Pre Engineered Building Systems

Get Price Quote

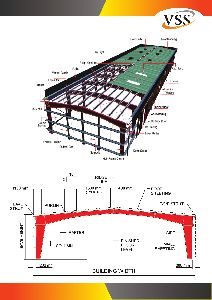

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures. Built-up sections are fabricated at the factory to exact size, transported to site and assembled there with bolted connections. This type of Structural Concept is generally used to build Industrial Buildings; like –Railway / Metro Stations, Warehouses etc. The adoptability of PEB in place of Conventional Steel Building design concept resulted in many advantages, including economy & easier fabrication. These building structures can be finished internally to serve any functions i.e., actually help in low rise building design. Examples of PEB Buildings are warehouses, Canopies, Factories, Bridges etc. Components of PEB : Pre Engineered Buildings consist different steel structural members which are: Primary Frames Secondary Structural Elements: Cold Formed Members, which can be in different shapes like “Z”, “C” etc. In general known as “Purlins”. Roof & Wall Panels : Tin shades & Curtain Wall made of Glass & Roll-formed steel sheets usually comes in this category Sandwich Panels: Sandwich Panel is made of three layers, in which a non-Aluminum Core is inserted between two aluminum sheets. Other Accessories: Bolts, Insulation, etc. Advantages of PEB : There are many advantages of Pre Engineered Buildings, which are as follows, Quality control is the main advantage as all the structural member are engineered beforehand, standards of different codes also taken into consideration & these components are made in factory under the supervision of Quality Control Engineer. Lower cost due to the saving in design, manufacturing and on site erection cost. Minimizing time of construction due to the use of software for design of the structural components. Low Maintenance due to use of standard quality of paints over steel members , which increases the ability to withstand & finally the maintenance cost will be low as compare to conventional steel building. Quick Erection, as all the members are Pre Manufactured & skilled labor is used for connections of different components. Warranty on PEB, mostly warranty period of 20 years given by manufactures for PEB. Disadvantages of PEB : Although PEB have many advantages in the field of Industrial structure but still there are some demerits of Pre Engineered Buildings, which are as follows, Rusting / Corrosion Sensitive, as if the quality of steel used or paint used for coating of steel members is not of good quality , then it can damage the structure and thus reduces the life of structure. Insulation Cost, as insulating the building to an agreeable benchmark will furthermore add to your construction costs. Appearance, Steel Sections can be unattractive when left exposed.

Pre Engineered Buildings

Get Price Quote

We are offering pre engineered buildings. Pre engineered buildings offer the advantages of light structure and speedy construction. Our design cell designs the structure to your requirement.

Best Deals from Prefabricated Building

pre engineered building structure

100,000 - 10,000,000 Per Square Feet

1 Square Feet (MOQ)

Pre Engineered Buildings

Get Price Quote

Astal Interbuild Pvt Ltd are into Pre Engineered Buildig Manufacturing since last 11 years and completed ennumber of projects. About 5,00,00 sqft projects are now under construction. We undertake, all type of pre fabrication, Pre engineering for Industrial warehouse, Factory shed, Re roofing , Commercial complext etc. at qualitative and cost effective method.

Prefabricated Steel Buildings

100 - 100 Per kg

PEB roofing system

Get Price Quote

Specialist with 28 years' experience in Design, fabrication and erection of PEB structures, Tower Connecting Bridges, Railway bridges, Mezzanine floor Structures, Roofing structures, Solar Panel Mounting Structures, Customized Office interior cabins and compartment installment and Heavy Structural Fabrications.

Pre Engineered Steel Buildings

Get Price Quote

We are engaged in design, manufacture, fabrication, supply and installation of pre-engineered steel buildings conforming with international quality standards. Every steel building is designed to meet specific customers requirement viz subjective loadings, size, project location for rain, wind, snow and seismic coding. We have the expertise, creativity and dynamic leadership with substantial experience in the field of structural engineering and steel. With access to state of art technology, meticulous planning and execution, following best practices in business, we assure our customers of processing and executing their orders to their utmost satisfaction, in time & every time.

