Wet Processing Machine

Wet processing machine SCHMID-GROUP, Germany SURFACE TECHNOLOGY BRUSHING + CLEANING LEVELLING + CLEANING OXIDE REPLACEMENT STRUCTURING + CLEANING SURFACE FINISHING RESIST TECHNOLOGY DES CHEMICAL MILLING REGENERATION SES DESMEAR + METALLIZATION DESMEAR DIRECT METALLIZATION ELECTROLESS COPPER ELECTROPLATING IMMERSION TIN AUTOMATION + MEASURING EQUIPMENT Buffer Conveyor Panel Measuring Table Unloader + Loader VERTICAL PROCESSING VERTICAL SPRAY PROCESSING EQUIPMENT Standard Brushing machine The standard brushing machine is primarily used for the deburring and cleaning of drilled PCBs. Thin inner layers are brushed bi-directionally at a high oscillating frequency. The distance between the brushes and the panel is automatically adjustable. The copper centrifuge "Cecumat" removes the copper abrasion from the rinsing water. DEVELOP-ETCH-STRIP======DES Developing - Etching - Stripping. In a typical inner layer line the non-exposed resist is developed in the developer, the bare copper is sprayed with an acid etching solution in the etching module and removed down to the base material and the resist is stripped off by using an alkaline solution. With outer layers the photo resist is used to define the pattern of an additionally deposited metal resist layer and is removed in the stripper using an alkaline solution. Strip Etch Strip====SES Stripping - Etching - Tin stripping. In the production of outer layers, photo resist is used for the structuring of an additional, deposited layer of metal resist, and then removed again in the stripper. The exposed copper is etched off in the alkaline etching module down to the basic material and the metal resist (Sn) is removed in a tin stripping system ELEctro Plating Line The galvanic plating system NTwC features a segmented contact frame, which permits contact of the panels only along the side edges and ensures an even copper deposition. During the plating process, the pulse form is controlled by rectifiers. The targeted flooding with fluid jets provides an optimum electrolyte exchange. Vertical Spray Processing Equipment Vertical processing has many considerable advantages such as little footprint, a service-friendly design and a contact-free transport system. Most notably vertical processing allows a double-sided symmetric chemistry treatment by identical process conditions on both sides of the substrate. This is especially beneficial in etching: by using a special chemistry that only is effective when hitting the substrate, the process result is absolutely homogeneous and the well-known puddling effect that occurs in horizontal etching is completely eliminated. Still up to today elaborate intermittent spraying techniques are necessary in trying to compensate this puddling effect. The Vertical Transport with Clamping (VTwC) is available for all spray applications: precleaning, resist and soldermask developing, flash etching, CuCl etching, resist stripping and MEC etch bond.

...more

Wet Process Equipment

Wet processing brushing machine for METAL SURFACE TREATMENT DEBURRING OF SHARP CORNERS, HOLE EDGES AND IRREGULAR PERIMETERS Main features Vertical axis rotating and oscillating brushes No holes ovalization Control by PLC complete with touch screen Settable brush abrasion Automatic autozero procedure Adjustable brush speed Adjustable belt conveyor speed Different brush grits combinations are possible to perform different surface treatments

...more

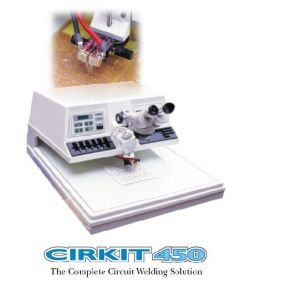

Track Welding System

AIN FEATURES PAlRS TRACKS >0.002” (0.05mm) Easy to use ‘Tactile’ controls Fully Adjustable Low Pressure Weld Head Auto ‘Electrode Contamination’ Indication Low Voltage Safety Circuitry 99 Prog. Memory with Manual Override Repairs Bare and Assembled PCB’s Large Work-Piece Capacity Adjustable Worklamp Output Low Maintenance

