pit furnaces

Get Price Quote

Pit furnaces top-notch quality Conveyor Furnace. These products are widely used for various heat treatments. Manufactured with the latest scientific technologies and high grade raw materials, these products are highly appreciated for excellent quality,

Arc Melting Furnace

Get Price Quote

Best Deals from Industrial Furnace

hardening furnace

500,000 Per Piece

Gas Nitriding Furnace

255,000 Per Piece

vertical vacuum furnace

Get Price Quote

The vertical vacuum furnace designed to use annealing and stress relieving applications. The charge weight up to 500 Kg. The operating temperature is 1250 degree C.

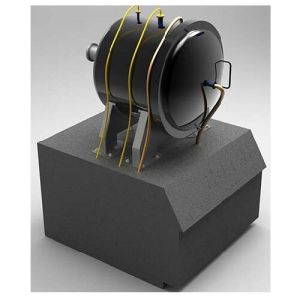

Vacuum Furnace

Get Price Quote

IHVP has designed and supplied various size of Vacuum Furnaces for special applications like, Vacuum Brazing, Annealing, Hardening, Tempering, etc. meeting to the customer requirements. IHVP and Products are worldwide recognized for manufacturing and supplying superb quality Vacuum Furnaces. Our Industrial Vacuum Furnaces are made using the genuine raw material in order to meet international standards of high performance. These Pressure Vacuum Furnaces contain advanced features making them widely adaptable to cater to various requirements of customers.

Industrial Furnace

Get Price Quote

Heatcon High Temperature Furnace Up to 1200°C, furnace is divided into two types: medium temperature (Ambient- 950°C) and high temperature (Ambient- 200°C) Features :- High chromium & high manganese steel castings Cast iron parts Quenching Annealing Ageing and heat treatment of mechanical parts. Research institutes and Labs Specifications :- Fiber ceramic lining, high thermal efficiency, low heat loss and long lifetime. The four-side heating device achieves excellent temperature uniformity. Build a horizontal silicon carbide plate/high temperature cast steel plate for the trolley. Intelligent program temperature controller, which is available to edit and save the multi-segment program. OUR OTHER INDUSTRIAL FURNACES :- Air Circulation Furnaces Furnaces with Radiation Heating up to 1400 °C Pit-Type and Top-Loading Furnaces with or without Air Circulation, Electrically Heated or Gas-Fired Continuous Furnaces, Electrically Heated Laboratory Furnaces Tube Furnaces Bogie Hearth Furnace Pit-type Furnace Bottom loading furnace Crucible furnace

Pit Type Furnace

1,000,000 Per Set

1 Set (MOQ)

Tempering Furnace

Get Price Quote

Box Furnace

Get Price Quote

Finding use in forging applications, these Box Furnace provide for maximum operating temperatures of 1300oC and come win working capacity of 100 TonBatch with heating medium support in form of oilgas.

Drop Bottom Furnace

Get Price Quote

The furnace is inverted type with charge lifting and lowering facility to accommodate the high speed quenching including de-clamping, door opening and quenching. The furnace can be stand alone type with charge carrier loader and quenching tank moving on the floor or floor mounted with charge carrier loader and quench tanks sliding in a pit.

conveyor furnace

Get Price Quote

A multi-zone control environment is present in continuous high temperature furnace, often with a single pre-heating zone, followed by multiple heating zones and then cooling zones before exit.Due to the high temperatures involved most of these furnaces operate under controlled and protective atmospheres, with inert gases such as nitrogen and argon used for initial purging, and gas mixtures or gases like cracked ammonia or hydrogen or endogas used to create a suitable atmosphere as per process parameters.Specially designed corrugated muffles (metallic) are used to withstand thermal expansion for certain processes.

Mesh Belt Conveyor Furnace

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. Application Bright hardening, low case depth carburising, bright quenching and carbonitriding Capacity (Nominal) 50 kg/hr. to 1000 kg/hr. Features Automated operation Automatic process control Consistency of results Controlled atmosphere operation Polymer quench (optional) Available in electrically operated and gas fired versions.

