Reverse Engineering Services

Get Price Quote

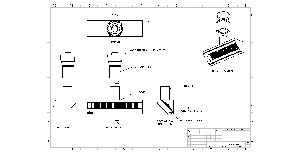

Our reverse engineering services unlock the secrets of existing products or systems, offering valuable insights for innovation, improvement, or replication. Using state-of-the-art technologies and methodologies, we meticulously analyze and deconstruct components, structures, or processes to understand their functionality, materials, and design principles. Key Features: 1. Comprehensive Analysis: With a keen eye for detail and engineering expertise, we conduct thorough analysis and documentation of existing products or systems. This includes examining components, materials, and design intricacies to uncover hidden insights. 2. Precision Documentation: We utilize advanced tools and techniques to create precise CAD models, schematics, or prototypes based on our findings. This enables us to accurately replicate or enhance existing designs for various purposes. 3. Innovation and Improvement: Whether it's for product enhancement, troubleshooting, or competitive analysis, our reverse engineering solutions empower businesses to drive innovation and stay ahead in today's dynamic market. By understanding the inner workings of existing products, we provide opportunities for improvement and differentiation. 4. Collaborative Partnership: Partner with us to unravel complexities, optimize performance, and drive innovation in your projects. We work closely with clients to understand their specific needs and goals, delivering customized solutions that meet and exceed expectations. With our reverse engineering expertise, businesses can gain valuable insights, optimize performance, and drive innovation in their projects. Let us help you unlock the full potential of your products or systems.

Mechanical Engineering Design Development Services

Get Price Quote

undefined undefined (MOQ)

Looking for Product Prototyping Services Providers

Reverse Engineering Services

Get Price Quote

Determination of component product characteristics, dimensional measurements, materials testing, manufacturing process identification, drawing & specification development, prototype development, validation etc.

Prototype Manufacturing Service

1,200 - 2,400 Per Hour

From concept to prototype, DFMEA Technosol team of highly skilled design engineers will turn your design concept into a model or working prototype. We will work with you, the designer, to develop a prototype that meets your needs. Whether you need a Proof-of-Principle prototype to demonstrate a concept, a Form Study Prototype to evaluate a design, a User Experience or Visual Prototype for marketing or user jury purposes, or a Functional Prototype to verify requirements – DFMEA Technosol has a solution for you We are support in coordinating Labs for generating LCF, HCF, Creep Curve, Mechanical and Thermo-Physical properties of any material. We also support in developing Jigs, Fixture and tools for machining and casting. We also support in Reverse engineering for any complex parts.

mold designing service

Get Price Quote

VSP Tool Craft is known widely for the mold designing services in India. There are plenty of companies who require mold to produce different kinds of products that they are not able to produce otherwise. The mold designs that we provide to our customers have renewed different projects. We are proud to help our customers with products that fulfill their needs and requirements. The finished products are Eco-friendly and can be used of years without any problem. We design these mold according to the needs and requirements of our customers and clients. These helps prevent the cost of catastrophic and the product fails. Choose us and get our designing services today. Contact us to know more.

HR Process Consulting & Re-Engineering

Get Price Quote

Our consultants assist you in strategically integrating effective HR processes, programs and practices into your daily operations. Our role is also to maximize the client’s performance related to human resources by introducing or marketing best practice products or services, as well as to provide periodic feedback.

Scale Model

Get Price Quote

We are offering scale model. It is an established practice that model making of machinery scale down the actual machinery design to miniature models keeping most of the critical and important features of the original machinery. They are professional and well established engineering companies housing several highly qualified engineers, architects and design engineers and also called as scale model making. Several big and established manufacturing industries generally make the critical and important machinery into miniature models for various purposes. Some companies usually display these models in their corporate offices and conference or board rooms. Most of the cement companies and power companies utilize the services of scale model making for this purpose and make models of cement kilns, hoppers, turbines etc and exhibit these models to provide a glimpse of the actual machinery for common people, customers, board of directors, and visitors. scale model making are highly qualified and specialized engineering industries and capable of producing prototype models of very critical machinery using some industrial grade acrylic, pvc, and poly carbonate material based on the requirements of the clients. The selection of the raw material to design and fabricate this machinery depends on the critical aspects of the original machinery. scale model making also develop prototype models of high end and complex machinery of various industries and serve several high end engineering colleges. Several laboratories of prestigious engineering colleges and management institutes keep these models in order to educate the students. Model making is a very critical and highly sophisticated area of engineering application and this industry is essential for the development of the engineering industry.

prototyping

Get Price Quote

We provide services of Designing and supporting the Process of Prototyping to test new innovative solutions

