Drying Oven

Get Price Quote

Features : Stainless steel inner chamber; foursquare semicircle transition; flexible positioning andremovable shelf, air duct lateral plate and bottom heater covering are easy assembly anddisassembly for convenient cleaning Micro-computer high-brightness digital or liquid crystal temperature controller, which hasfunctions of timing and over-temperature protection Adjustable fan speed; set blowing rate as needs to meet the multiple requirements ofexperiment Independent temperature safety device; auto alarm and heating suspend when maincontroller fails to work, which provide double protection to ensure experiment run safelyand no accident would happen Door with wide double-glass observation window, adjustable air-tight buckle lock andsilicon rubber seal which efficiently prevent heat loss BE Type has the following characteristics other than the above function: With adjustor to adjust the fan speed, the user can choose to use the fan, and adjust the speed to ensure hightemperature evenness, or not use the fan to avoid the powder or other small samples moving the inner chamber Large LCD screen shows the multiple data, has the function of timing and over-temperature protection Independent audible and visible temperature-limiting alarm system, cut off the power automatically when overtemperature limit, ensures experiments run safely and no accident would happen

Hot Air Oven

Get Price Quote

We are a reputed Manufacturer and Supplier of Hot Air Oven from Bangalore, Karnataka. Laboratory Hot Air Oven provided by us is widely appreciated for its excellent design and efficient performance. We offer customers the option to customize their order of Hot Air Oven according to their specifications. We are capable of delivering bulk quantities of Hot Air Oven to our clients all over the country. Optional : Safety blind Controller Air Circulating Fan Stainless Steel Perforated Trays Digital Timer Chamber Validation/ calibration Imported Microprocessor based PID Controller Digital Microprocessor based controller with RS-232 & PC inter phase Any other sizes can be supplied on demand Higher temperature accuracy models can be supplied on demand Fully Stainless steel model available on demand.

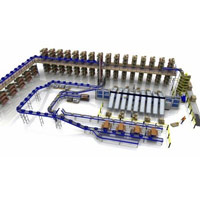

Best Deals from Overhead Conveyor Ovens

Rotary Rack Oven

Get Price Quote

1 Piece (MOQ)

MS Powder Coating Oven

500,000 Per Unit

Drying Oven

Get Price Quote

* external material: cold-rolled steel with anti-bacteria powder coating. * stainless steel inner chamber, round angle structure, adjustable shelves. * pid control with led display, soft touch operational key, timing function and over-temperature protection. * door with double-layer tempered glass observation window, adjustable air-tight buckle lock, and silicon rubber seal, which provide good seal ability and efficiently prevent heat loss.

Electric Industrial Oven

480,000 Per Units

Pizza Oven

10,000 Per Piece

1 Piece (MOQ)

Vacuum Drying Oven

120,000 Per Piece

Gas Oven

Get Price Quote

Conveyor Ovens

200,000 - 2,500,000 Per unit

1 unit (MOQ)

Electric Powder Coating Oven

210,000 Per Piece

Semi Automatic Batch Reflow Oven

500,000 Per Piece

Hot Air Oven

5,000 Per Piece

Our Ovens have been designed for high performance drying, thermal process with fresh air supply, short process application, heat-up time and with precise heat control. Compliance as per ASTM , ISO, IS STANDARD FEATURES Chamber Design : Double / Triple Walled Inner Chamber : Made of thick Gauge, Stainless Steel 304. Finish : Matt finish. Outer Body : CR/Mildsteel sheet. Powder coated finish or S.S. Matt finish Controller : Microprocessor based Digital PID controller with both process and set value display. Sensor Type : RTD sensor. Trays : Adjustable Rod mesh or Perforated Trays. Air Circulation : Conventional Air flow by dynamically balanced SS blower with Heavy, continuous Duty TEFC motor. Insulation : Low ‘K’ factor Thick Ceramic Wool/Glass wool Insulation Heaters : Special SS air heaters. Gasket : Silicone Gasket. Temp. Range : 50°C to 200°C : 50°C to 250°C : 50°C to 300°C : 50°C to 400°C Resolution : 0.1 / 1°C Accuracy : ± 1°C @ 100°C Operation : 230V 50Hz, single phase. MODELS : A) Economy B) Standard C) Laminar (ISO oven) D) Geared E) Industrial F) Thin Film Oven OPTIONAL ACCESSORIES & FEATURES : 1) Toughned Glass ViewWindow 2) Digital Timer 3) High Set point cutoff 4) Door to blower & heater Interlock 5) Temperature logger with pc interface 6) Profiling control 7) Cooling Coil 8) Air Curtain (For Industrial Ovens) 9) Spare Trays (Rod mesh/Perforated) 10) Variable Air Flow Rate 11) Touch screen PLC based control with inbuilt data and event logging for totally integrated test process 12)Motorised Turn table for sample rotation (RPM & Load capacity as per requirement) 13)Door Locking Arrangement 14) Castors for easy movement 15) 110V single phase/440V Three phase

