SLOTTED ANGLE SHELVING RACKS

Slotted angle Shelving Racks are Light Duty Storage System, fabricated; thereafter the sheets are systematically tested, degreased, de-resulted and chemically treated. These are applied in departmental store shelving, multi-tiers shelving, drawer racks, tool cabinet etc.Before meeting us and seeing our work, our customers had never experienced Slotted angle Shelving Racks of this kind, which is high in terms of workmanship, quality and reliability. Accessories : These are suitable for partitions plates, cladding sheets, These are suitable for corner plates, nuts and bolts, plastic fleet, label holders etc.. Ideal for Palletized and Non-Palletized Stores.

...more

Mobile Compactors

STO-compactor , these are mobile trolley (chassis) mounted shelving systems that move on rails that provide maximum storage capacity. These systems have only one access corridor thereby increasing efficiency of the storage. These are completely safe to use. The entire compactor is clad with powder coated steel sheets with decorative laminates. The shelving panels & slotted angles are stove baked or enamel painted. This saves money by releasing valuable space for profitable production or by eliminating expensive building extensions. It is smooth, noiseless and easy to maintain.

...more

Mobile Compactor Storage System

STO-compactor , these are mobile trolley (chassis) mounted shelving systems that move on rails that provide maximum storage capacity. These systems have only one access corridor thereby increasing efficiency of the storage. These are completely safe to use.The entire compactor is clad with powder coated steel sheets with decorative laminates. The shelving panels & slotted angles are stove baked or enamel painted. This saves money by releasing valuable space for profitable production or by eliminating expensive building extensions. It is smooth, noiseless and easy to maintain. A boltless, chip-on heavy duty storage systems that are easy in installing and shifting. Custom built for any load, width and height. Ideal for Palletized and Non-Palletized Stores. Cold formed light gauge sections with high strength to weight ration.

...more

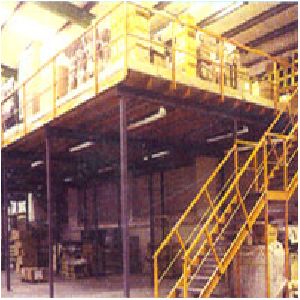

Mezzanine Floor

Most widely used floor for storing all kinds of materials is mezzanine floor. The STO Mezzanine floor is constructed with plywood and steel. The space is designed according to the load per sq.mt. and height. The unique aspect of mezzanine floor is that the floor can be relocated to meet varying requirements. Rack-supported mezzanines are the most economical way to create an additional floor level using standard pallet rack components. Metal Impacts has experience in designing, and maximizes your storage space. Rack-supported mezzanines can be built over existing equipment and work areas. rack-supported mezzanines can eliminate downtime and expensive relocation costs. Engineering and installing industrial rack supported mezzanine systems that utilize the cubic area of warehouses. Maximizes your storage space. By improving workflow efficiency and space utilization. Cold formed light gauge sections with high strength to weight ration.

...more

metal storage rack

STO Adjustable pallet racking is probably the most widely used type of pallet racking, and offers free access to every pallet held. It can be built to match the lift height of any fork-lift truck Stackers. It consists of upright end frames and pairs of horizontal beams on which the pallets are located, and beam heights are adjustable to suit the height of the pallet loads being stored.

...more

metal shelving rack

In theory, to optimize the use of vertical space, beam heights can be altered if pallet load heights change. In practice, this does not often occur because of the cost and disruption to the operation. Typically, two pallets are stored per bay (ie between rack uprights). The conventional way of laying out APR is to have one row single deep against the wall at each end of the installation, with back-to-back rows in between. This gives every truck aisle access to two rows of racking, and minimizes the number of aisles required. APR is a flexible, versatile storage system, which gives excellent stock access.

...more

Metal Rack

In theory, to optimize the use of vertical space, beam heights can be altered if pallet load heights change. In practice, this does not often occur because of the cost and disruption to the operation. Typically, two pallets are stored per bay (ie between rack uprights). The conventional way of laying out APR is to have one row single deep against the wall at each end of the installation, with back-to-back rows in between. This gives every truck aisle access to two rows of racking, and minimizes the number of aisles required. APR is a flexible, versatile storage system, which gives excellent stock access.

...more

metal pallet

STO Adjustable pallet racking is probably the most widely used type of pallet racking, and offers free access to every pallet held. It can be built to match the lift height of any fork-lift truck/ Stackers. It consists of upright end frames and pairs of horizontal beams on which the pallets are located, and beam heights are adjustable to suit the height of the pallet loads being stored.In theory, to optimize the use of vertical space, beam heights can be altered if pallet load heights change. In practice, this does not often occur because of the cost and disruption to the operation. Typically, two pallets are stored per bay (ie between rack uprights). The conventional way of laying out APR is to have one row single deep against the wall at each end of the installation, with back-to-back rows in between. This gives every truck aisle access to two rows of racking, and minimizes the number of aisles required. APR is a flexible, versatile storage system, which gives excellent stock access.