Steel Structure (PEB)

Get Price Quote

Concrete filled steel column (CFSC) The CFSC system has many advantages compared with the ordinary steel or the reinforced concrete system. One of the main advantages is the interaction between the steel column and concrete, local buckling of the steel column is delayed by the restraint of the concrete and the strength of concrete is increased by the confining effect of the steel column. Advantages The CFSC column system has many advantages compared with ordinary steel or reinforced concrete systems. Interaction between steel column and concrete: Local buckling of the steel column is delayed and the strength deterioration after the local buckling is moderated, both due to the restraining effect of the concrete. On the other hand, the strength of the concrete is increased due to the confining effect provided by the steel column. Drying shrinkage and creep of the concrete are much smaller than in ordinary reinforced concrete. Cross-sectional properties The steel ratio in the CFSC cross section is much large than in reinforced concrete and concrete-encased steel cross sections. The steel of the CFSC section is well plasticized under bending because it is located most outside the section. Construction efficiency Labor for forms and reinforcing bars is omitted, and concrete casting is done by tremie or pump-up method. This efficiency leads to a cleaner construction site and a reduction in manpower, construction cost, and project length. Fire resistance Concrete improves fire resistance so that fireproof material can be reduced or omitted. Cost performance Because of the merits listed above, better cost performance is obtained by replacing a steel structure with a CFSC structure. Ecology The environmental burden can be reduced by omitting the form work and by reusing steel column and using –quality concrete with recycled aggregates. 1. The concrete filled column system has many advantages compared with ordinary steel or reinforced concrete systems. The main advantages are listed below: 2. Interaction between steel tube and concrete: Local buckling of the steel tube is delayed, and the strength deterioration after the local buckling is moderated, both due to the restraining effect of the concrete. On the other hand, the strength of the concrete is increased due to the confining effect provided by the steel tube, and the strength deterioration is not very severe, because concrete spalling is prevented by the tube. Drying shrinkage and creep of the concrete are much smaller than in ordinary reinforced concrete. 3.Cross-sectional properties: The steel ratio in the CFST cross section is much larger than in reinforced concrete and concrete-encased steel cross sections. The steel of the CFST section is well plastified under bending because it is located most outside the section. 4. Construction efficiency: Labor for forms and reinforcing bars is omitted, and concrete casting is done by Tremie tube or the pump-up method. This efficiency leads to a cleaner construction site and a reduction in manpower, construction cost, and project length. 5. Compared with the hollow steel sections, concrete filled steel sections will have a higher fire resistance, and the need less fire proof material around the steel tubes, because concrete has a larger thermal capacity than air which is enclosed in the hollow steel tubes. Even if the sustained loads carried by steel are decreased by heat, the column will not be crushed during the fire if the columns are designed to sustain the dead and live loads only by their concrete cores. So the structures will not surer great damage. Concrete improves fire resistance so that fire proof can be omitted interaction b/w steel tube and concrete: Local buckling of the steel tube is delayed, and the strength deterioration after the local buckling is moderated, both due to the restraining effect of the concrete. 6. Significant economic advantages over either pure structural steel or reinforced concrete alternatives. 7.Identical cross sections with different load and moment resistances can be produced by varying steel thickness, the concrete strength and reinforcement. This allows the outer dimensions of a column to be held constant over a number of floors in a building, thus simplifying the construction and architectural detailing. 8. Higher strength and stiffness compared with RC columns of the same materials properties. Cross section properties: Steel ratio into CFST is much larger than in RC sections. The steel of CFST sections is well plastified under bending because it is located most outside the sections. 9. Cost performance: Cost effective when we compared to steel structure because of composite effect (steel and concrete). 10.Environmental: Form work can be reduced so that production of steel will be less and using high quality concrete with recycled aggregates.

