VIBRATION MEASURING SYSTEMS

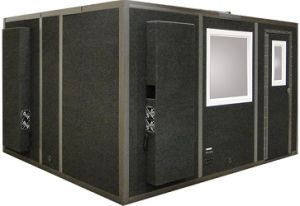

LETs has PC Based Noise and Vibration measuring systems for automotive components, Aeronautics and consumer products. We will supply the sound proof systems with PC Based National Instruments software for measurement systems. The Noise and Vibration measuring system can be used in the end of line test in the final assembly line to check the quality of products. Our Assembly Line Noise Test Chamber has well designed with precise precision to provide specific data. It is used mostly in the automotive Component industry and in other electric motor manufacturing industries. It is made of an acoustic dampening base material providing both on line and off line testing facilities. The assembly line noise test chamber is used for identifying defects in the machine parts using sound testing. FEATURES OF ASSEMBLY LINE NOISE TEST BOOTH our assembly line noise test booths are built with a robust design for superior performance and with all the required features. Automatic window: The sound proof window remains automatically closed during equipment sound testing. The opening and closing of the windows is directly linked with the functioning of the test chamber. The acoustic performance of the window is nearly 40 dB(A) at an ambient of 75 dB(A). Conveyor belt: The Assembly line noise test chamber has a conveyor belt that allows the entry and exit of the products to the test chamber. The conveyor has automatic sensors to stop and start. Hinge type opening: The opening of the assembly line noise test booth has pneumatic cylinders to control the opening. The entry and exit window have a lever that is used to control it. The sound control performance of this opening is 35 dB(A) with an ambient of 85 dB(A).

...more

Machine Vision System

LETs provides innovative solutions with Machine vision system for manufacturing industry to improve their part quality during the assembly process. We offer the solution with NI vision builder software tools and dedicated PC & camera system. We make the feasibility study of your requirements and then make proposal, Design and implement the application. AN INTRODUCTION TO MACHINE VISION SYSTEMS Machine vision is the incorporation of computer vision into industrial manufacturing processes, although it does differ substantially from computer vision. In general, computer vision revolves around image processing. Machine vision, on the other hand, uses digital input and output to manipulate mechanical components. Devices that depend on machine vision are often found at work in product inspection, where they often use digital cameras or other forms of automated vision to perform tasks traditionally performed by a human operator. However, the way machine vision systems ‘see’ is quite different from human vision. The components of a machine vision system can vary, but there are several common factors found in most. These elements include: Digital or analog cameras for acquiring images A means of digitizing images, such as a camera interface A processor When these three components are combined into one device, it’s known as a smart camera. A machine vision system can consist of a smart camera with the following add-ons: Input and output hardware Lenses Light sources, such as LED illuminators or halogen lamps An image processing program A sensor to detect and trigger image acquisition Actuators to sort defective parts

...moreBe first to Rate

Rate ThisOpening Hours