Boring Bars

Get Price Quote

Boring Bars are single point boring tools used for enlarging pre-existing bores, usually in turning operations. They are designed with various insert and clamping configurations. The shanks can be made of steel, a combination of steel & carbide as well as heavy metal depending on the required bore depth.

High Speed Steel Cg Blades

Get Price Quote

1 Piece(s) (MOQ)

We are offering high speed steel cg blades. We are leading manufacturer of work rest blade in bangalore we supply to the top most companies in bangalore and various small scale industries all over india. We manufacture all type of work rest blade like thread rolling, in feed and through feed. we also do re condition of work rest blades(re-tipping and re grinding). We will manufacture the blade according to the drawing you provide. We will give you a very competitive price.

Best Deals from Laser Cutting Tool

End Mill

Get Price Quote

Our End Mill is one of the highly demanded products of our company. The mill that we provide is manufactured using premium metal and other raw materials ensuring the finest quality and durability. It has wide industrial application. Our mill is available in different sizes, dimensions and other specifications as per the requirement of different buyers. The End Mill That we provide is highly durable in nature.

Spot Facing Tools

Get Price Quote

We deal in the finest quality Spot Facing Tools in the national market. Our Back Spot Facing Tools are used for back spot facing / chamfering on jobs using drilling machines, Machining centers, Boring machines etc. Their cycle of working can be programmed. Additionally, we are a prime Forward Spot Facing Tool Manufacturer in India. Rear spot facing around the hole is a cumbersome operation while adopting the conventional boring bar with HSS blades or cutters. The time required for fixing, setting and removing the blade/cutter is very high; being HSS, the cutting is very slow; and, whenever the cutting edge becomes blunt, it requires expensive and time � consuming regrinding. All these result in the very high down time of the main machine. The automatic back spot facing tool is specially designed to make the back spot facing operation faster and cheaper. Since it totally eliminates manual interruption during back spot facing operation, not only expensive machine down time is saved, but also it is the most ideally suited tool for back spot facing operation on programmable /CNC machining centers. As the most of tools are offered with standard carbide insert, all the advantages of insert tooling will be available. Construction The back spot facer consists of a case hardened and ground alloy steel shank, which takes location in the hole on which back spot facing is carried out. Provided in the pilot shank is a recess, for accommodating the insert holder or wing. Clamped on the wing is standard carbide insert with the help of a clamp screw. Being LH threaded, it holds the insert in a correct position. In the recess, the wing is eccentrically pivoted on hardened and ground pivot pin and pivot screw. A suitable clearance is provided on the pilot shank to enable it to freely rotate in a drilled hole. These tools are so designed that with various combination of pilot shanks, it is possible to obtain different back spot facing combinations. Sizes and Specification The back spot facing diameter is offered in relationship to its pilot shank diameter � i.e. at ratio 2:1. In other words, back spot facing is possible with this type of tool up to approximately twice the diameter of the nominal diameter of the pilot, subject to some design restrictions. Tools below 12mm pilot are normally offered with solid HSS wing, having integral pivot pin. Operations The automatic back spot facing tool, rotating in reverse direction, is inserted in to the hole. The wing, even it opens in rotation, instantly folds into the recess as it touches the rim of the hole in the work piece. After the wing clearly comes out of the pilot hole, the spindle rotation is reversed to forward direction. Then the wing swing out of the recess due to centrifugal force. With feed it cuts. On completion of the spot facing operation, the spindle rotation is reversed and the tool is withdrawn. During the back spot facing, since cutting force tends the tool to pull down of the spindle, it is adviceable to fix the tool in the machine spindle with a cotter/drive key/draw bolt. It may be noted that the smaller size tools are running at comparatively higher speeds. Here, the wings, therefore, swing out easily due to high centrifugal force. However, large tools operate in lower speeds, which mean centrifugal force acting on the wing may be insufficient, particularly when the tools work in horizontal position, thus resulting the wing to remain in the recess. To overcome this problem, tools above 300mm pilot are provided with spring washer as shown in the sketch. The spring washer keeps the wing open after it comes clear of the pilot hole, irrespective of the speed at which the tool is being rotated.

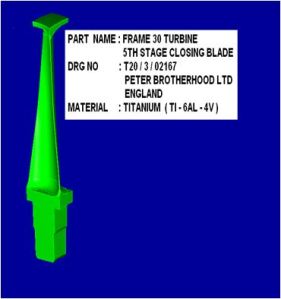

Gas Turbine Blades

Get Price Quote

We are offering gas & steam turbine blades in steel , titanium, nimonic , inconell etc. also blisks and shrouds for turbines. Other precision parts for turbines.

