Plastic Blow Moulding Machine

Get Price Quote

The Plastic Blow Moulding Machine has controlled extruder output. The compact size of the machine is an advantage for the small units. We offer Plastic Blow Moulding Machine with single and double station configurations for single and multiple die heads that enable production of a wide range of containers. We have developed expertise in designing, manufacturing, supplying of Auxiliary Equipment & Moulds. We also offer to prepare entire project, develop blow moulding machine, outsource the ancillaries, and commission the project at your site. We also offer Double Color Blow Molding Machines that are used in the manufacturing process of toys, balls, parts for toys, view strip containers, etc. Features Hydraulic clamping and shooting unitAC Variable Speed DrivesSingle and multiple headsLow Operational CostSuitable for Mass ProductionComplete PLC Control Programme Used For Manufacturing Pharmaceutical & Cosmetic bottlesContainers for paint, milk, gum, ink, engine oil etc

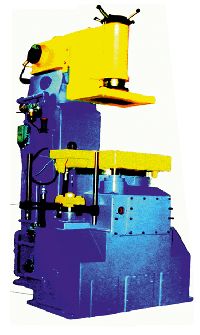

Rubber Molding Press

Get Price Quote

Features: Speed Tonnage Single or multi step forming Variable speed or tonnage during pressing Our organization brings forth for our customers a reliable range of rubber molding press. To cater to the variegated application requirements of clients, we make these machines available in various technical specifications. Owing to these machines' compliance with international standards, these are widely used in engineering related industries. Suppliers in Ahmadabad rubber molding press.

Best Deals from Molding Machine

Hydraulic Rubber Molding Press Machine

500,000 - 700,000 Per Unit

1 Unit (MOQ)

Cryogenic Deflashing Machine

Get Price Quote

Stretch Blow Molding Machine

Get Price Quote

1 Piece (MOQ)

Mould Oiling Machine

Get Price Quote

Mould oiling machine offered by us is made available by us in working capacity of up to 1800 pocketshr and 500-750pockets ltr options with electric load of 500w 1p. Further, these can effectively handle pneumatic loads of 120kgcm2 or 5 bar minimum with manpower requirement of 1 or 2 which is actually based on said delivery system. Here, the system is also offered with solenoid valve rating of 2 bar to 12 bars. Features: our mould oiling machine posses following unique features: long operational life reliable operation standards low maintenance requirements sturdy finish

jsw injection molding machine

1,300,000 Per Bag

Model: It’s mentioned below the Picture. Condition of Machinery –Good & running condition. Make- 2019 Original Price- Rs. 17,84,042/- Expected Price- Can be negotiated once the machinery is finalized. Model:

Pvc Paver Mould

Get Price Quote

Plastic paver molds with good quality of plastic and recyclable meterial used 3.2 peaces per square feet.

PBX Moulding Press

Get Price Quote

Blow molds manufacturer

64,000 Per Set

Zig zag paver molds with high quality and finish easy demolding very durable ,we have lines and other designs we also do customised design available in three sizes 40 60,80 ,120 mm in thickness

Strap Mould Battery Making Machine

30,000 - 38,000 Per Piece

1 Piece (MOQ)

Molding Machine

Get Price Quote

Manufacturer of Jolt Squeeze Molding machine of BMD-300, BMD-450 & BMB-900 Sturdy construction Short cycle time for high productivity High dynamic squeeze pressure Centralised auto-lubrication

Chocolate Moulding Line

Get Price Quote

A.M.P Rose chocolate moulding lines have been designed with the chocolate manufacturer in mind – high quality precision engineered assemblies have been developed through years of experience in the chocolate manufacturing industry. With the focus on reliability, reduced maintenance, cleaning and downtime these lines ensure high efficiency rates even on 24/7 production. The chocolate moulding line is constructed in modules, making the line extremely flexible and allowing for future expansion, or the addition of further modules such as nut or biscuit placing. Synchronously matched Servo motors are used to drive the chains on a continuous basis, thereby ensuring smooth mould flow throughout the plant. Motor torque settings are monitored and if overloaded will stop the plant in the event of a problem. The moulds used have centre pin mounts on continuously moving chains, which ensures smooth mould transition throughout the plant and reduces breakages to a minimum. Mould presence and mould pin detection sensors are also provided. A Servo motor moves the Depositor in a linear motion at exactly the same speed as the mould chains, which eliminates intermittent motions and allows for high speed depositing cycles on the chocolate moulding line.The drives to the Right and Left side Depositor pistons are also via Servo motors, providing excellent control and flexibility. The Depositor can be set for spot or ribbon deposits, ensuring clean and accurate moulding , whilst maximising line speed and minimising moving parts.‘One-shot’ products can be made on the depositor, typically at up to 60% filling rates. Centres such as caramel, praline, fondant, crème and jelly can all be used. The Depositor has been designed for quick product change-overs. Most products can be changed through the HMI and with suitable nozzle plates. The HMI stores the pre-set recipes and they can be recalled at the touch of a button. Where change from one piston block to another is necessary, an optional ‘quick release’ block can be provided. The depositor is mounted at a height that is convenient for the operator to monitor all functions from ground level. The 60mm thick insulated doors are clad in food-grade stainless steel are therefore hygienic and easy to clean and at the same time reducing plant noise to a minimum. These doors provide complete insulation, thereby ensuring that the correct cooling profile is maintained across the full length of the plant. The doors are hinged to allow access from both sides, and panels have windows and interior lighting where inspection is necessary. All these special features combine to ensure that products made on A.M.P Rose moulding lines are of the best quality, with perfect shapes and with high gloss and smooth surface finishes. Optional Modules Specifications & CapacitiesThe A.M.P Rose chocolate moulding line can be made to produce all kinds of chocolate slabs and articles, for example with fruit or nut inclusions, or with wafer or biscuit inside. Due to their modular design these lines can also be extended at a later date, either to increase capacity or to add specific modules. For whole or chopped nuts for example an additional nut/chocolate mixer could be added as a simple retro-fit. Whole Nuts – A nut feeding system can be supplied to feed whole nuts into the mould cavities.Inclusions – Chopped nuts, rice crisp pieces, raisins and other fruit pieces can be incorporated into the chocolate prior to depositing.Chocolate with Biscuit – A biscuit placing system can provide a new product range.Chocolate with wafer sticks – A cut and place module for wafer sticks/books can be incorporated into the moulding line.Aerated Chocolate – Add texture whilst giving away less product with the addition of an aerated chocolate depositor. OUTPUT Up to 20 moulds/minute 400 – 2,800 kg/hr MOULD SIZE 622 x 233 x 34mmand 922 x 233 x 34mm

