Die Casting Products

Get Price Quote

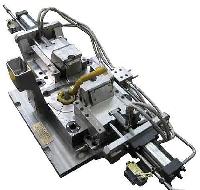

We take up Manufacturing of Aluminum pressure die casted component with support of our associate company which is well equipped with superior quality PDC machine Facility. Our associate manufacturing capabilities allow us to produce, finish and machine aluminum die cast components to meet a wide range of customer specifications. From simple to complex designs. Mastery to provide close tolerances, minimum draft angles, good quality and high strength with the minimal wall thickness necessary" Along with die casting we also offer shot blasting, vibro, machining, electroplating, powder coating, screen printing, anodizing etc. Proven Solutions1. Skilled Experts2. Product Range3. Relationship driven4. On Time Delivery5. Continuous Improvement Consistent quality is maintained and perfect casting starts with design of the component. Our associate craftsmen's are with an innate understanding of the processes and the ability to get the most out of the highest quality equipment.

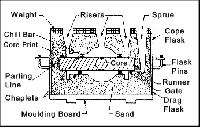

Sand Casting

Get Price Quote

Best Deals from Industrial Casting

Casting Aluminum Molds

100 Per Piece

Aluminum Electric Motor Body Die Castings

Get Price Quote

As a leading Manufacturer, Exporter and Supplier of Aluminum Electric Motor Body Die Castings, we offer a flawless range in the market. The Aluminum Electric Motor Body Die Castings find application in various industries. The high efficiency and durability of the Electric Motors has increased their usage for various applications. Made From 500 grams electric motor die cast body housing Aluminum Alloy component is die casted on our 400 ton Bhuler die casting machine. Features Lightweight Powerful Long working life

Aluminium Sand Casting

Get Price Quote

Die Casting

Get Price Quote

Makino cnc milling precisionmachining-forallmaterialgrades.

Die Casting

Get Price Quote

Aluminum Housing PTO Gearbox Casting

300 Per Kilogram

Die Casting

Get Price Quote

In die casting, molten metal is injected into a mold at a high pressure. The pressure can range from about 1,400 psi to as high as 30,000 psi. By pressurizing the mold, the cast object will be more uniform and will display an attractive finish. In many cases very little or no post-casting machining is needed to complete the item. Pressure molding also provides for precise dimensional accuracy that is critical for parts used in products with interchangeable parts.Aluminum, Zinc and Copper alloys are the materials predominantly used in die-casting.Die-casting can be done using a cold chamber or hot chamber process.Die-c In a cold chamber process, the molten metal is ladled into the cold chamber for each shot. There is less time exposure of the melt to the plunger walls or the plunger. This is particularly useful for metals such as Aluminum, and Copper (and its alloys) that alloy easily with Iron at the higher temperatures. In a hot chamber process the pressure chamber is connected to the die cavity is immersed permanently in the molten metal. The inlet port of the pressurizing cylinder is uncovered as the plunger moves to the open (unpressurized) position. This allows a new charge of molten metal to fill the cavity and thus can fill the cavity faster than the cold chamber process. The hot chamber process is used for metals of low melting point and high fluidity such as tin, zinc, and lead that tend not to alloy easily with steel at their melt temperatures.Die casting molds (called dies in the industry) tend to be expensive as they are made from hardened steel-also the cycle time for building these tend to be long. Also the stronger and harder metals such as iron and steel cannot be die-cast.

Green Sand Moulding

Get Price Quote

Shriram Pistons Limited - Delhi Koyo Vertical Line Kores India Limited - Pune Koyo Vertical Line C. M. Smith & Sons - Nadiad Fritz Hansberg high pressure line Shantala Spherrocast Pvt. Ltd. - Shimoga Foundry Engineering, Sand Plant & Moulding Line Electrosteel Castings Ltd. - Kolkatta Fritz Hansberg core shooter & Moulding Line S.G. Forge (Suzlon Energy) - Coimbatore Pangborn - Europe Tulsi Foundry Ltd. - Sangli Koyo Vertical Line AIA Engineering Ltd. - Ahmedabad Project Engineering Amtek Foundry Limited - Bhiwadi Fomet Press Pour (4 nos.) RPS Vikas Castings - Delhi Koyo Horizontal Line Naetek Ferrocast - Shimoga Foundry Design and Sound Plant HiMac Castings Pvt. Ltd. - Rajkot Koyo Horizontal Line SGK Industries - Shimoga Sand Plant & Moulding Line Kirloskar Ferrous Industries Ltd. - Solapur Fritz Hansberg core making plant Sakthi Auto Components Ltd. - Coimbatore Fomet Press Pour Ashok Iron Works Ltd. - Belgaum Fomet Press Pour RSB Transmission Ltd. Project Management, Project Engg. & Sand Plant

construction castings

Get Price Quote

Our sister company, GCI Castings Inc. was incorporated in 1987 in the state of Kansas, USA. The company manufactured and marketed construction castings to cities and municipalities in USA. The company manufactured over 250 products. In 1993, GCI Exports Pvt. Ltd. was established in Bangalore, India to manufacture Pallets and Headers for pipes. These products were exported world wide. In 1995, GCI Pipe Products Inc. was incorporated in Kansas City, USA to exclusively handle the sales of all Pallets and Headers . In 2004, GCI Castings (India) Pvt. Ltd. was established in Bangalore, India. This captive Foundry unit meets the needs of the pipe plant.

Casting Product

Get Price Quote

Casting Product, metal die, Casting Product, Machining Product

engineering casting

Get Price Quote

engineering casting, Ferrous Castings, Non Ferrous Castings

aluminium sand castings

Get Price Quote

aluminium sand castings, alloy castings, Aluminium Gravity Die Casting

Sand Casting

Get Price Quote

Sand Casting, Gravity die casting, centrifugal die casting, BABBIT LINING

ornamental castings

Get Price Quote

ornamental castings, Ductile Iron Castings, Forged Components, Ceramic Media

Sand mould casting

Get Price Quote

Sand mould casting, magnesium die casting, HRCS Castings

low pressure die castings

Get Price Quote

low pressure die castings, aluminum die castings, diesel engine die casting

machined casting

Get Price Quote

machined casting, Alloy Steel Casting

low pressure die casting

Get Price Quote

low pressure die casting, Precision aluminium, zinc die castings

housing casting

Get Price Quote

housing casting, Real Estate Service

aluminium motor body

Get Price Quote

aluminium motor body, Heat Sinks, Acid etching process

Die Casting

Get Price Quote

Die Casting, automotive product

Metal Casting

Get Price Quote

Metal Casting, Sheet Metal Fabrication, Precision Machining Services

Die Casting

Get Price Quote

Die Casting, Machining Components

Gun Metal Casting

Get Price Quote

Gun Metal Casting, Non Ferrous Casting, aluminium brass casting

engineered aluminum casting

Get Price Quote

engineered aluminum casting, industrial aluminum casting

castings products

Get Price Quote

castings products, Dies, Industrial Products, Die Castings

Green Sand Moulding

Get Price Quote

Green Sand Moulding, Sand Coolers, Screw Conveyors, Green Sand Mixer

Non Ferrous Metal Casting

Get Price Quote

Non Ferrous Metal Casting, non ferrous metals casting, Aluminium Casting