Coconut Pre Cutting Machine

125,000 Per Piece

1 Piece (MOQ)

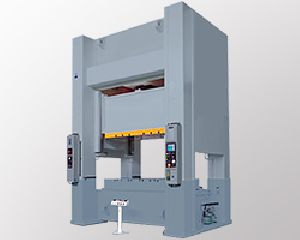

H Type Power Press Machine

Get Price Quote

For maximum customer satisfaction, we ensure that the product reaches the customer in the said time slot, owing to our reliable shipping facilities. Since, we are famous suppliers of H Type Power Press Machine, buyers can place order with us and quote their prices. Our H type power press machine is available with a quality warranty of 12 months against any manufacturing defect.

Best Deals from Pressing Machine

Nutritek Q3 Commercial Cold Press Juicer Machine

580,000 Per Piece

COMMERCIALS COLDPRESS JUICER MACHINE Capacity 8g-8tons 8kg capacity per batch,4 to 5 batch per hour,juice output 400 to 600ml per kg,8 tonns pressure,1 hp grater motor. The Nutritek Q3 is the first commercial juice press built specifically for juice on-demand. Now you can deliver Goodnature quality juice in our smallest footprint ever, one glass at a time. A commercial juicer for juice bars, restaurants, or even a home juicing business

Deep Drawing Press Machine

Get Price Quote

LINEAR WET PRESS - Linear Wet Press

Get Price Quote

Parijatha, with their long and rich experience in manufacturing Heavy duty Hydraulic presses have developed the SingleMould linear Wet press for manufacture of high density products.This machine can produce • Heavy duty Kerb stones,• Dished Channels• Drain covers and slabs• Flags• Heavy duty paving Slabs- Plain and designThe salient features of this very popular machine are:• Heavy duty frame with robust design and construction, capable of handling high pressure required for manufacture of wet pressed products.• Flexible Mould system with possibility to manufacture various sizes and profiles using the same Mother mould, just by changing a few tooling.• Specially designed hydraulic power pack for high pressure to the extent of 400 tons pressure, which is essential for manufacture of high density concrete products.• Custom built handling system for fast and smooth handling of the finished products.• All functions controlled by a single electrical panel with PLC control, designed for simplicity and ease of maintenance specially required for the industry.• Various options of concrete dosing and product handling systems can be offered as per customers specific requirements.The products manufactured by this process have the unique qualities of high compressive strength, very low water absorption, abrasion resistance and most importantly resistance to freeze – thaw cycles.The quality parameters achieved in this process is impossible to achieve in other processes. Moulds can be specially developed according to the customer’s specific requirements for various kinds / types of products.Unique Vacuum de watering system attached to the Press Head removes the water from the product. Easily replaceable filters ensure that only the water content is removed from the product and not the cement during the pressing process.

hydraulic press cum punching machine

Get Price Quote

We are offering hydraulic press cum punching machine. This machine is a combination of both pressing and punching of metals sheets. This machine is built using quality iron, internationally branded hydraulic components and electrical.

HYDRO JUMBO BAG PRESSING MACHINE

Get Price Quote

HYDRO Jumbo Bag Pressing Machine is a special FIBC Bags HDP Load Testing Machine. Four Loops, Two Loops and Single Loops can be tested Cyclic, SWL, and Peak Load test as per the standard.

servo press machines

Get Price Quote

SP Leak Test & Automation Pvt. Ltd. specializes in manufacturing servo press machines which are manufactured using supreme quality materials with the help of sophisticated tools and technology. These are available in different options as per the demands of clients. FEATURES OF SERVO PRESS MACHINES High performance through scalable and variable quantity structure on drive axes with high accuracy (in microns). Protection and monitoring functions with the emphasis on tool protection and press force monitoring. Flexible production through automatic calculation of an energy-optimized movement for the press plunger/control slide position and velocity—within microns. Force, torque, velocity graph can easily monitor for better performance. Compact & easy accessible electrical , pneumatic panel with all protections. Having all poke-yoke (fixture detection, part present detection, hole identification, part in rejection bin detection etc.) with tower lamp indication buzzer. Total safety with safety light curtain & alarm indication for all device divergent behavior , position of moveable instruments etc. Test result storage feasibility in PLC system. After Pressing, marking on component feasibility( Laser marking, Dot matrix marking, Dot punch/ letter marking etc..)