Reverse Engineering

Get Price Quote

Reverse engineering is a misnomer to the word “copying”. One can physically copy a machine or a tool or a fixture; but he needs an engineering perception to copy the soul of that equipment. The soul or finer point of a machine is subtle and cannot be seen by one and all with their plain eyes. It needs an inner eye. The soul of a machine can be its metallurgy, hardness, manufacturing and assembly tolerances etc. It needs an in-depth knowledge of engineering principles, which is the fruit of years of hands-down experience in the shop floors. We are equipped to accept challenging assignments in reverse engineering of machine tools. We have developed a number of import substitutions like Universal Milling Attachment, Multi Angle right angle attachment, Stamping Press etc. FOAM SLICING AND CUTTING CNC MACHINE Foam slicing through a CNC band-sawing process is very fast and it produces the sheets of the same and controlled thickness. We have designed and have built a FOAM SLICING & CUTTING CNC SPM for the manufacturer of automobile filters, which are made of foam cubes or buns of different sizes. These cubes are to be sliced into long sheets of different thickness accurately. The CNC Slicing SPM is designed to perform this precision, long, thickness uniformly controlled, slicing operation, so that the maximum numbers of slices are sliced off from the cubes, repeatedly. The encoder based feed system ensures accurate positioning of the slicing saw blade to accurate position in the vertical axis continuously and repeatedly from one pass to the other and without variation. The linear motion guideways and ball lead screws for the vertical and longitudinal axes facilitate smooth sliding movements. Variable rotational drive to the cutting blade Variable and accurate positioning of the cutting blade with respect to the job in vertical axis Variable and accurate feeding of the job to the cutting blade in the longitudinal axis. Capacity: for slicing 2 mtrs long x 1.5mtrs wide x 0.6 mtr height blanks or any other capacity, as required Latest Siemens CNC system Hiwin (Thaiwan) make ball lead screws, box nut & LM guide ways Cenlub make of automatic lubrication system Siemens or ABB make of VFD for blade rotating mechanism Blade sharpening cup wheel of dia 100 mm or dia 125 mm Blade rotating surface speed: 15 mtrs per second, which can be increased or decreased with the help of VFD Blade guide area in the wheel is rubber coated for minimizing noise Blade grinding unit located in such away that the grinding particles do not fall on the machine or on the foam blank Counter balancing mechanism for the blade rotating unit whenever required. Electrical switch gear elements, limit switch etc are of Siemens make Manual and auto modes are provided. Variable zero position is provided for the blade, considering varying heights of the foam blanks. Control circuits suitable for 24V DC Emergency “off” switch at a convenient location Anti vibration mounts for avoiding foundation, leveling and for ensuring sufficient clearance for cleaning. Machine Lamp Machine color: combination of Siemens grey and blue Bellows for the vertical guide ways, table guide ways & for the table lead screw. Protective guard for the blade assembly Machine design & construction compatible for easy for dismantling and re-assembly.

software product engineering

Get Price Quote

Euphoric Thought has established a reputation for its agile approach to product development. We have a highly skilled and diverse team that brings a wealth of knowledge and experience to the table. Our solutions prioritize innovation and scalability, adding value to our client’s offerings. From legacy modernization to new builds, we ensure product security, scalability, and user engagement.

Engine Working Models

Get Price Quote

Die Mould Designing Services

Get Price Quote

Classic Engineering is committed to developing and selling Die Mould Designing Services primarily for usage in the injection moulding and diecasting businesses. Die Mould Equipment provides plastic injection moulding services for a wide range of materials, including engineered polymers. We make bespoke components with high tolerance and exact dimensions to your specifications. Our bespoke components are tailored to your business, and we have collaborated with organisations in a variety of industries such as aircraft, oil and gas, utilities, civil industries, medical devices, and telecommunications. Our competence fosters evolutionary processes that are focused on tight tolerances, cost-effective production, and on-time delivery. We have continually been a leading company in new technology development and take satisfaction in being the first to provide technologies that assist mould production.

mold designing

Get Price Quote

Mold Design is one of the most important facets of the production process because it’s the earliest opportunity to prevent expensive mistakes later on. There are many objectives to design for: function, aesthetics, manufacturability, assembly, etc. The right design is one that accomplishes the required objectives to a satisfactory level, but it may take a lot of creativity to get there.Our team provided you the best mold design solutions. We believe and follows the principle of scientific molding in solving the problems. Our capablities also includes Moldflow analysis, that helps clients to provide deeper insights of the whole process. Also we aid clients in design and development of all plastic components. Our company strongly believes in and obeys all your IPR.Feel free to contact us for any of your queries on Injection Mold Designing.

Product Engineering design services

Get Price Quote

Complete development assistance from concept to launch of mechanical subsystems along with coordination with other functions.

Mechanical Engineering

Get Price Quote

As a provider of highly customer-centric consulting, engineering services, we offer you a seamless one-stop experience alongside high quality and timely delivery.

Engineering Models

Get Price Quote

We provide the best services of architectural models, 3d models, engineering models, plant models, building models for your business.

Mold Design Services

Get Price Quote

We are offering mold design services.

prototype development service

Get Price Quote

Zen provides prototype development service. Do you have a component or a product to be developed but lack in-house expertise. Zen Engineers helps you achieve this. All you need to provide us with your ideas and specifications. Zen will develop prototypes as per your specifications to suit your correct requirements.

mold design

Get Price Quote

We are providing mold design.

Product Engineering service

Get Price Quote

We are offering product engineering service.