...more

Medium Duty Shelving Racks

Shelving is generally made from standard modular components that allow installations of different heights, vertical shelf spacing and shelf depths. The typical standard span width is 1 Ft, 1.5 Ft2 Ft for Medium Duty & 2 Ft to 4 Ft Heavy duty. But long span shelving is also available that facilitates the holding of longer items of stock.This is suitable for light and medium duty work. Mostly used as shelving, adjustable units can be assembled rapidly and adapted to change and expansion. Each shelf can be adjusted independently; used efficiently, this allows the storage space to be used to the full. Most adjustable shelving can be altered without tools. Many companies buy adjustable racking and never use this potential the additional investment must be justified Load/level can be designed upto 500 Kgs for Medium duty racks & Upto 3000 Kgs for Heavy duty racks. Shelving can be accessed in various ways - from ground-floor level, from mezzanine levels (Multi Tier racking).

...more

Heavy Duty Pallet Racks

STO Adjustable pallet racking is probably the most widely used type of pallet racking, and offers free access to every pallet held. It can be built to match the lift height of any fork-lift truck Stackers. It consists of upright end frames and pairs of horizontal beams on which the pallets are located, and beam heights are adjustable to suit the height of the pallet loads being stored.

...more

heavy duty pallet

STO Adjustable pallet racking is probably the most widely used type of pallet racking, and offers free access to every pallet held. It can be built to match the lift height of any fork-lift truck/ Stackers. It consists of upright end frames and pairs of horizontal beams on which the pallets are located, and beam heights are adjustable to suit the height of the pallet loads being stored.In theory, to optimize the use of vertical space, beam heights can be altered if pallet load heights change. In practice, this does not often occur because of the cost and disruption to the operation. Typically, two pallets are stored per bay (ie between rack uprights). The conventional way of laying out APR is to have one row single deep against the wall at each end of the installation, with back-to-back rows in between. This gives every truck aisle access to two rows of racking, and minimizes the number of aisles required. APR is a flexible, versatile storage system, which gives excellent stock access. A boltless, chip-on heavy duty storage systems that are easy in installing and shifting. Custom built for any load, width and height. Ideal for Palletized and Non-Palletized Stores. Cold formed light gauge sections with high strength to weight ration.

...more

Drive Storage System

STO Drive-In Racks allow a lift truck to enter the rack from one side to pick up or pull out pallets. This is done because pallets can slide backwards on a continuous rail. Forklifts drive into the rack to access pallets two or more deep. You are limited in the depth of storage for a particular bay by the size of your facility. Drive-In racks are typically subject to more abuse than selective racks due to the way they are utilized, so rack integrity and strength are important factors. It is ideal rack for cooler or freezer applications. Drive-In & Drive-Through Racks offer the ability to store a large amount of similar loads in a smaller area. Selectivity is sacrificed, but storage density is outstanding. Drive In Racking can store up to 75% more pallets in the same space than selective racking depending on your application. It requires fewer aisles and is better cubic storage.

...more

Cable Trays

In the electrical wiring of buildings, a cable tray system is used to support insulated electric cables used for power distribution and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe. The Ladder Type Cable Trays are contrived with the width ranging from 150mm to 1200 mm & height ranging from 50 mm to 150 mm. The thickness varies from 16 SWG to 10 SWG with all accessories. These trays comprises of two longitudinal side rails connected by individual transverse members called rungs. Accessories : The series of accessories include straight ladder, horizontal elbow, horizontal tee, horizontal cross, horizontal reducer, vertical elbow up, inside, vertical elbow down, outside, coupler plate, fasteners etc. LEGENDS : Straight Ladder Horizontal Elbow Horizontal Tee Horizontal Cross Horizontal Reducer Vertical Elbow Up / Inside Vertical Elbow Down / Outside Coupler Plate Perforated Cable Trays : Our range of perforated or ventilated trays is offered in drilled and perforated channels. Available in 50 mm lengthwise and a minimum of 25 mm crosswise, the perforated type cable trays are available at widths from 50 mm to 900 mm and are designed for standard support span of 2,500 mm. The perforated type cable trays are made of HR sheets and also from pre galvanised sheets with various thickness and flange heights. Race Ways : Our raceways offer perfect solutions for wiring management systems. Contemporarily designed and affordable, the raceways are functional for wire enclosure applications in commercial, industrial and residential environments. Materials used : Common cable trays are made of galvanized steelstainless steel, aluminum, or glass-fiber reinforced plastic. The material for a given application is chosen based on the corrosion resistance required for the location.

Length : Standard length of tray is 2500mm

...more

Easy Open Ends

Be first to Rate

Rate ThisOpening Hours