Vertical Winding Machine

Transformer magnetic cores are produced of high quality silicon grain oriented electric steel with low and extra low specific loss including steel with laser treatment Electric steel length cutting is carried out on George automatic slitting lines. Core-plates are cut on GEORG (Germany) high-precision automatic CNC cross-cutting lines equipped with hard-alloy tools and V-dies. The sector of automatic line of cross cut electro steel cutting Georg with Pressing and packing of finished E-core is responsible for automated cutting and assembling of transformers' core. It is automatic core slitting and cutting machine and its core assembly lifting platform capacity 150 MT. Automatic core Slitting machine with de-burring attachment for burr-free laminations– from Georg GmbH, Germany Automatic core cutting machine with v-notch cutting, hole piercing, step-lap joints and stacking facilities - from Georg GmbH, Germany with dedicated 10 MT EOT Crane.

...more

LV Winding Machine

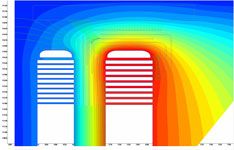

PML offers power transformers incorporating most modern technologies meeting its customers’ expectations and relevant standards at the lowest possible cost. An array of software programs are employed to arrive at the optimum design and calculate the expected behavior of the transformer at test and in service from all aspects. Our 3-D CAD engineering system allows us to review the complete internal and external design of a transformer before assembly eliminating errors and defects at production stage. Design Optimization Best feasible design is selected by varying flux density, winding current densities, core height, CRGO grade, conductor type etc. Current distribution in windings, magnetic flux distribution in core, Impedances, Optimum places for transposition, load loss, no-load loss, sound level, hydraulic calculation of cooling system, heating of core and windings etc. are calculated and verified to be within acceptable limits.

...moreBe first to Rate

Rate This