X-ray Film Drying Oven

1 Per Box

1 Box (MOQ)

Features it’s used to dry the x-ray film quickly in the radiology department of medical institutions. * microprocessor pid temperature control with led display. * polished stainless steel chamber. * multi-layer hollow tempered glass window, safe and reliable. * forced air convection by high resistance fan. Model bov-xf124 capacity 124 l loading capacity 18 films temp. Range rt+5~70°c temp. Fluctuation ≤1°c temp. Resolution ±2°c power consumption 1215 w power supply 220v±10%,5060hz internal size(w*d*h)mm 590×370×570 external size(w*d*h)mm 640×500×940 packing size (w*d*h)mm 770×630×1100 gross weight(kg) 115

Drying Oven

22,000 Per Piece

1 Piece(s) (MOQ)

Over the years, our organization has a carved a niche for itself in Bangalore(India) and is dedicated towards becoming a trustworthy trader in other markets as well. With the assistance of our safe and automatic warehousing system, we are able to store the entire lot of products in a secured manner. The entire lot is cross checked at regular basis for ensuring complete safety of the products.

Hot Air Oven

Get Price Quote

This product is equipped with digital temperature indicating controllers with a suitable sensor for precise temperature control. Offered range is manufactured using modern machinery under the supervision of highly qualified professionals, to ensure high standards of quality and efficiency.

vacuum components

Get Price Quote

Vacuum components must live up to high standards.Vacuum vacuum components meet the high quality standards that are placed on vacuum components. The vacuum components are helium leak-tested and show leakage rates better than 10-10 Pa. m3s for ISO-KF, ISO-KISO-F flanges and 10-11 Pa.

Hot Air Oven

Get Price Quote

We are offering hot air oven. a complete cycle involves heating the oven to the required temperature, maintaining that temperature for the proper time interval for that temperature, turning the machine off and cooling the articles in the closed oven till they reach room temperature.

Pizza Oven

Get Price Quote

We are offering our clients with the high performing Pizza Oven. Based on advanced technology, Electric Pizza Oven efficiently prepares pizza within minimal time frame. Pizza Baking Oven is manufactured by making use of quality checked raw material as per the industry standards and norms. Along with this, our clients can avail Portable Pizza Oven in different technical specifications as per their requirement. Features Standard designs Low power consuming Good quality materials are used Specifications Power : 2000w Voltage : 220v

Convection Ovens

Get Price Quote

JSOF-Series Forced Convection Ovens utilize a motorized fan to force air circulates across heating element to supply hot air into the chamber. The fan allows more consistent temperature distribution of the chamber for applications in which good temperature uniformity or faster heat up and short drying time are needed. JSOF-Series Natural Convection Ovens heat up chamber with mild gravity air convection with heating element located under the chamber. Ideal for general and conventional laboratory drying purpose

Industrial Ovens

Get Price Quote

We manufacture wide range of industrial ovens with robust construction designed for high efficiency, meeting customer needs suiting to the applications. We manufacture our Industrial ovens with modern manufacturing machines, which deliver an output product that matches to international standards. These Industrial ovens are highly durable and reliable product. We manufacture electrical gas fired of both batch continuous type.

Vacuum Drying Oven

Get Price Quote

Because of its diversity of needs, HHV has been designing and manufacturing variety of vacuum drying oven suits customer specific applications. These vacuum drying ovens are being used to achieve rapid drying at low temperature, including the drying of deep pores, in a way that does not damage the products. In these vacuum drying ovens, the dried material is exposed to a vacuum, thus reducing the boiling point and leading to water evaporation even at low temperatures. Drying usually refers to the removal of liquids from a subject via evaporation or vaporization. In drying processes that use convection, the vapour pressure of liquid that is to be expelled at a certain temperature or pressure is critical. If the vapour pressure is identical to or less than the liquid content in the atmosphere, no drying is possible.

