Aggregate Jaw Crusher

Get Price Quote

1 Piece (MOQ)

HJ Series Jaw Crusher

Get Price Quote

By analyzing customers’ requirements and absorbing the world-class advanced technology, SBM developed the HJ series jaw crusher. This machine has larger capacity but the energy consumption is quite low. It is to be the ideal substitute products for old ones. Features Better performance than old ones: according to an in-depth study, SBM optimized motion trail of the movable jaw and the cavity of the machine. The weight of counterweight and the structure of the Jaw crusher are adjusted, the vibration of whole machine is greatly improved and the performance is also well improved. Utilize new bolt system, operators can replace the toggle easily. Application HJ series jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

Best Deals from Jaw Crusher

Jaw crusher

Get Price Quote

Reckoned for their corrosion free body, high mechanical strength and easy assembly, our Jaw Crushers are of unmatched standards. Our company is one of the eminent Manufacturers and Suppliers of a wide range of Jaw Crushers. Available with us in varied specifications, the Jaw Crushers are made under expert supervision using the latest technologies. Features of Jaw Crusher : Simple structure. Durable. Low operation costs. Simple maintenance. Long service life. Application :The jaw crusher produce by Wangda Machinery has wide application fields . It is used to crush materials with compressive strength below 250Mpa, and it can break the different sized material into uniform particle sized materials to the next process in the breaking making line.

Jaw crusher

Get Price Quote

Creative offers complete range of single toggle jaw crushers for all types of rock, ores & minerals. These crushers are designed to operate in most rugged environment and need less maintenance. Creative Jaw crushers are extremely heavy-duty machines and hence robustly constructed. Creative 's range of single toggle jaw crushers are designed with an upward facing toggle system. This produces a "Flat Elliptical Movement" at the bottom of the swing jaw which increases the efficiency of the crushing. The Unique Elliptical motion of the swing jaw guarantees a highly efficient production rate at every setting. This special motion of the jaw also minimizes scrubbing action common in single toggle jaw crushers.

BB 100 Jaw Crushers

Get Price Quote

The powerful RETSCH Jaw Crushers are designed for the rapid, gentle coarse and primary crushing of hard, brittle and tough materials. The breaking jaws are available in a variety of materials which include heavy-metal-free steel. Their efficiency and safety makes these pulverizers ideal for sample preparation in laboratories and industrial plants. Four basic models are available: from the compact bench-top model BB 50 to the biggest floor model, BB 300 which allows for feed sizes up to 130 mm. RETSCH jaw crushers combine increased operating convenience with maximum working safety.

Pew Jaw Crusher

Get Price Quote

We are offering pew jaw crusher. Features v-shaped structure crushing cavity is able to meet a big feeding. Movable jaw assembly adopts a high-quality steel casting and heavy eccentric shaft has also adopted forging billet for processing. Use of finite element analysis technology helps to reach both light weight and high reliability. Equipped with wedge adjustment devices, enable to realize automatic control and stepless adjustment.

single toggle jaw crushers

Get Price Quote

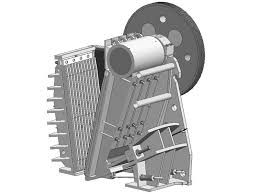

Features Dry rolling toggle…rolling contact requires no lubrication. High alloy iron toggle plate rides on hardened steel seat. Self-aligning spherical roller bearing in frame and moving jaws. Dual lip-type seals enclose bearings…lubricant stays in… dirt stays out. Grease lubricated bearings standard… oil lubrication optional. Welded frame is heavy steel plate – stress relieved before machining. Mortise and tenon construction provides strong, rigid frame assembly. Moving jaws is heat – treated cast steel. Eccentric shaft is forged alloy steel. Abrasion-resistant side liners protect side frames from wear. Heavy cast flywheels… smooth operation even under momentary overloads. Counterbalancing reduces vibration. Steel shims for setting adjustments and wear compensation, Hydraulic jack facilities Adding or removing shims. Replaceable wear plates behind jaw plate protect moving jaw and frame. Corrugated manganese jaw plate is reversible for longer life. Top is retained by wedge… replaceable support strip retains bottom. Replaceable deflector plate prevents damage and wear to top portion of moving jaw.

Jaw crusher

Get Price Quote

According to well-knit processing technology and 30 years’experiences about research and development production, C6X Series Jaw Crusher was produced by optimizing structure. The equipment takes advantages of higher quality, longer life, lower cost and higher efficiency at the same energy consumption. Aiming at the hard materials, C6X Series Jaw Crusher has become typical equipment of perfect crushing because of high crushing ratio and quality wear resistant parts, which provides easier production process for customers. Processed Materials : Iron ore, copper ore, gold ore, manganese ore, river stone, gravel, granite, basalt, minerals, quartz, diabase, etc.. Applications : Mining, metallurgy, construction, chemical, cement, refractory material, ceramics, etc. Features 1.Optimizing crushing chamber and trajectory parameters of moving jaw can get reasonable inertial moment and crushing stroke, and higher efficiency will be obtained when energy consumption is equal to others.2.Replacing welded machine with bolted fastening, the structure is more compact because the problem about stress concentration caused by welding is avoid.3.Replacing plates with wedges, the discharge opening can be adjusted simply, efficiently and safely.4.Quality materials and components are chose, and main parts are changed easily, which reduce costs effectively.5.Replacing anchor connection with elastic position limiters and rubber damping, the crusher has reduced the impact that influences other components, which can improve its service life.6.Integrative motor cabinet reduces mounting space. Working Principle Input dynamic by motor, the pulley drives eccentric shaft to make the movable jaw move upwards and downwards with SPC belt. When the movable jaw moves forth toward the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, the chopped or squashed materials which met the requirements will be discharged from the outlet. Since the motor keeps working, the crusher will crush and discharge periodically to achieve mass production.