TWIN CYLINDER HYDRAULIC BLANKING PRESS

Get Price Quote

We have developed this twin cylinder compact hydraulic power press as an import substitute. It has a working area of 1.5 m long x 550 mm wide. The adjustable day light can be varied from 35 mm min. to 185 mm max. The parallelism between the moving ram and bed is 0.5 mm, which is being constantly maintained by the unique balancing valve mechanism. The mechanical balancing valve mechanism is envisaged to be a low cost substitute to the expensive servo valves. The 5 HP (3 KW) power pack capacity is 200 liters and is capable of developing 140 bar peak cutting pressure which is enabled by an innovative fly wheel mechanism, integrated with the motor. There is a manually operated stroke setting mechanism, enabled by a low pressure relief valve. Once the stroke is set, the same stroke length will keep repeating reliably.

Hydraulic Press Machine

571,000 Per Units

Rubber Mould Moulding Press Attachament Machine

Get Price Quote

We are engaged in offering Rubber Molding Press Attachament Machine that are used to check the rubber bond strength of metallic bush with rubber molding. Fabricated in compliance with established industrial standards, the machine caters various industrial requirements. The features associated with our molding machines are optimum performance, longer shelf life, low in noise level and power consumption and easy to install and operate. We also custom designed our range as per required by our client. Yes! I am interested

Hydraulic Frame Presses machine

Get Price Quote

Features The Hydraulic Frame Presses is designed of rugged construction and especially hi-power combined with accurate operation. The pressing action can be hydraulically locked at any position, so that, even at max. Power, the pressing frame are no less accurate, the upper frame side unit & the vertical cyl. Support are equipped with rules, convenient for operating, the vertical cylinder movement & positioning is employed the springs balances facilitates, due to various pressing case, the vertical & side cylinders can be moved randomly.

Baling Press Machine

246,000 Per Piece

Bale Press System

Get Price Quote

Reduced waste, lesser worries now possible with the Bale Press system by Luwa. Equipped to clean four different types of waste, it even reduces the amount of disposal waste. Useful in the manufacturing of cotton, blends and synthetics.Manufactured by: Luwa India Private Limited, India Technical Details Raw Material: Cotton, blends, synthetic etc Application: For textiles and nonwovens key Features It is possible to use a single bale press for up to four different waste types Bale Press is equipped with a complete waste management system The hydraulic Bale Press compacts textile waste to bales of standard size

Servo Controlled Positive Drive Screw Press

Get Price Quote

In a conventional Friction Screw Press, energy is transmitted from the transmission wheels to the flywheel by friction through a leather band. On the return stroke, energy stored in the moving parts is dissipated as heat by applying brake. In our machines, the two transmission wheels on the conventional Friction Screw Press are dispensed with. The flywheel is driven by an AC servo/ spindle motor through a timer belt/ gear. The motor can be made to run the flywheel at a preset speed very precisely till the dies come very close. The motor is now disabled and the entire energy in the moving masses gets transferred to the job. When the moving die comes to rest, the motor is reversed and the ram returns to its home position very precisely. Since there is no mechanical braking, no energy is wasted during return stroke. The motor brakes on line – regeneration principle where the kinetic energy in the moving mass is converted to electrical energy and sent back to the mains. Since the drive motor does not run when the ram is stationary no energy is consumed during idling of press

Laundry Steam Press Machine

245,000 Per Piece

Coil Press Machine

7,500,000 Per Piece

1 Piece (MOQ)

bush pressing machine

Get Price Quote

Leveraging over the skills of our qualified team of professionals, we are instrumental in offering wide range of Bush Press Machine.

Pneumatic Press Machine

80,000 - 150,000 Per Nos

1 Bag (MOQ)

We all Smc cylindr filo press

Mushroom Press Machine

275,000 Per Piece

1 Piece(s) (MOQ)