...more

Solder Mask Spray Coating System

Spray coater for Solder Masking The salient features of Spray Coater are given below. Innovated Design with direct extraction. Solder mask application is very uniform irrespective of circuit pattern and thickness of Copper. Also coating thickness as compared to Screen printing is much more uniform over edges as well as on surface. Coating thickness can be controlled effectively. Minimum cleaning & maintenance efforts (extended filter-elements – easy to replace). Long term approved ink supply system. Atomized air can be heated up till 100°C (Solvent evaporates during coating transfer – improved cosmetic and coverage). Design of extraction includes flash-off function. Easy operation via Touch-Panel. Optional transport-systems: Belt-, Pin-chain-, grip-chain-transport with cleaning function. Double-sided coating in one cycle. Minimum wastage of PISM ink compared to any other technology used for SMOBC.

...more

Semi automated UV Exposure Machine

Automated & Semi-automated UV Exposure Machine The fundamental objective of a dry-film laminator is to intimately bond the dry-film resin and the copper surface of the board, avoiding any air entrapment whatsoever. From a physical standpoint, this can only be correctly performed in the moment that the resin reaches the contact point, in a very fluid/gel like status. The high pressure of hot lamination rolls and a sufficient temperature of the board surface, contributes to a successful lamination process. Pits and scratches on the copper surface can then be totally filled with dry-film as shown in below figure. Manual laminators are very close to this ideal lamination condition, since in these machines, the dry-film envelops the hot roll for more than a 1/4 of its circumference, maintaining heat and becoming gel like before coming into contact with the board surface. But generally, in the conventional process, boards are not preheated and therefore, the result is not perfect. Refer below figure FEATURES Very high productivity/quality Tacking and cutting on flight (no stop process) Lamination rolls vibration Very high lamination pressure Adjustable dry-film preheating Excellent board preheating High lamination speed Suitable for inner layer and rigid board

...more

REVERSE ENGINEERING SYSTEM

Reverse-engineering of boards and data Produce PCB fabrication Gerber and drill files from bare boards and / or artwork for PCB design and Legacy re engineering applications. Re-engineering application. ScanCAD has been offering PCB Re-Engineering systems to the marketplace since 1990 and our systems are the leading systems in the world. We offer the only system that can generate all the Gerber data and Drill data to re-manufacture a PCB to the same Form, Fit and Function as the original PCB which eliminates the need for costly and time consuming testing and re-certification. In addition, we also offer additional software modules which can take the data back to schematic or into a CAD package for re-design ScanFAB ScanFAB is a flatbed scanner based re-engineering system that has the capability of scanning PCB's, film, stencils, etc and producing the Gerber data and Drill files necessary to manufacture the PCB. It also contains a full Gerber editor that can be used to modify the Gerber data as necessary The high resolution scanner included with the system is calibrated with a NIST traceable glass plate ensuring an accurate image of the scanned film, stencil or PCB. The color scanning capability of the scanner and the powerful color separation software algorithms in the system permit the fast and easy color separation of images needed to vectorize multilayer PCB’s. The system also includes some powerful raster filter, clean up and editing features to help massage the raster data prior to vectorization. The full FAB product has all of the powerful vectorization functions that have made ScanCAD successful for the past 25 years. The resulting Gerber X data file sets the quality standard in the industry and is the reason why ScanFAB is the most successful and widely used PCB re-engineering system in the world today Fully integrated, stand alone workstation PC-based software integrated with a high-resolution, calibrated image processing unit Reverse-engineering of boards and data FLYING PROBE TESTER ScanINSPECT FPT is a flying probe electrical tester suitable for fixture-less bare PCBs. It can also be used in combination with a grid tester for fault verification or to test nets exceeding test points of a grid tester ScanINSPECT FPT is capable of performing electrical tests on PCBs in many situations such as: Prototypes Samples Small volume production Determination of “golden board” Combination test with a grid tester Fault verification A PCB is tested against a netlist without the need for fixtures. Hence, test can commence immediately after PCB production