Prefabricated Building

Get Price Quote

We have emerged as a reliable Manufacturer and Supplier of the Prefabricated Buildings. Our Prefabricated Buildings are eco-friendly and easy to assemble. Pre-fab portable & non-portable buildings are structurally designed & factory engineered to match for permanent standard. We manufacture these Prefabricated Buildings as per the requirement of the clients. Moreover, owing to the sprawling infrastructure, we are ready to take up bulk consignments of the customers as per their requirement. Advantages Prefabricated homes can be ordered and transported straight to your block. You can organize the stumping and plumbing and electrical connections or have it pre ordered into the overall package.Prefabricated homes cause less damage to the environment than conventional brick homes. They can be mass produced or fabricated to your design and are quick to build so it will save you rent as brick homes tend to be dragged out with different contractors� being involved.They will cost a lot less, than a double brick home by far. They can be insulated to reduce the cost of heating and cooling. Besides, our Prefabricated Buildings are fabricated in such a way that these can be redesigned and shifted as per the requirement.

Pre Engineered Buildings

Get Price Quote

Pre Engineered Buildings (Production Applications & Process Lines) HalleysBlue Steel Buildings are much suited for any micro to macro level production plants which includes Food Processing, Steel Melting, Textiles, Foundries, Bulk Warehouses, Pharmaceutical, Oil Refineries, Chemical Processing, Packaging Industries, Transport Fleets, Convention Halls, Automobile Showrooms, Service Centers & many more…

pre engineered building structure

Get Price Quote

The name Pre-Engineered buildings (PEB), refers to buildings that are Pre Engineered & ready to deliver to customer. As long as the purchaser is restricted to standard designs, buildings could be called Pre-Engineered Buildings. Buildings which rely on Standard Engineering Designs for a variety of off-the-shelf configurations, wherein each component of the building comes pre-punched, marked, completely constructed to specifications off-site and then shipped to site.

Prefabricated Steel Building

Get Price Quote

Pre Engineered Buildings

Get Price Quote

A pre-engineered building (PEB) is designed to be fabricated using a pre-determined inventory of raw materials and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements. Historically, the primary framing structure of a pre-engineered building is an assembly of I-shaped members, often referred as I beams. In pre-engineered buildings, the I beams used are usually formed by welding together steel plates to form the I section. The I beams are then field-assembled (e.g. bolted connections) to form the entire frame of the pre-engineered building. Some manufacturers taper the framing members (varying in web depth) according to the local loading effects. Larger plate dimensions are used in areas of higher load effects. Other forms of primary framing can include trusses, mill sections rather than 3-plate welded, castellated beams, etc. The choice of economic form can vary depending on factors such as local capabilities (e.g. manufacturing, transportation, construction) and variations in material vs. labour costs.

Pre-Engineered Building

300 Per 300 Square Feet

Pre-Engineered Building, Installation, Supply, Designing Services

Pre Engineered Building

Get Price Quote

Design and Build Turnkey Projects, Interior Designing Services

pre engineered building structures

Get Price Quote

pre engineered building structures, Pre Painted Galvanized, Galvalume

Pre Engineered Buildings

Get Price Quote

A pre-engineered building (PEB) is designed to be fabricated using a pre-determined inventory of raw materials and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements. Historically, the primary framing structure of a pre-engineered building is an assembly of I-shaped members, often referred as I beams. In pre-engineered buildings, the I beams used are usually formed by welding together steel plates to form the I section. The I beams are then field-assembled (e.g. bolted connections) to form the entire frame of the pre-engineered building. Some manufacturers taper the framing members (varying in web depth) according to the local loading effects. Larger plate dimensions are used in areas of higher load effects.

Pre Engineered Buildings

Get Price Quote

Pre engineered buildings are professionally developed, structured and designed. And also possess smart appearance.

pre fabricated building

Get Price Quote

pre fabricated building, Material Handling Equipment

pre engineered building structures

Get Price Quote

pre engineered building structures, Steel Fabrication, Sky Lights