Double Toggle Jaw Crusher

Get Price Quote

Leveraging on our technical expertise and competent work force, we are leading manufacturers and suppliers of Double Toggle Jaw Crusher used at primary or secondary stages of crushing. Designed as per quality standards set by the industry, these Double Toggle Jaw Crusher are manufactured using quality raw material procured from reliable vendors. It is appreciated for its high performance, reliability and long life service. Our customers can avail these Double Toggle Jaw Crusher at reasonable prices from us. Benefits of using Double Toggle Jaw Crusher Jaw crusher is used at a primary or secondary stage crushing. It has a large intake to crush large lump size and produce small lumps The material is broken between a stationery jaw and swing jaw. Stationery jaw, as the name suggests, remain fix all the time and the swing jaw acts as a pendulum. The material is crushed between the stationery jaw and swing jaw till it gets reduced to the discharge opening at the end. The hanging swing jaw acts like a pendulum that provides greater shock at the bottom of the jaw. This mechanism overcomes the rubbing problem of stones to the jaw plate and thereby provides longer life to the jaw plate. Double toggle design, even for the smallest size crusher, distributes the load to different spares and protects them against the possible wear. Salient features of using RCI Jaw Crusher: Proven Manufacturing The innovative machine design, the skilled craftsmanship and proven manufacturing are ample reasons for its unique performance thereby delivering the best results to the users. The productivity and functionality of the machine depends largely on the depth and length of the cavity. The proportion of the depth and the length of the cavity is designed in accordance with the intake opening of the machine thereby providing the desired productivity with greater fault resistant functionality Well designed compression springs provide crushing mechanism that eliminates the knocks and resultant water Quality Material & Manufacturing Machine body frame is made of specialized steel plates with adequate thickness and usage of supporting ribs to support the proper functionality with out any breakage. All assembled parts are molded and acted as a single homogeneous entity as compared to fabrication. Parts made from fabrication process uses several joints to form a complete entity thereby comparatively weak to withstand against different wear and breaking conditions as compared to the molded parts. Casted Body blocks are well welded with the machine body frame to create a structure full of strength Jaw plates and side wear plates in the cavity area are made from specialized material- Mn steel, to withstand against possible wear. Shaft, toggle and pitman is made of quality steel alloys providing seamless functionality, with out the fear of fault or breakage. Toggle pin and flywheel is made of alloy of Bronze metal to reduce possible wear and provide longer durability High quality rubber diaphragm provides oil sealing with capacity to withstand against hot oil condition and yet delivering functionality Proven bearings to provide smooth working Flexible design for usage & maintenance Easy mechanism to adjust the discharge opening with adding or removing the setting flats Easy inspection for the oil flow of the machine Adequate swing jaw design that fits different types of jaw plates on it to produce different type of output Safety mechanism Safety mechanism fitted in the flywheel protects the machine by stopping its operation, when a non-crushable material is feeded in to it Oil sensor mechanism to alarm and stop working of the machine in case of lubrication problem of oil on to the eccentric shaft

Jaw crusher

Get Price Quote

The jaw crusher produce by Wangda Machinery has wide application fields . It is used to crush materials with compressive strength below 250Mpa, and it can break the different sized material into uniform particle sized materials to the next process in the breaking making line. Features of Jaw Crusher: Simple structure. Durable. Low operation costs. Simple maintenance. Long service life.

Jaw crusher

Get Price Quote

Industrial Jaw Crusher is primarily used for crushing of huge lumps of slag. Our Double-Toggle Jaw Crusher is a heavy duty machine that effortlessly crushes large slag lumps into small pieces. The Jaw Crusher that we manufacture is supplied to various other industries where it is used for crushing rock, coal, refractory, stone & glass, etc. Our Jaw Crushers are easy to operate and require negligible maintenance. They are highly efficient and have proved their worth by working smoothly at the client�s end. We have been able to carve out a special place among the prime Jaw Crusher Manufacturers and Suppliers in India.

Pe Jaw Crusher

1 Per Piece

1 Piece(s) (MOQ)

1. High reduction ratio, uniform discharging granularity and low power consumption 2. It is widely used in metallurgy, mine, building materials and so on.

Jaw crusher

175,000 - 375,000 Per piece

1 Piece (MOQ)

Single Toggle Jaw Crusher

2,500 Per Piece

HJ Series Jaw Crusher

Get Price Quote

HJ Series Jaw Crusher, YKN Vibrating Screen

jaw roll crusher

Get Price Quote

jaw roll crusher

Jaw crusher

Get Price Quote

Bucket Elevator, suction drums, mini cement plant machinery

Jaw Crushers

Get Price Quote

Jaw Crushers, Cone Crushers, vertical shaft impact crushers

Jaw crusher

Get Price Quote

Secondary Jaw Crusher

Get Price Quote

Secondary Jaw Crusher, Horizontal Shaft Impact Crusher, Primary Jaw Crusher