...more

Low-pressure plasma cleaning system

Plasma Cleaninf system Low-pressure plasma The innovative surface-treatment technology Clean, reliable Surface cleaning in industry is important for improving coating adhesion. Conventional cleaning methods very quickly reach the limits of their capability and, following wet-chemical cleaning, detergent traces are still found on the surface and even after thorough rinsing and drying are not completely removed. Low-pressure plasma cleaning results in surfaces with zero contamination. Treatment cycles of only a few minutes produce outstanding results with no surface residues. Low-pressure plasma possesses excellent crack penetration. Even intricately shaped parts are perfectly cleaned since the gas readily penetrates minute gaps inaccessible to liquids The decisive factor in the plasma cleaning process is the formation of gaseous and hence volatile products. The plasma constituents react with the organic contaminants and disintegrate into water and carbon dioxide even at room temperature (-CH2-CH2-)n + 3n O2 " 2n CO2 + 2n H2O The reaction products are gaseous and hence easily removable from the reaction chamber.

...more

Pinless Machine

Pinless Optical Registration & Induction Bonding System Pinless Machine is used for aligning inner layer and bonding one over other and thereafter welding by using inductive current. This makes ML production simple The optical registration system gives many benefits, such as No pots etching punching /drilling necessary anymore. No rivets. Process cost reduction : no dedicated tools for inner layer registration and lamination press. Possibility to weld 10mm multilayer thick. If you need any additional information, kindly do let us know.

...more

Pick And Place System

EUROPLACER Europlacer’s Integrated IntelligenceTM is defined by the fact that the Pick and Place machines have been designed to be flexible from the outset. All aspects of the machine architecture (axis configuration, feeder inventory, turret head technology, software control, programming system, etc) have been designed to work together with intelligent feeders in a changing environment - this is truly Integrated IntelligenceTM. As a result, Europlacer Surface Mount machines release usable productivity in day-to-day performance. iineo-II iineo is widely configurable, allowing for 24 different machine possibilities, for the dual head machine: Dual linear motor gantries including two rotary turret heads with 8 or 12 pickup nozzles 2 board positioning mechanisms Oversized board options Feeders in front and rear, or front only The iineo platform features many improvements to the Europlacer machine range, such as an extremely high feeder count, largest industry board size and increased maximum component height. The platform uses Europlacer’s unique Integrated IntelligenceTM plus proven core features: highly robust and flexible turret head intelligent feeders 3DPS powerful software tools

...more

PCB Edge Finishing Machine

PCB Edge Finisher, V Scoring & V Grooving Machines The EdgeCut is incredibly quick, up to 60% faster than the manual methods of de-burring boards. It eliminates inferior and sub-standard results caused by filing or linishing. The EdgeCutdeburrs frame centralising lugs in one pass, leaving a high quality routed edge with no need for futher inspection. The EdgeCut gives the operator total control of depth of cut with its unique micro adjuster and dial indicator. The BevelCut eliminates the inaccuracies in PCB board edge bevelling. The uniqe depth adjustment and variable angle system (between 20 degree and 45 degree) ensures perfect results on every panel. The high speed bevelling tool seamlessly chamfers the most delicate boards without lifting or burring intricate tracking such as gold fingers. The hardened and ground positioning table incorporates the extraction chamber for effective exhaust of dust. Tab Cut Unlike other de-panelling processes which use croppers to free the panel from the scrap (often causing edge de-lamination, component failure or even worse intermittent circuit faults), this process uses high speed routers to precisely remove the webs causing no stress to either the board or components and leaves the cut undetectable. The machine uses a series of adjustable pins, which locate in the slots to ensure the tabs are removed accurately to either populated or unpopulated boards. The new mark II version is easier to use than its predecessor. It now comes in its own mobile, purpose-built cabinet with fully interlocked safety switches and built in hepa-filtered extraction with bagged waste disposal.