Rubber Moulding Press

Get Price Quote

Rubber Injection Moulding Press or commonly known as Injection Moulding press are of great use to execute industrial production of bulk products. These presses are manufactured with superior injection unit FIFO, keeping in mind the quality of the end products. These innovative machines employ two-stage material supply for greater precision. The system feeds and inject raw material in a way that there is no wastage. Rubber Injection Moulding presses is perfectly suitable for moulding products with simple to the most complex geometry.The Rubber Injection Moulding Press process combines an extruder, which heats and fluxes the rubber with the help of reservoir & mould. While the rubber mold is curing, fresh rubber is prepared for the next cycle. This semi-automatic process saves the valuable time and energy. The compounds used for injection moulding are optimized. They smoothly flow through the nozzle & runner system and fill the mould under controlled pressure. The materials to be injected do not cure in the process, but curing is quick once it enters the mould.

bakelite molding machine

Get Price Quote

Manufacturer & Exporter of Bakelite Moulding machine & Bakelite Molding Machine. Our product range also comprises of Press Machines, Hydarulic cylinder and Hydro Pneumatic Sheet Metal Riveting Press. We are engaged in manufacturing and supply of hydraulic and Hydro Pneumatic Bakelite molding machines up to 150 Tonne with Heaters and Controllers, we also make modified solutions on customer request for special application.

Industrial Injection Molding Machine

Get Price Quote

Download the PDF to get the Specification of Injection Molding Machine (Demand Machinery Taiwan). The assortment of Industrial Injection Molding Machines is equipped with five-point toggle mechanism and differential hydraulic circuit in order to substantially accelerate forming speed. It also increase forming rate and reduce cycle time of production. The ejecting, injection and clamping units of these machines use linear transducers to control movement stroke of each function in a precise manner. Multiple pressures, speed, time and position controls of machinery performances aim for power savings and achieving accuracy in finished articles. Usage of double injection cylinder is to shorten injection stroke as well as to avoid material leakage CE series controller contains several interfaces of mechanical functions that are easy to run by operators Advanced mechanical applications such as power-saving variable pump, closed-loop hydraulic circuit, double (triple) independent hydraulic circuits and high-speed injection, accumulator injection etc. are able to be installed on B series, to satisfy the demand of higher production and lower cost from

Moulding Brushing Machines

Get Price Quote

Features The POINT to POINT through feed machining line has revolutionized the field of boring, grooving and routing thanks to its innovative technology and maximum flexibility and productivity This series has been designed to obtain the maximum flexibility possible while maintaining a high volume output. No machine setup time therefore greatly increased part to part throughput and overall productivity. Exclusive optical part reading for perfect ede referencing and boring without depending on the operator's accuracy Fully automatic parts positioning by the machine therefore operator misfeeds are no longer an issue. Small batch random part processing is an effective as large run processing. 4NC axis control including U, Y, Z and X (micro head movement for front/back horizontal boring and routing).

Curb Packing

Get Price Quote

We offer curb packing. Everyone loves a well landscaped lawn and no landscaping is complete without curbing. Granite curbstones is the most popular choice for curbing due to its durability. Curbstones serve a number of purposes: • retains the carriageway edge • prevents loss of structural integrity • acts as a barrier between road traffic, pedestrians or verges • forms a channel from which surface water can drain away • pallet packing & crate. We are offering a wide range of curbs at reasonable prices as we being the direct manufacturer, exporter and supplier of various granite products. customised sizes, thicknesses and finishes available on request.

Reverse Tilting Permanent Mold Casting Machine

Get Price Quote

Low maintenance due to few moving parts, heavy duty, rugged, and dependable. Unique design allows the mold to be poured while the parting line is perpendicular to the floor. The Machine tilts the mold so that the parting line is parallel to the floor for solidification and ejection. Cushioned tilt cylinder provides a smooth tilting motion from start to stop. Twin ram cylinders provide a safety factor, as well as extra holding pressure and better clamping balance. Integral lower eject is included.

Candle Molding Machine

500,000 Per unit