continuous furnaces

Get Price Quote

Production capacity 150kghr to 400kghr Operating temperature up to 950oC Sophisticated controls including SCADA & Data Acquisition can be offered Option for Endothermic gas or Nitrogen-Methanol system as atmosphere Option for Gas fired or Electric heating with Radiant tubes Fully automatic, PLC controlled closed loop system Robotic charge handling system for Press Quenching can be offered Ability to process large numbers of different components Modular designs for flexibility and ease of maintenance Silicon carbide skid rails for smooth long lasting movement of charge Pneumatically operated door systems for positive sealing Pusher mechanism designed for heavy loads Automatic adjustment of stroke length to compensate for thermal expansion

Industrial Furnaces for Steel Industry

Get Price Quote

We are among the pioneers in the industry for manufacturing and supplying industrial furnaces for steel industry. The offered furnaces are used in steel processing industry and are exceptional in terms of durability. These furnaces have been designed by our expert professionals in adherence to the set industry norms. The offered furnaces offer hassle-free operations and are resistant to abrasion.

Best Deals from Industrial Furnace

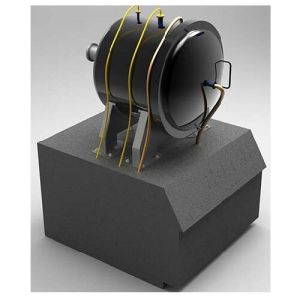

rotary hearth furnace

Get Price Quote

Rotary Hearth furnaces have a rotating hearth with adjustable speed and widely used for reheating and hardening pre-carburised large sized components that require press or plug quenching. Rotary Hearth furnaces from HIGHTEMP are available in a capacity range of 80-500 kghr. Features Separate doors for loading and unloading prevents product mix up Atmosphere options for Nitrogen Methanol Endogas gas system available Can be custom built to suit individual applications Maximum temperature 900ºC

vaccum furnace

4,000,000 Per Piece

Rotary Kiln Furnace

400,000 Per Piece

Vacuum Induction Melting

Get Price Quote

HHVs Vacuum Induction Melting (VIM) has a reliable process and very versatile.It can be used for producing a wide range of materials, including special alloys that are cast for high value critical parts such as golf club heads, aerospace parts, automotive parts, and other equipment components that need special mechanical properties for successful operations.

chocolate melting machine

Get Price Quote

Melting Batch Furnace

Get Price Quote

vacuum furnaces

Get Price Quote

We are an eminent and leading trader of Vacuum Furnaces

Vacuum Heat Treatment Furnace

200,000 Per Piece

silver melting furnace

Get Price Quote

Therelek medium and high frequency Induction melting furnaces provide quality Induction melting. This is done to obtain maximum productivity, minimum energy consumption and in addition offer trouble free performance of the furnace. We make competent Induction melting furnaces for prosperous foundry operation and customer satisfaction that is need of the hour in foundries.

chamber furnaces

Get Price Quote

Chamber furnaces are used for batch type operations. These furnaces can operate up to 1900°C. They can be of rugged, refractory based construction or lightweight ceramic fiber board and insulation based construction.

Stress Relieving Furnaces

Get Price Quote

We are engaged in providing the high quality stress relieving services to our esteemed clients. Our stress relieving process is widely renowned in the industry. Machining induces stresses in parts. These stresses can cause distortions in the part long term. If the parts are clamped in service, then cracking could occur. Also whole locations can change causing them to go out of tolerance. For these reasons, stress relieving is often necessary. Our team provides the stress relieving techniques as per the latest industry standards.

Hardening Furnaces

Get Price Quote

Hardening furnaces The offered furnaces are made by using high quality material in compliance with all the national and international quality standards and norms and are durable in nature and sturdily constructed. This is commonly used for heat treatment of steel alloys and involves heating the steel to a pre-determined temperature, then cooling it rapidly. Further, this product is available at the most affordable prices.

gas carburizing furnace

15 Per Piece

We manufacture Electrically Heated Pit Type Furnace for Gas Carburising as well as neutral hardening Furnace. The above furnace also has Carbon Potential Control. This comes with a self-standing control panel fitted and wired for main S/F unit. The above furnaces can be customised and are usually built as per customer requirement.