...more

Paste Printer

The SP710avi Stencil printer continues to built upon speed print commitment t high performance and reliability with the addition of ADu providing even greater flexiblity and value within the same indusstry leading platform the system has been developed upon the industry award winning SP700 platform the delivers un paralleled performance manging the rigor of high volume

...more

Oil Heating Multi Layer Press

Bürkle‘sMultilam multi daylight laminating system offered in a special package as a stand-alone productive system using the latest state of the art technology. Bürkle‘s robust solid steel machine design with platen guiding system. Thermal oil heating system providing unmatched platen heating uniformity. Includes thermal fluid piping for compact footprint. Automated or manually supported precision indexing Style Transport Loading system providing the ability to transfer heavy tools reliably time after time. No heavy lifting of tooling platens required. State of the Art Computer and Programmable Logic Controller system with Bürkle‘s Process Visualization and Wonder ware Human Machine Graphical Interface. Features: Enclosed Vacuum Chamber Prismatic Vee Guided Platen Ways Spring Loaded Platen Suspension Electrically heated Thermal Oil Hydraulic Pressure system Heating System

...more

Laser Drilling Machine

The ProVia drillers provide the ultimate processing workstation for rigid boards, with high performance beam positioning for rapid point-to-point drilling and routing complex features. Choose a UV-only model, a CO-only model, or the hybrid version with both laser sources. The CO laser is appropriate for high speed drilling, cutting and skiving of dielectrics, while the UV laser is able to machine copper and provide higher process quality in many dielectrics. Whether your application is with glass- and aramid-reinforced epoxies or non-reinforced materials (e.g.resin-coated foil or polyimide), there is a ProVia model to meet your requirements. ProVia Series Integrated laser drilling / cuttingtool for high volume production High performance beam positioning for rapid, accurate panel processing CO 2, UV, and hybrid (UV+CO2) processing Zoom telescope provides continuously variable spot sizes Optional automatic load/unload and slip sheet handling Optional beam homogenizer for flat-top CO2 spots

...more

LASER DIRECT IMAGING SYSTEM

Enabling High Yield Volume Production of Fine- Feature PCBsExposure on all UV, dry or liquid resists Imaging on inner and outer layers, SBU, flex PCBs and solder maskCompatible with Yellow Room environment. The systems feature Orbotech’s patented LSO Technology™ which can image ultra-fine lines down to 8µm. For the FC-BGA/FC-CSP production our field proven system supports SAP and modified versions of SAP processes, while ensuring pitch down to 20µm. For advanced BGA/CSP subtractive production, our system provides throughput of up to 160prints per hour Nuvogo LDI for Mass production.Nuvogo LDI for Mass production. NuvogoTM 800 is a leading Direct Imaging (DI) solution for mass production digital imaging of fine-line HDI, Flex, Rigid-Flex and MLB applications. This cutting-edge system is powered by the new MultiWave Laser Technology™, which simultaneously generates a multi-wavelength laser beam, offering maximum robustness on a vast range of resist types. Based on Orbotech’s field-proven Large Scan Optics (LSO) Technology™, the system is designed for unprecedented throughput of up to 7,000 panels per day, helping to decrease overall cost of ownership while .maintaining optimal quality at high speed

...more

IR High speed curing Ovens

IR High speed curing Ovens for PISM Especially for the final curing of photo imageable soldermask in the worldwide shortes curing time of about 4 minutes. Two installations in production prove the quality of the polymerisation of the soldermask The secret of the super fast final curing process is a unique 2-step-process. The lead time could be reduced from 60-90 minutes to about 4 minutes, i.e. Short lead time for a fast delivery low energy cost per board low requirement of production area fully automatic process newest PLC-control with touch screen operation no condensation residues in the heating chamber capacity increase possible at any time by adding heating modules scaled cost of equipment due to modular construction

...more

Inkjet Printer

Sprint™-120 Ink Jet Legend Printer Featuring innovative DotStream Technology™ and UV LED curing, Sprint 120 delivers high speed and top quality printing for consistent, volume production of advanced legend designs. Benefits Consistent Printing with DotStream Technology™ Precise drop control at high speeds Optimized algorithms for fine text and filled areas Customized print heads for electronics industry challenges and processes Patented nozzle cleaning station Air scrubber for clean printing environment Volume Production with Top Quality Advanced LED-based UV curing on-the-fly High production quality with less passes than previous systems Uniform printing over challenging surfaces Accurate results on features down to 0.5mm Easy and Flexible Operation No screen mask preparation required Intuitive and user-friendly interface for fast set-up Automated data transfer from CAM Pinless alignment for reduced load/unload time Flexibility to print side A-A or A-B