Carburizing Furnace

Get Price Quote

Hightemp-Dowa is an acknowledged leader in Pusher Furnace technology, enabling us to incorporate state-of-the-art facilities in Pusher Furnaces – such as full automatics, pick-and-place robot systems and SCADA. Continuous Gas Carburisers Furnaces are endowed with a single track continuous gas carburising design – enabling consistent production at low operating costs. What’s more, a combination of the latest in sophisticated controls, including data acquisition systems, ensures high quality heat treatment. Features Production capacity 150kghr to 400kghr Operating temperature up to 950oC Sophisticated controls including SCADA & Data Acquisition can be offered Option for Endothermic gas or Nitrogen-Methanol system as atmosphere Option for Gas fired or Electric heating with Radiant tubes Fully automatic, PLC controlled closed loop system Robotic charge handling system for Press Quenching can be offered Ability to process large numbers of different components Modular designs for flexibility and ease of maintenance Silicon carbide skid rails for smooth long lasting movement of charge Pneumatically operated door systems for positive sealing Pusher mechanism designed for heavy loads Automatic adjustment of stroke length to compensate for thermal expansion Guiding of quenching oil throughout the charge with baffles located inside the quench tank

chamber furnaces

Get Price Quote

Chamber Furnaces are offered for a range of heat-treatment applications including stress relieving, normalizing, hardening and tempering. Effective insulation reduces heat loss into the work environment and aids in faster heat-up. Chamber furnaces utilize electrical heating elements or are gas fired/oil fired. Chamber furnaces are designed to provide consistent results through uniform heating, accurate temperature control and control of furnace atmosphere. Features: High quality Reliable Market leading prices

Tempering Furnaces

Get Price Quote

The options available for tempering furnaces are Pit type In-out Box Type Double door straight through Box Type Features • Motorised Roller Driven • Coiled or Radiant Tube type heaters • Can also be used as preheating furnace • Heat Resistant Fan and Baffl e for uniformity of temperature

Batch Type THN Furnace

Get Price Quote

We are offering batch type thn furnace. Thn hightemp toughnite furnace is a pollution free method for soft nitriding of metals. Parts are treated at a temperature lower than the a-1 transformation point in a mixed gas atmosphere consisting of ammonia and endothermic gas. While the resulting carbon and nitrogen react with the steel to carburise and nitride, the diffusion of nitrogen into the material ensures enhanced resistance to abrasion and fatigue. The thn furnace from hightemp provides a completely shielded environment for the work piece backed by a fully automatic operation.

Walking Beam Furnaces

Get Price Quote

We are offering walking beam furnaces. Tenova has installed some of the world’s largest walking beam reheating furnaces for a variety of applications. Our walking beam furnace design combines the latest advancements in hot rider and skid system technology, process control and level 2 automation as well as advanced burner technology.

Vacuum Heat Treatment Furnace

Get Price Quote

LVH has world class vacuum furnaces of "versa treat" brand with latest technology from its own group LVT. Mainly concentrating to ensure consistent metallurgical results as per standards which in turn results in multi fold life of heat treated products. LVH production centres are spread across the country in order to serve the customers at their door step. LVH has well designed systems & components as in very good pumping stations, optimized heat exchangers including the quintessential quenching fan and the optimized heating chambers.

Tempering Furnaces

Get Price Quote

tubular furnace

Get Price Quote

The Heatcon Split round tubular furnace are capable of operating up to 1250 C . The furnace features high temperature furnace rod for long lasting element life. The furnace is supplied from the factory in the horizontal orientation, but can be used vertically. An optional Vertical Stand Bench is available.

Hot Blast Valve

Get Price Quote

Effectively used to isolate the blast furnace from hot blast stove in integrated steel plants and pig iron making facilities using stoves. Also are used as a stove shut-off valve and back draughting valve. For a burner shut-off valve the same design is adopted with wedge arrangements to achieve isolation of gas lines from stoves.

Induction Melting Furnace

Get Price Quote

Jewellery application such as melting of precious metals like gold, silver, copper etc…Steel frame construction and Auto shut feature on fault condition, Robust Industrial design for high and low volume melting, Heat treatment of metal parts and research applications.

Annealing Furnaces

Get Price Quote

gas carburizing furnace

Get Price Quote

gas carburizing furnace, hardening furnace, paint drying ovens

Electric Induction Furnace

Get Price Quote

vaccum furnace

4,000,000 Per Piece

Metal Melting Furnace

400,000 Per Piece

Vacuum Furnace

Get Price Quote

INDVAC has designed and supplied various size of Vacuum Furnaces for special applications like, Vacuum Brazing, Annealing, Hardening, Tempering, etc. meeting to the customer requirements. INDVAC and Products are worldwide recognized for manufacturing and supplying superb quality Vacuum Furnaces. Our Industrial Vacuum Furnaces are made using the genuine raw material in order to meet international standards of high performance. These Pressure Vacuum Furnaces contain advanced features making them widely adaptable to cater to various requirements of customers.

Vacuum Heat Furnace

6,500,000 Per unit