated up and indirectly heats the crucible by radiation heat transfer. The melting of copper takes place in crucible. The copper liner prevents the coupling of stainless steel vessel with magnetic flux lines. The carbon felt insulation is used to prevent the heat loss to the coil and other parts. The stainless steel vessel encloses all the above parts. Thermal analysis of the mockup facility is being carried out using COMSOL Multiphysics code to optimize the various electrical parameters. First the Induction Heating Interface under the Heat Transfer Module of COMSOL Multiphysics was modeled and validated with the experimental data reported in the literature. The validated model was then used for 2D-axisymmetric transient thermal analysis of the mock-up facility.

Semiconductor Equipment Spares

1 Per Piece

1 Piece(s) (MOQ)

We can supply all types of parts/spares for the semiconductor equipment, including measuring tools. We can also supply the raw materials like silicon wafers, sputtering targets, chemicals, cleanroom materials, process equipments, etc.

Induction Melting Furnace

Get Price Quote

We are successfully ranked as the top manufacturer and supplier of Induction Melting Furnace. The offered melting furnace is designed to increase the customer’s profitability and improve his market credibility by minimizing down time.

induction melting furnaces

Get Price Quote

induction melting furnaces, Induction Heating Equipment

Induction Melting Furnace

Get Price Quote

induction billet heater, induction hardening equipment, Armature Shaft, Gears

Induction furnace and rolling mills

Get Price Quote

Induction furnace and rolling mills, Steel melting and rolling industry

induction furnaces

Get Price Quote

induction furnaces, Scrap Metals, Transformers, Diesel Generators