CNC Milling Tools

Get Price Quote

Tooling comes in different sizes: NMTB-25, 30, 35, 40, 45, 50 and 60. NMTB-25 is the smallest, used on small machines, while NMTB-60 is the largest. For a single taper type, the different sizes are scaled versions of the same basic shape.

Mtw Milling Machine

Get Price Quote

This MTW series milling machine is designed by our experts, according to collected advices from customers’ long-term experiences. It takes the most advanced patent technology from European and the supply the customers with outstanding performance at low costs. Features Cone gear whole transmission-compact conformation, convenient installation, reducing dissipation of energy. Optimization design for grinding roller grinding ring of main-spring pressurization, high-wearing feature. High-performance powder concentrator design-accurate and quick selection of powder. Unique wear proof perching knife design- fission type, convenient for maintenance, wear resistant material, long life. Application The MTW series milling machine is ideal machine for grinding barite, limestone, mica, talcum, quartz, calcite, granite, porcelain clay, basalt, gypsum, gold, iron ore, bauxite, copper, cement, coal etc. So it has wide application in powder making industry of construction, mining and paper-making and so on.

Best Deals from Milling Machine

Milling Machine Tools

Get Price Quote

Milling Machine Tools, Gear Shapers, Mud Agitators, Carbide Tipped Drill

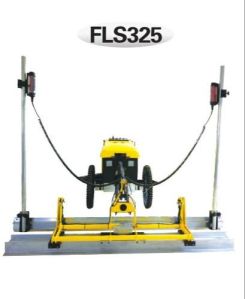

Concrete Laser Screed

Get Price Quote

Universal Milling Machine

Get Price Quote

Mill Duty Motors

Get Price Quote

SS Tube Mill Machine

Get Price Quote

Minox offers stainless steel pipes, tubes (seamless and welded), rods and suitable fittings in various grades and excellent finish which are extensively used in applications like architectural building construction, interiors, parmaceutical, food and dairy etc.

Vibratory Impacting Rammer

Get Price Quote

High Frequency Milling Spindles

Get Price Quote

Vertical Mill

Get Price Quote

LM series vertical mill is one advanced mill, adopting top technology domestic and abroad, and based on many years’ mill experiences. It can crush, dry, grind, and classify the materials.LM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, chemical industry, non-metallic mineral. It is used to grind granular and powdered materials into powder with required fineness. Features 1. Low Investment Cost.This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system. In addition, it can be installed outside, so it will reduce a large number of investment costs.2. Low Operation Cost. ⑴ High efficiency: roller compacted materials directly onto the grinding disc, so power consumption is low. Compared with ball mill, it saves energy consumption by 30% ~ 40%.⑵ Less wear and tear: As the roller is not in direct contact with the disc, and material of the roller and liner is high quality, so life lime is long.3. High Drying Ability.As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with different humidity.4. Simple and reliable operation.⑴ It is equipped with automatic control systems, so remote control makes it easy to operate. ⑵ It is equipped with one device,which prevents the roller from contacting with the liner directly, and avoids the destructive impact and severe vibration.5. The stability of product quality. As the material stays in the mill for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.6. Maintenance convenience.By repairing fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime loss.7. Environmental protection.It is with small vibration, low noise, and the overall sealing. The system works under negative pressure, Working Principle Vertical mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds. There are two circular disc slot, and roller to the tire shape, work pressure in the tank. Disc roller and the relative sliding velocity between small and roller can swing, even if the roller sleeve and the disc after the liner wear can guarantee a good abrasive, will not affect the grinding effect. Roller symmetrical structure, one side can be upside down after use and wear. Material grinding process: hydraulic pneumatic roller device through the pressure applied to the material on the crushing of materials, the materials have been moved to crush the edge of disc, from the disc around the nozzle from the exhaust air to improve these materials to Separator.Meal to separate returns after a concentrated mill, fine powder was collected in the precipitator unloading. In the gas flow is small, the meal can not be increased to enhance air flow, they would fall through the nozzle discharged outside the mill, bucket elevator to be transported to the feeder of vertical mill and was re-grinding mill feed people.This cycle features of the way there:ring by adjusting the air valve, can change the product fineness can shide mill bed load material uniformity and stability, improving the grinding efficiency; coarse particles in the external circulation, helps reduce Fan power consumption and overall system power. Processed Materials : Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, iron ore, quartz, active carbon, carbon black, ceramic, clinker, ect. Applications : Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Excavator

Get Price Quote

Excavator

Milling Machinery

Get Price Quote

Milling Machinery, Socket Grinder, Flexible Shaft Grinder, Pneumatic Tools

Rotary Tables

Get Price Quote

Rotary Tables, Drilling Machines, Gears, Planetary Gear Boxes

Scheiss Milling Machines

Get Price Quote

We are offering scheiss milling machines. vertical turning and milling machines gantry milling machines

CNC Milling Machine

Get Price Quote

CNC Milling Machine, CNC Tools, Adaptors, Electric Paint Sprayers

CNC Milling Machine

Get Price Quote

CNC Milling Machine, CNC Lathe Machine, CNC Vertical Lathe Machine

Heavy Duty Precision Vertical Turret Milling Machine

Get Price Quote

Heavy Duty Precision Vertical Turret Milling Machine

CNC Milling Machines

Get Price Quote

CNC Milling Machines, CNC Grinding Machines, CNC Vertical Machines

Mill Duty Motors

Get Price Quote

Mill Duty Motors, LT Switchgears, Motor Control Center, Motor Controllers

Excavation Equipment

Get Price Quote

We are offering excavation equipment. Any brand drill rigs, construction machine, compressor, trucks, man ,caterpillar, drill bits, top hammer, dth hammer, oem spares part, surgical equipment, watches, corporate gifts etc etc

Bed Type Milling Machine

Get Price Quote

Bed Type Milling Machine, Cold Shearing Machine

Anti Vibration Milling Tools

Get Price Quote

Anti Vibration Milling Tools, Extra Long Drills

Excavator

Get Price Quote

Excavator, Caterpillar, Earth Moving Spare Parts, Engine Stop Cable

Milling Machines

Get Price Quote

Milling Machines, Machine Building Equipment, Universal Milling Machine

Excavators

Get Price Quote

Excavators, Construction Machinery Parts, Earthmoving Spare Parts

CNC Milling

Get Price Quote

CNC Milling, Turning, Cam Programing Service

Hydraulic Excavator

Get Price Quote

Hydraulic Excavator, Rock Breaker Chisel, Pneumatic Grease Gun, Jcb Bucket

Turret Milling Machine

Get Price Quote

Turret Milling Machine, Steel Bar Bending Machine, Simple Sucker Cup

Surface Grinders

Get Price Quote

Surface Grinders, Band Saws, Radial Drill Machine, Industrial Machinery

CNC Universal Milling Machine

Get Price Quote

CNC Universal Milling Machine, CNC Machinery, CNC Lathe Machine