Rotary Oven

Get Price Quote

Rotary oven offered is backed by latest process technology support and delivers superior process values in given bakery applications. The oven specifications comprise dimensions of (in mm - external) 3020(w) x 2250(d) x 2400(h) mm 119”(w) x 89”(d) x 95”(h) with minimum oven dimensions of (h x w) 2500(h) x 1350(w)mm 100” x 53”. The other operating specifications include maximum temperature of 300 °c, connected load of 4.5 kw (6.2 hp) (415 vac, 50 hz) and weight of 3000 kg. Having tray size of 450 mm x 700 mm (18” x 27”), the per batch working capacity of bakery oven b-1800 comprise bread (400 gm - 672 loaves 4 trolleys x 14 shelves), sponge cake (212 kg - 4 trolleys, 56 trays), buns (45 gm 1728 nos. - 4 trolleys, 72 trays), biscuits (80 kg - 4 trolleys, 72 trays), dry rusk (72 kg - 4 trolleys, 72 trays) and khari (48 kg - 4 trolleys, 72 trays). With the baking equipment taking minimum of the work spaces, these also come fitted with steam system that helps in providing high volume as well as excellent baking quality of all products in term of shine, texture and crust provided in the baked delicacies. Here, these are also made available in a variety of models so as to befit baking process requirements of different clients.

Industrial Ovens

Get Price Quote

Heatcon ovens upto 450 degree centigrade is used in the below applications:- Laboratories, plastics, cables, electroplating, hardware, optoelectronics, plastic products, molds, shoe materials, powder coating, printing, medical, scientific research units, colleges and universities, mining, aerospace and research institutions. Features :- Ceramic/glass wool insulation, high thermal efficiency, low heat loss and long life. The air circulation with special shaft motor device achieves excellent temperature uniformity. Trays and ports to temperature measurements can be customized. Intelligent program temperature controller, which is available to edit and save the multi-segment program. Data loggers with PC interface. OUR OTHER INDUSTRIAL OVENS:- Rapid quench oven Batch oven-drawer type oven Conveyor oven Batch oven-drawer oven Top loading oven Lab oven Front loading oven

Hot Air Oven

Get Price Quote

Hot air ovens are electrical devices which use dry heat to sterilize. They were originally developed by Pasteur. It consolidates a heating system with fine air stream making uniform temperature because of characteristic convection inside of the chamber. The hot air with fumes and dampness streams out through a controlled ventilation system. In a perfect world utilized for preheating, sterilizing, drying, backing, aging etc. Usage: A complete cycle involves heating the oven to the required temperature, maintaining that temperature for the proper time interval for that temperature, turning the machine off and cooling the articles in the closed oven till they reach room temperature. The standard settings for a hot air oven are: 1.5 to 2 hours at 160 °C (320 °F) 6 to 12 minutes at 190 °C (374 °F) Polymer Modified Water based Rubberised Elastomeric Bitumen gel for Waterproofing and Protective Coa ....plus the time required to preheat the chamber before beginning the sterilization cycle. If the door is opened before time, heat escapes and the process becomes incomplete. Thus the cycle must be properly repeated all over. These are widely used to sterilize articles that can withstand high temperatures and not get burnt, like glassware and powders. Linen gets burnt and surgical sharps lose their sharpness.

Microwave Oven

4,000 Per Piece

Drying Ovens

35,000 Per Piece

Prices varies with models external material, cold rolled steel with anti bacteria coating. Stainless steel inner chamber, round angle structure, adjustable shelves. Pid control with lcd display, soft touch operational key , timing function and over temperature protection.

Vacuum Ovens

50,000 - 100,000 Per

1 Box (MOQ)

Vacuum Oven

Get Price Quote

We are offering Lab Vacuum Ovens Catalog , Furnaces, Ovens, Vacuum oven VO - Heating drying ovens, Vacuum Ovens, Vacuum Furnaces, Vacuum drying chambers Dry samples without residue, scaling or oxidation, and all in a gentle cycle. The two models of vacuum ovens from BINDER with their proven technological features excellently address the strict requirements of industrial and scientific laboratories. Samples and similar materials incorporating flammable and non-flammable solvents can be dried, depending on the individual use. The vacuum ovens use a unique safety design that, together with accustomed outstanding performance, sets the bar in terms of quality and safety

Heating Oven

Get Price Quote

Heating oven Trolley Machinery. Moreover, we employ high grade raw materials to manufacture these products as per the latest market trends. Clients can avail these machines from us at affordable prices.