Reverse Engineering Services

Get Price Quote

Our reverse engineering services unlock the secrets of existing products or systems, offering valuable insights for innovation, improvement, or replication. Using state-of-the-art technologies and methodologies, we meticulously analyze and deconstruct components, structures, or processes to understand their functionality, materials, and design principles. Key Features: 1. Comprehensive Analysis: With a keen eye for detail and engineering expertise, we conduct thorough analysis and documentation of existing products or systems. This includes examining components, materials, and design intricacies to uncover hidden insights. 2. Precision Documentation: We utilize advanced tools and techniques to create precise CAD models, schematics, or prototypes based on our findings. This enables us to accurately replicate or enhance existing designs for various purposes. 3. Innovation and Improvement: Whether it's for product enhancement, troubleshooting, or competitive analysis, our reverse engineering solutions empower businesses to drive innovation and stay ahead in today's dynamic market. By understanding the inner workings of existing products, we provide opportunities for improvement and differentiation. 4. Collaborative Partnership: Partner with us to unravel complexities, optimize performance, and drive innovation in your projects. We work closely with clients to understand their specific needs and goals, delivering customized solutions that meet and exceed expectations. With our reverse engineering expertise, businesses can gain valuable insights, optimize performance, and drive innovation in their projects. Let us help you unlock the full potential of your products or systems.

Reverse Engineering Services

2,500 Per Component

Reverse Engineering Solutions in Bangalore at Quality Laboratory Have a finished product but no design files? Reverse engineering is the ideal solution to recreate STL data and CAD models, enabling accurate inspection and seamless manufacturing. Reverse engineering, also called "backward engineering," involves analyzing an existing object to understand its design, function, or production process. By utilizing advanced tools and techniques, reverse engineering reconstructs digital models of a product with minimal information about its original design. At Quality Laboratory, we specialize in reverse engineering using advanced technologies to deliver highly precise results. Our process includes: Portable laser scanners: These capture precise digital data, generating accurate models that closely replicate the original product. Carl Zeiss PRISMO CMM with a rotary table: Provides precision measurement for complex components. Non-contact VMS system: Ensures detailed measurements for enhanced accuracy. 3D inspection services: Compare components against CAD models and provide detailed reports for in-depth analysis. We offer expertise in reverse engineering gears (spur and helical), prismatic profiles, and freeform surfaces, ensuring reliable and tailored solutions for various industries. KSCAN – MAGIC COMPOSITE 3D SCANNER Our KSCAN – MAGIC COMPOSITE 3D SCANNER enhances reverse engineering efficiency and accuracy. Equipped with cutting-edge infrared laser + blue laser technology and a built-in photogrammetry system, it captures ultra-high details across five working modes. Its flexibility allows scanning parts ranging from a few centimeters to several meters, making it suitable for various applications, including: Industrial design and quality control Reverse engineering 3D digitalization of cultural artifacts 3D film, gaming, and VR/AR applications Whether you’re recreating a lost design, optimizing an existing product, or inspecting components for manufacturing, Quality Laboratory provides precise and reliable reverse engineering services. Partner with us for tailored solutions that meet your needs. Contact Quality Laboratory today to learn more!

Looking for Reverse Engineering Services Providers

Reverse Engineering Services

Get Price Quote

Determination of component product characteristics, dimensional measurements, materials testing, manufacturing process identification, drawing & specification development, prototype development, validation etc.