Laryngoscope Blades

Get Price Quote

Buyers can rely on us for on-time delivery as we are assisted with up-to-date transit and logistics services. Combining our expertise with the technology that we possess, we take the responsibility to deliver utmost quality Laryngo scope to the customers.

segmented diamond saw blades

Get Price Quote

We manufacture and export Segmented Diamond Saw Blades for wet cutting. Segmented Diamond Saw Blades are mainly fit for manual machines. Segmented Diamond Saw Blades are available for single saw blade, multi saw blade, gang saw, grinding disc, core drill bits. The Segmented Diamond Saw Blades offered by us make cutting easier. We deal in Domestic and International Market. Benefits Less Noisy High Productivity Smooth, Easy and Fast cutting Supreme Quality

Boring Bars

Get Price Quote

High Power Fiber Laser Cutter

Get Price Quote

CF-3015E series of High power fiber laser cutting machine is tailored according to the sheet metal market needs a fiber laser cutting machine with international standards. This series of products for the metal processing industry, the preferred model. Interactive swap table(Auto-exchanger) significantly reduces time required, increase productivity more than 30%effective, and have a strong cutting ability. Set fast cutting speed, very low operating costs, excellent stability, high-quality processing and a strong ability to adapt to one. The use of closed-loop dual-drive system architecture, equipped with imported open CNC system to ensure precision in high-speed motion conditions, instead of stamping punch cutting, cutting stampings higher productivity of other brands of laser equipment compared to processing Better accuracy. Using surround design, in line with European CE standards, safe and reliable processing, switching configuration table, loading time and processing time superimposed, to further improve production efficiency. For high-speed movement requirements, design and manufacture of welding reinforced bed, two aging treatment, to ensure the accuracy and stability of the bed in a long-running laser equipment brands. The three kinds of cutting assist gas (high-pressure air, nitrogen, oxygen), the control system can be automatically converted to use to meet customer demand for a variety of materials processing, simple operation, lower cost. Standard metal professional automatic typesetting software (including materials management, process optimization and other functions), provide process parameters library which allows the operator to simpler, easier to manage. Optimization of optical lenses, specially designed nozzle and sensor technology, cutting smoother, more stable. Applicable materials Mainly used for carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, baking plate, galvanized sheet and other metal materials, rapid cutting. Wherein 1KW lasers with anti-high anti-ability, can be cut on the steel, aluminum. Industry application Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automotive, machinery, precision fittings, ships, metallurgical equipment, elevators, kitchen utensils, household appliances, craft gifts, tool processing, decoration, advertising, metal processing Various manufacturing and processing industries.

Pcd Tools

Get Price Quote

We offer pcd tools. Pcd tools & inserts

profile cut components

Get Price Quote

Product Description: We specialize in providing Profile Cut Components that are manufactured using high-grade steel and within a tolerance range of 1mm. These are available in varied thicknesses ranging from 3 mm to 300 mm and sizes ranging from 6.5 meters to 18 meters. Our range of Profile Cut Components is extensively used in electrical, power & agricultural industries and earth moving sector. Being a renowned service provider, we undertake job work as per the specifications laid down by the customers.

Laser Cutting Components

Get Price Quote

We also offer an exclusive range of Laser Cutting Components, which is available in various dimensions and can be personalized as per the requirement of our valued clients.These are fabricated using best grade raw materials in compliance with industry standards.

profile cutters

Get Price Quote

profile cutters, Wood Cutting Tools, Wood Working Machines

Gear Cutting Tools

Get Price Quote

Gear Cutting Tools, grinding tools, cnc control systems, Tool Presetter

Engineering Cutting Tools

Get Price Quote

Engineering Cutting Tools, Precision Components, Jigs, Machined Components

Cnc Tools

Get Price Quote

Cnc Tools, cnc rotary tables, Rotary Table, power generation products

precision turning tools

Get Price Quote

precision turning tools, Hydraulic End Fittings, hydraulic bending machines

Solid Carbide Tools

Get Price Quote

Solid Carbide Tools, fine boring tools, precision machine tool, Reamers

Boring Bar

Get Price Quote

Boring Bar, special tools, Boring Tools, Tool Holder, End Mills