...more

hot air leveling machine

PENTAGAL Chemie und Maschinenbau GmbH HAL : Model PENTA 550 Penta 550 is a vertical hot air leveling system, which is equipped with the latest technology. User-friendly operation is guaranteed by a touch panel. A high-speed PLC allows high operation-speed. Penta 550 possesses the advantages of the Penta-series, such as top quality and longevity, low-priced and simple maintenance, low spare-part costs and user-friendliness. Because of the enclosed housing the production is emission-free. Of course Penta 550 is lead-free capable as well. The external panels are made of stainless steel. The clamp-lift-unit for the pcb-clamp is an electrically controlled, The dipping and exhausting speed is pilot controlled and safe in menu.

...more

FPT systems

This is the smallest configuration , and is generally recommended for ICT and on-board programming applications. It is characterized by a high level of ergonomy, small footprint, easy maintenance , low power consumption and enhanced operator safety. Thanks to its reduced footprint, and compliance with WCM criteria, the system can be easily and successfully integrated in any production environment. Low management costs and high flexibility guaranteed. Compact TK is especially suitable for: parametric and in-circuit tests Functional tests On-board programming Medium-volume and high-mix production Implement distributed test station Non-conveyable boards Features Up to 1536 analog channels Up to 128 hybrid channels (digital channel up to 10 MHz) Up to 6 user power supply units 2-JOB parallel test with standard cabinet 4-JOB parallel test with double cabinet OPENFIX test to identify open pins on digital components and connectors Universal on-board programmer (up to 8 in parallel) Boundary-scan test Self-tes at the module level Receiver with pneumatic upper contrasts Off-line Programming and Repair Stations Barcode and 2D code reading management and automated statistic data collection Automated programming via CAD data import The Pilot 4D V8 represents the latest frontier in flying probe test technology; it is the complete solution for those who want maximum performance: the highest test speed, low to medium volume, test coverage and flexibility, for prototyping, manufacturing, or repairing any type of board. Its vertical architecture is the optimum solution for probing both sides of the UUT simultaneously. Pilot 4D V8 is suitable for: Vectorless and in-circuit tests Programming and functional tests Boundary Scan test Medium/high volumes with automatic loader Highly-integrated prototypes High-mixed products Boards not designed for testing Reverse Engineering and Repair Features and capabilities 8-flying probe tester unit (4 on each side) Vertical architecture to reduce d.u.t. warpage and vibrations. Both top and bottom sides are equipped with power probe, capacitive probe and camera Manual or automatic d.u.t. loading (optional loader/unloader) In-circuit tests, on-board programming, boundary-scan Quick-test test for functional test sequence implementation Fixed channels available (connected manually or via connector) Off-line programming and repair stations Barcode reading capability and 2D; automated collection of statisctical data Automated programming with CAD data import Repair tool: PWMON (net analysis of powered board), thermal scan (temperature monitoring), DES (software to assess the error probability).

...more

Flying Probe Systems

RAPID LINE The RAPID line flying probe test system designed specifically for testing any type of printed circuit board from simple single side circuits, to complex multi layers, inner-layers and ceramics. There are different types of models available with 4 probes and 8 probes systems, completely independent mobile probes, four probes on each board side. Model; S280 comes with 8 probes 4 on each side. Model S220 comes with 4 probes 2 on each side. Thanks to the third generation of linear guide the S280 is able to achieve very high Speed with the maximum accuracy and measurement repeatability: the X and Y axes of the S280 utilize the roller bearings and powerful brushless motors coupled with pre-loaded, high precision ball screws to move the eight measurement probes. S280 is equipped with the new probes generation that can combine with the same probes traditional test (2wire) with Kelvin test (4wire).