Reverse Engineering

Get Price Quote

Reverse engineering is a misnomer to the word “copying”. One can physically copy a machine or a tool or a fixture; but he needs an engineering perception to copy the soul of that equipment. The soul or finer point of a machine is subtle and cannot be seen by one and all with their plain eyes. It needs an inner eye. The soul of a machine can be its metallurgy, hardness, manufacturing and assembly tolerances etc. It needs an in-depth knowledge of engineering principles, which is the fruit of years of hands-down experience in the shop floors. We are equipped to accept challenging assignments in reverse engineering of machine tools. We have developed a number of import substitutions like Universal Milling Attachment, Multi Angle right angle attachment, Stamping Press etc. FOAM SLICING AND CUTTING CNC MACHINE Foam slicing through a CNC band-sawing process is very fast and it produces the sheets of the same and controlled thickness. We have designed and have built a FOAM SLICING & CUTTING CNC SPM for the manufacturer of automobile filters, which are made of foam cubes or buns of different sizes. These cubes are to be sliced into long sheets of different thickness accurately. The CNC Slicing SPM is designed to perform this precision, long, thickness uniformly controlled, slicing operation, so that the maximum numbers of slices are sliced off from the cubes, repeatedly. The encoder based feed system ensures accurate positioning of the slicing saw blade to accurate position in the vertical axis continuously and repeatedly from one pass to the other and without variation. The linear motion guideways and ball lead screws for the vertical and longitudinal axes facilitate smooth sliding movements. Variable rotational drive to the cutting blade Variable and accurate positioning of the cutting blade with respect to the job in vertical axis Variable and accurate feeding of the job to the cutting blade in the longitudinal axis. Capacity: for slicing 2 mtrs long x 1.5mtrs wide x 0.6 mtr height blanks or any other capacity, as required Latest Siemens CNC system Hiwin (Thaiwan) make ball lead screws, box nut & LM guide ways Cenlub make of automatic lubrication system Siemens or ABB make of VFD for blade rotating mechanism Blade sharpening cup wheel of dia 100 mm or dia 125 mm Blade rotating surface speed: 15 mtrs per second, which can be increased or decreased with the help of VFD Blade guide area in the wheel is rubber coated for minimizing noise Blade grinding unit located in such away that the grinding particles do not fall on the machine or on the foam blank Counter balancing mechanism for the blade rotating unit whenever required. Electrical switch gear elements, limit switch etc are of Siemens make Manual and auto modes are provided. Variable zero position is provided for the blade, considering varying heights of the foam blanks. Control circuits suitable for 24V DC Emergency “off” switch at a convenient location Anti vibration mounts for avoiding foundation, leveling and for ensuring sufficient clearance for cleaning. Machine Lamp Machine color: combination of Siemens grey and blue Bellows for the vertical guide ways, table guide ways & for the table lead screw. Protective guard for the blade assembly Machine design & construction compatible for easy for dismantling and re-assembly.

Reverse Engineering Services

Get Price Quote

Enti provides reverse engineering and value engineering services for electronic hardware modules and subsystems, mechanical components and software systems. Our services for hardware include identification of functions, design modifications, software implementation and new design development for maintaining form and fit.

Reverse Engineering Services

Get Price Quote

Product Designing, computer aided designing, Enclosure Designing

Reverse Engineering Services

Get Price Quote

Mechanical CAD Drafting, Cad Outsourcing Services, cad drawing

Reverse Engineering Design Services

Get Price Quote

Reverse Engineering Design Services, machine vision

Reverse Engineering Services

Get Price Quote

Engineering Services, Welding Jig, Positioner Engine Block, Tack Welding Jig

Reverse Engineering Services

Get Price Quote

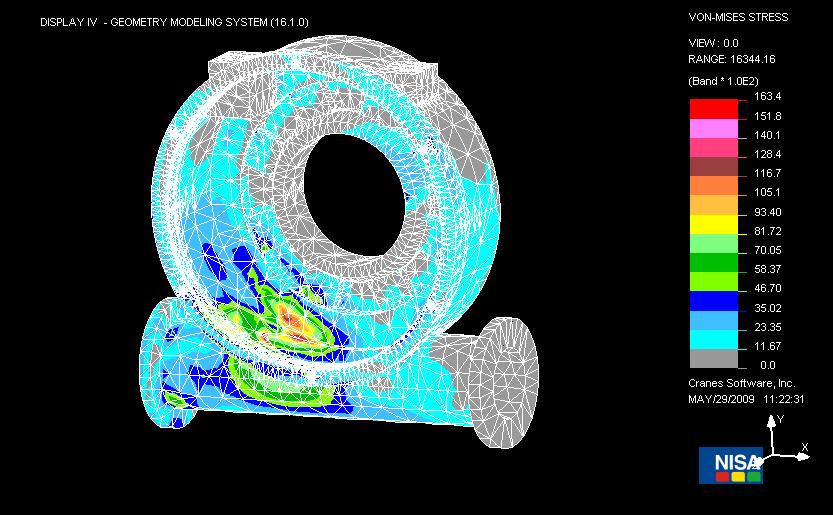

finite element analysis, Laboratory Equipment, process planning simulation

Reverse Engineering Services

Get Price Quote

laser tracking services, laser tracker inspection, 3d laser scanning

Reverse Engineering Services

Get Price Quote

air transport services, Transportation Services, kitchen storage rack

Reverse Engineering Services

Get Price Quote

laser scanning services, cad to part inspection services

Reverse Engineering

Get Price Quote

Reverse Engineering, Printed Circuit Board, electronic systems

Reverse Engineering Services

Get Price Quote

Engineering Service, prototype models service

reverse engineering service

Get Price Quote

reverse engineering service, Engineering Design Services

Reverse Engineering

Get Price Quote

Reverse Engineering, 3d modelling, tooling, rapid tooling

Reverse Engineering

Get Price Quote

Reverse Engineering, Granite Surface Plate, GRANITE SQAURE