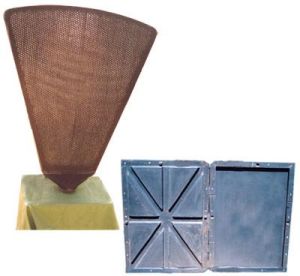

FRP GRP Tanks

FRPGRP tanks are used for numerous industries and sectors. The FRPGRP tanks manufactured by us contain high quality of materials for storing acids, water, alkalis and other liquid items. These tanks contain thick base for ensuring proper storage of the items. These tanks are available in various sizes and patterns as these are used for storing ferrous sulphate; dilute H2SO4, acetic acid, gasoline, hydrogen peroxide, chromic acid, phosphoric acid, chlorine, ammonium hydroxide, nitric acid , brine, etc.

Material : FRP, GRP

Shape : Round

Application : Storage Use

Color : Brown

Capacity : 500-1000L

Surface Finishing : Coated

...more

grp tanks

FRPGRP tanks manufactured and supplied by us have several features like chemical resistance from outside and inside, easy in maintenance, industrial fumes, and any other weather condition cannot make any harm to them, light in weight, and easy in modification, modest in initial costs. We manufacture FRPGRP tanks that can resist various acids and chemicals at temperatures of –40 deg C to 160 deg C and make them in proper shape and size to preserve the items. These tanks are manufactured as per customers’ specified shapes and sizes using destructive pattern method.

...more

grp motor guards

We manufacture FRPGRP motor guards with chemical resistant materials which are widely used by several industries. FRPGRP motor guards manufactured and supplied by us protect element from high voltage, phase reversal, loss of the power and avoid nuisance tripping. These motor guards are the safest and cheapest motor guards used to protect the electrical appliances from any kind of over heating or breaking of power. It is the motor guard that protects the electric appliances from the fluctuation of the power and any sort of damage. There are numerous advantages of FRPGRP motor guards: Electrical insulation of Class F. Thermal Insulation against high temperature. Prevention against electrical shock. Fire retardant characteristics (Optional).

...more

GRP Fiberglass Products

We, Saphire Polymers, manufacture FRPGRP fiberglass products by using wet lay up process with match die moulding for double side finish, single side smooth contact moulding, and PPPVC lined with FRPGRP moulding. We use following procedure for manufacturing these products- Gel coat made from aerosiltalk powder, chalk powder mixed with liquid thermosetting plastic called resin which is applied on the mould depending upon the individual requirements of the products constituting up to 0.3mm thick of the product. A layer of CSM (chopped strand matt) is laid on the dried gel coat and wetting of the same is done using resin. Subsequent layers of Owen roving or CSM are laid with procedure to build up the thickness of desired level. In case of match die moulding the moulds are matched and excess resin is squeezed with fasteners to lock the moulds.

...more

grp enclosures

FRP (Fiber-Reinforced Plastic) and GRP (Glass-Reinforced Plastic) enclosures have been used for several decades in various sectors and industries. The FRP enclosures manufactured by us possess following attributes: Maintenance free operations. Non-corrosive and immune to galvanic or electrolyte erosion. Lower maintenance cost and long lasting services. Lower thermal expansion. Can withstand high vibration and impact forces. Ability to fabricate multi directional mechanical properties. Excellent fatigue and fracture resistance. Simplification of manufacturing by having whole unit as an integral piece without joints or welds. Lower tooling cost alternatives.

...more

FRP Tanks

FRPGRP tanks are used for numerous industries and sectors. The FRPGRP tanks manufactured by us contain high quality of materials for storing acids, water, alkalis and other liquid items. These tanks contain thick base for ensuring proper storage of the items. These tanks are available in various sizes and patterns as these are used for storing ferrous sulphate; dilute H2SO4, acetic acid, gasoline, hydrogen peroxide, chromic acid, phosphoric acid, chlorine, ammonium hydroxide, nitric acid , brine, etc.

...more

Frp Motor Guards

We manufacture FRPGRP motor guards with chemical resistant materials which are widely used by several industries. FRPGRP motor guards manufactured and supplied by us protect element from high voltage, phase reversal, loss of the power and avoid nuisance tripping. These motor guards are the safest and cheapest motor guards used to protect the electrical appliances from any kind of over heating or breaking of power. It is the motor guard that protects the electric appliances from the fluctuation of the power and any sort of damage. There are numerous advantages of FRPGRP motor guards: Electrical insulation of Class F. Thermal Insulation against high temperature. Prevention against electrical shock. Fire retardant characteristics (Optional).

...more

FRP Fiberglass Products

We, Saphire Polymers, manufacture FRPGRP fiberglass products by using wet lay up process with match die moulding for double side finish, single side smooth contact moulding, and PPPVC lined with FRPGRP moulding. We use following procedure for manufacturing these products- Gel coat made from aerosiltalk powder, chalk powder mixed with liquid thermosetting plastic called resin which is applied on the mould depending upon the individual requirements of the products constituting up to 0.3mm thick of the product. A layer of CSM (chopped strand matt) is laid on the dried gel coat and wetting of the same is done using resin. Subsequent layers of Owen roving or CSM are laid with procedure to build up the thickness of desired level. In case of match die moulding the moulds are matched and excess resin is squeezed with fasteners to lock the moulds.

...more

frp cabinets

FRP (Fiber-Reinforced Plastic) and GRP (Glass-Reinforced Plastic) enclosures have been used for several decades in various sectors and industries. The FRP enclosures manufactured by us possess following attributes: Maintenance free operations. Non-corrosive and immune to galvanic or electrolyte erosion. Lower maintenance cost and long lasting services. Lower thermal expansion. Can withstand high vibration and impact forces. Ability to fabricate multi directional mechanical properties. Excellent fatigue and fracture resistance. Simplification of manufacturing by having whole unit as an integral piece without joints or welds. Lower tooling cost alternatives.

...more

cabinets

FRP (Fiber-Reinforced Plastic) and GRP (Glass-Reinforced Plastic) enclosures have been used for several decades in various sectors and industries. The FRP enclosures manufactured by us possess following attributes: Maintenance free operations. Non-corrosive and immune to galvanic or electrolyte erosion. Lower maintenance cost and long lasting services. Lower thermal expansion. Can withstand high vibration and impact forces. Ability to fabricate multi directional mechanical properties. Excellent fatigue and fracture resistance.

...moreBe first to Rate

Rate ThisOpening Hours