...more

film processor

The Colenta IL-PCB Film processor range is a fully automatic “dry to dry” processing system designed for reliable processing of all types of common used PCB films. The processor incorporates a non opposed roller transport system which has been produced to ensure minimal contact with the film emulsion and has a series of intermediate wash water crossovers which safely transfer the film between each stage of processing to produce high quality PCB images requiring the minimum of operator involvement Our Colenta PCB film processors are well established with a proven reputation for quality production, reliable performance and long life operation Standard Features and accessories: Removable flat feed table upgradable on site for higher processing capacity Touch Free detection and area measurement of all material entering the processor Film area based precise replenishment of all chemical solutions Low level monitoring in all processing tank solutions. External filters for DEV / FIX & WASH Filter Change Alert. Automatic Standby and energy saving modes “Work in Progress” monitoring Integrated Replenishment storage tanks with level control Prepared for connection to an external exhaust air facility

...more

Filling Machine

Mass VIA Filling Machine Vacuum Plugging Machine VCP5000-1 Panel is placed inside themachine and vacuum is optionallydrawn inside the chamberdepending on the hole fill requirements Utilizing a similar principle as the hand-held unit, compressed air is used to force the material into a designated head and then through the via holes Depending on factors, such as hole quality and paste rheology, holes up to 1:40 aspect ratio can be filled; the vacuum is not needed for through-holes Cu plated blind vias can be easily filled without any voids utilizing the vacuum Excess material is removed by squeegee system Via Hole Filling VHF 300V w/ a Vacuum function Flexible plugging machine allowing different types of panels and pastes to be processed handles boards at the extreme ends of the board thickness spectrum (up to 350 mil) minimizes consumption and waste of paste (smaller heads can be used) Max. panel size 24” x 30” Thickness range is up to 350 mil thick 480 Volt, 3 Phase power connection, 4 kW The touch panel display allows up to 50 recipes to be stored Head sizes available: 5”-12" Speed of head movement in the X and Y direction Plane Raze Device SV100 Uniform finish with fine surface roughness Superior sanding is achieved by sanding pressure controlled rotation and oscillation head motion Sanding after hole plugging Deburring and dressing after through hole drilling (thick panels Dressing after plating, built-up PCB Dressing and cleaning of stainless press plates Dressing of multilayers

...more

depaneling system

Circut P-series Powered separator blade Separates up to 700mm panels One step separation & finishing Depanels boards with components up to 70mm high Compensates for inconsistent web thickness Hardened & ground blades and guides Separates from 0.5 - 3mm thick panels Precision board edge conditioning Handles intermittent scoring 3mm separator channel Variable speed control Circut M-series Manually operated separator One step separation & finishing Superior micro-board processing Compensates for inconsistent web thickness Depanels boards with components up to 70mm high Accepts boards with component overhang Hardened &groundblades and guides Separates from 0.5 - 3mm thick panels Precision board edge conditioning 3mm separator channel Quick & simple set up

...more

Coordinate Measuring Machine

High Precision Coordinate Scanning and Measuring Machine Measuring of Drilled Holes on PCBs with Scanner Contour Measuring QC5000 Metrology system Matrix CCD camera Optical depth measuring High speed scanner 80mm line camera Up to 1.000.000 features in seconds Contactless laser depth sensor Fully integrated into QC5000 software Depth profile measuring 3D sensor High precision topography measuring High tech diagnostic tools

...more

Control Impedance Testing System

Advance Performance within your reach Scanning TDR Technology Calibrate to National Standard Accurate over a wide range of measurement Powered by a high speed USB Connection Single and Differential Measurement Data Collection and Display Software Statistical Reporting of Result Affordable Price The Zmetrix ST600 Impedance Test System bring a additional hardware and Software feature to the PCB Test market at a very affordable price The ST600 has 1% measurement accuracy calibrate to 25,50,75 and 100 ohm reference airline tracable to national standard

...more

Graphical User Interface RC

stock management

Be first to Rate

Rate ThisOpening Hours