hose forming machine

Get Price Quote

This Annular Corrugated Hose is manufactured by continuously processing the material on a high speed automatic forming machine. The annular corrugations do not get twisted when subjected to elongation and contraction, has better pressure capacity and can be fitted with re-usable fittings. They have good flexibility, high strength, and are heat resistant and pressure tight. These Hoses can be used to convey most kinds of fluids, gases and liquids, chemicals etc. and can function to absorb reciprocating motion, thermal expansion, vibration and misalignment.

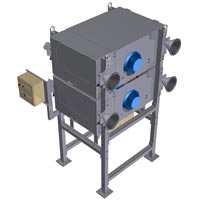

Metallic Bellow Forming Machine

Get Price Quote

Metallic Bellow Forming Machine was developed to obtain uniform and accurate bellow with mechanical cold forming with an completely automated process. The machine has an hydraulic cylinder, which will open and close the bellow die. The bellow die expands to form the bellow. The actual bellow blank, a stainless steel sheet metal seam welded in cylindrical shape, rests on a rotary indexing table which inturn is mounted on a vertical indexing slide. This indexing slide, is driven by a servo motor connected to a ballscrew. The sliding surfaces are made of LM guides and blocks for smooth and fast indexing. The servo motor, hydraulic expansion and indexing table rotation is seamlessly integrated with a PLC for complete auto-cycle function. A 7″ touchscreen HMI is provided, so that parameters such as bellow pitch, number of rotations and angle of rotation per expansion, speed of indexing, etc can be easily entered and set. FEATURES & SPECS: Rigid, heavily ribbed, stress relieved and fabricated structural. Atop the base, a fixture is mounted on a vertical slide. This vertical slide is servo driven in combination with ballscrew for high positional accuracy. On this carriage of the vertical slide, a fixture is mounted which can hold the job and rotate it. The rotation of the fixture is motorized and will be integrated into the PLC auto-cycle. At the center of the fixture, a die is mounted with a hydraulic press. This die has a wedge type arrangement to open and close. PLC programmed auto-cycle will be provided for the machine. SEQUENCE OF OPERATION: Set the required pitch on the HMI. Load the job and press auto-cycle. The vertical slide moves the job & fixture to the position for first bellow formation. The press moves down and the die expands for the form the sheet metal. Now, the die retracts slightly to free the component, but still remains within the groove. Now the fixture indexes by preset angle and the die expands and contracts for ‘N’ number. Now, the fixture indexes again and the die expands and contracts again. The above step is repeated as per the preset parameters. Now the die completely contracts and the vertical slide moves the component to the next pitch. The forming process repeats again for the rest of the bellow form.

Best Deals from Lock Forming Machine