Sandwich Puf Sheet

Get Price Quote

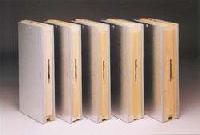

Metal-faced polyurethane Sandwich Puf Panels are the system of choice of today for large industrial buildings, refrigerated warehouses, office blocks, exhibition halls, fair pavilions, schools, and sports halls. Polyurethane Sandwich Puf Panel from Viraat Industries, the leading Sandwich Puf Panels Manufacturers, comes complete with specially formed tongue-and-groove joints ensuring a perfect fit and maximum integrity. The assembly is fast, easy, and cost-effective. Being the industry's most reputed Sandwich Puf Panel Manufacturers, the resultant sandwich panel we manufacture is engineered with a load-bearing capability many times greater than the one achieved by adding together the load-bearing capacities of the individual layers. As a result, these thin, relatively lightweight sandwich panels can safely bridge wide spans.

Cold Store & Blast Freezer Puf Panel

2,000 Per Square Meter

1000 Square Meter (MOQ)

Best Deals from Sandwich Panels

100MM PUF WALL PANEL

1,657 Per Square Meter

Alfa Peb Limited is India's No.1 Manufacturer of puf panel with 3 fully automated manufacturing units. Having the largest manufacturing capacity of 5 Lakhs sqmtr per month. Metal-faced polyurethane sandwich panels are the system of choice today for large industrial buildings refrigerated warehouses, office blocks, exhibition halls, fair pavilions, schools, and sports halls. The aluminum or steel facings themselves are surface coated and can be manufactured with profiles of various depths leading to a higher load-bearing capacity. Polyurethane sandwich panels come complete with specially formed tongue-and-groove joints ensuring a perfect fit and maximum integrity, Assembly is fast, easy, and cost-effective. As a result, these thin, relatively lightweight sandwich panels can safely bridge wide spans. Available Panel Thickness: 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm

clean room panels

11 Per Square Meter

100 Square Meter (MOQ)

Glass Wool Sandwich Panel

15 Per Square Feet

PUF Roofing Sheets

Get Price Quote

500 Square Meter (MOQ)

Puf Insulated Panels

1,100 - 1,525 Per Square mtr

6.42 Square mtr (MOQ)

A Flame Spread Property: B3 as per DIN 4102 (B2 & PIR upon request) Insulation Capacity

Puf Insulated Panels

Get Price Quote

Polyurethane Sheets, cast polyurethanes, Polyurethane Products

Rock Wool Board

Get Price Quote

Rock Wool Board

Get Price Quote

Polyurethane Sheets, Polyurethane Roller, Polyurethane Sealants

Sandwich Puf Panels

Get Price Quote

PUF is a composite panel, they consist of an Insulating Layer of Rigid Polyurehene Foam sandwiched between two layers of metal sheets Thickness available : 30 mm – 100 mm Applications: Malls, Buildings, offices, Auditoriums etc. Cold Storages. Refrigerated Rooms. Pharmaceutical Buildings. Structural Insulations(Roofs, Walls). Features Sandwich Panels with PUF insulations have longer life as compared to other insulation materials. PUF Sandwich Panels are rigid and sturdy with higher mechanical strengths. Has a high fire resistance rating. High load bearing capacity at low weight Excellent and durable thermal insulation absolute water and vapour barrier Excellent air tightness and free of thermal bridges which results in considerable energy savings. Capacity for rapid erection without lifting equipments; easier installation in hostile weather conditions Easy repair and replacement in case of damage Long life and very low maintenance cost Good sound resistance

Cam Lock Sandwich Panel

Get Price Quote

We are putting forth a moderate scope of Cam lock Sandwich Panel for roofing, divider cladding and cold room walling. These boards involves two facings of generally thin metal sheet profiled of high quality encasing a center, which is moderately thick and light with obliged solidness.

sandwich sheet

Get Price Quote

Building construction with pre-fabricated sandwich panel systems made of pre-painted galvanised steel with sandwiched rigid PIR PUR insulation, helps to create sturdy, aesthetic buildings that save money, time, effort, and skill.

rockwool slab

15 Per Square Feet

PUF Panels

Get Price Quote

sandwich puf panel

128 Per Square Feet

Sandwich Roof Panels

Get Price Quote

An innovative solution for walling and roofing giving added insulation properties along with Engineering Strength in building and construction. Made on state-of-the-art plant and of superior in quality. Great energy saver and hence indispensable in air-conditioned, cooled and heated buildings. Versatile and suitable for all types of built environment starting from residential blocks to offices, warehouses, commercial complexes, site offices, telecom shelters, etc.. Cost effective and bring down life cycle cost for any built environment. Virtually zero maintenance throughout its usage life. Unique Features: • Structurally strong with fantastic insulation.• Light weight and easy to install.• Reduce steel framework and load bearing foundation considerably.• Superior and proprietary tongue and groove system, hence leak proof and easy to fix.• Available in customized length as per requirement to reduce number of joints and installation cost.• Facing made of top quality metallic colour coated sheets and guaranteed for long life.• Varieties of finishes available to match aesthetic needs.• Much thinner than traditional walls and increase floor space. Sintex Insulated Roofing is made with high quality colour coated steel sheets or Galvalume sheets of superior quality that are corrosion resistant for many decades. FEATURES: • Specially designed crown overlapping for 100% leak-proof construction• Greater strength as compared to simple roofing that will increase purlin spacing and bring down the cost of frame for installation• Lightweight and extremely easy to install• Long life due to special colour coated sheets of superior quality• 100% maintenance-free• Aesthetically designed• Sound insulation because of sandwich PU foam• Enhanced comfort level and hence, useful for all types of constructions

Polyurethane Sandwich Panel

Get Price Quote

Polyurethane sandwich panels come complete with specially formed tongue-and-groove joints ensuring a fit and maximum integrity. Assembly is fast, easy and cost effective. The resultant sandwich panel has a load-bearing capability many times greater than that achieved by adding together the load-bearing capacities of the individual layers. As a result, these thin, relatively lightweight sandwich panels can safely bridge wide spans. For example, a panel just 100mm thick can easily bridge a clear span of some 6 meters.

White PUF Pipe Section

320 Per Meter

100 Meter (MOQ)

eps cement sandwich panel

Get Price Quote

It is lightweight energy-saving panel used as the wall or roof for residential, cold storage, workshop & industrial projects as they offer a wide range of uses and applications like Partitioning, Acoustic and Sound Insulations. Thermal and acoustic properties offer a highly efficient acoustic system that reduces noise levels that emanate from roads, freeways and rail corridors. Heating and cooling are reduced with the use of the lightweight wall panels providing insulating thermal properties. Panel thickness can be constructed according to will need and purpose of the customers. Impact resistance, compression strength, shear strength, and panel weight are all of the things built right in as combination components that produce the lightweight wall panels. JITEX EPS CEMENT SANDWICH PANEL is a non-corrosive building construction panels which are used for Partitioning, Sound & Thermal insulations, Acoustic applications. This panel can be used for any Residential or commercial projects as they offer a wide range of uses in a lower price range.It has very good fire resistance, tolerates damp and is not attacked by mold or rot.it also have good resistance to insect, and pests. Compared to many other lightweight insulation materials, it has better strength with low cost. They are often used for lightweight partitioning which absorbs sound & provides fire resistance in factories, public gathering places, sports and concert halls.