Gas Pit Furnace

Get Price Quote

Vacuum Heat Furnace

6,500,000 Per unit

Mesh Belt Conveyor Furnace

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. Application Bright hardening, low case depth carburising, bright quenching and carbonitriding Capacity (Nominal) 50 kg/hr. to 1000 kg/hr. Features Automated operation Automatic process control Consistency of results Controlled atmosphere operation Polymer quench (optional) Available in electrically operated and gas fired versions.

conveyor furnace

Get Price Quote

A multi-zone control environment is present in continuous high temperature furnace, often with a single pre-heating zone, followed by multiple heating zones and then cooling zones before exit.Due to the high temperatures involved most of these furnaces operate under controlled and protective atmospheres, with inert gases such as nitrogen and argon used for initial purging, and gas mixtures or gases like cracked ammonia or hydrogen or endogas used to create a suitable atmosphere as per process parameters.Specially designed corrugated muffles (metallic) are used to withstand thermal expansion for certain processes.

pit furnaces

Get Price Quote

Pit furnaces top-notch quality Conveyor Furnace. These products are widely used for various heat treatments. Manufactured with the latest scientific technologies and high grade raw materials, these products are highly appreciated for excellent quality,

Vacuum Furnace

Get Price Quote

INDVAC has designed and supplied various size of Vacuum Furnaces for special applications like, Vacuum Brazing, Annealing, Hardening, Tempering, etc. meeting to the customer requirements. INDVAC and Products are worldwide recognized for manufacturing and supplying superb quality Vacuum Furnaces. Our Industrial Vacuum Furnaces are made using the genuine raw material in order to meet international standards of high performance. These Pressure Vacuum Furnaces contain advanced features making them widely adaptable to cater to various requirements of customers.

pit furnaces

Get Price Quote

Tempering Furnace

Get Price Quote

Induction Melting Furnace

Get Price Quote

Jewellery application such as melting of precious metals like gold, silver, copper etc…Steel frame construction and Auto shut feature on fault condition, Robust Industrial design for high and low volume melting, Heat treatment of metal parts and research applications.

Bogie Hearth Silicon Carbide Furnaces

Get Price Quote

Bogie Hearth Silicon Carbide Furnaces are offered for a range of heat treatment applications including stress relieving, normalizing, hardening and tempering. The heat loss into the work environment and aids in faster heat up is reduced by effective insulation. Bogie Hearth Silicon Carbide Furnaces utilize electrical heating elements or are gas fired/oil fired. To provide consistent results through uniform heating, accurate temperature control and control of furnace atmosphere these Bogie Hearth Silicon Carbide Furnaces are designed. Features: Quality product Highly reliable Reasonable price

Electric Furnaces

Get Price Quote

Materials which is used for manufacturing electric heating elements such as Ni-chrome, Platinum, Kanthal, Cupronickel. Many heating elements such as electric oven, electric furnace, electric heaters etc uses the electrical energy to produce the heat. The working principle of heating element is based on the heating effect of electric current. It produces the heat, when current is passed through a resistance. Electric Heating Elements Suppliers in India, providing diverse collection of electric furnaces and other electric heating element.

Muffle Furnaces

Get Price Quote

We supply rectangular light weight muffle furnaces to wide range of industrial laboratories. It is made of thick mild steel casing and is reinforced with iron angles rivets and screw joints. It is enamel paint coated to avoid rust. It has maximum working Temperature of 1500 C. The door, counter balanced for easy operation opens sideways with the hot surface away from the person operating. Specifications : The lower portion of the chamber is perforated for protecting the temperature control unit from very high beam of light Kanthal wire is used to make heating elements Most uniform distribution of heat and protection of heating elements against damage and chemical deterioration or distortio Special high temperature alloy-completely surround the heating chamber

Aluminium Melting Furnaces

Get Price Quote

Pit Type Furnace

Get Price Quote

Uniform heating throughout the retort with electrical heating coils. •Fully automated control system with Thyristor control with PID Temperature control,Carbon controller with proportional value. •Cast fan for uniformity of temperature and atmosphere. •Hydraulic Operated Doors. •Options for using carbodrip, LPG & methanol, Methanol & Acetone atmosphere. •Low cost spares with easy availability. Applications Carburising Case hardening Annealing Hardening Tempering Normalising Stress Releaving

Tube Annealing Furnace

Get Price Quote