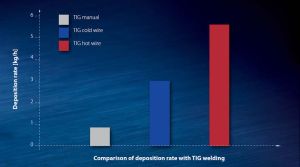

TIG Hot Wire Welding

TIG hot wire welding is a further development of TIG cold wire welding. The welding consumable is heated by a separate power source using resistance heating of the wire stick-out between the contact tip of the hot wire torch and the molten pool. There are many advantages over cold wire welding mainly due to the improved heat balance provided by this process.

...more

Table Rotator

Table Rotator provides accurate and steady rotation for medium to large work pieces. Speed is infinitely variable in various ranges and in both forward and reverse directions. A heavy duty foot pedal controls rotation. Table Rotator allows the welder to rotate the work piece through out 360o reposition for welding positioning. Table Rotator is also used for polishing, painting, metal spray coating etc.

...more

Storage Tanks

Storage Tanks are most commonly used equipment for storing Raw Materials, Intermediates and Finished Products in almost every industry. SIECO will design and supply Storage Tanks, along with MS Platform and Stairs as per process client's requirement

Features : Material of Construction: SS304, SS304L, SS316, SS316L or Carbon Steel Could be with Heating & Cooling arrangement, Flanged or Welded construction with required Nozzles, Manholes and instrumentation as per process need

...more

Storage Tank

Storage Tanks are most commonly used equipment for storing Raw Materials, Intermediates and Finished Products in almost every industry. SIECO will design and supply Storage Tanks, along with MS Platform and Stairs as per process / client's requirement. Sailent Features: Designed and Fabricated as per IS:802, API650, IS:2825 and ASME Sec VIII Div 1 & 2 Codes & Standard Material of Construction: SS304, SS304L, SS316, SS316L or Carbon Steel Could be with Heating & Cooling arrangement, Flanged or Welded construction with required Nozzles, Manholes and instrumentation as per process need Types: Horizontal Cylindrical Dished / Flat Ends, Vertical Cylindrical Dished / Flat Ends, High Capacity Tanks with Flat Bottom & Conical Top Roof

...more

Self Aligning Rotator

Salient Features: Rotators mainly consist of drive, idler, electrical controls Rotators are used for the inside and outside circumferential and longitudinal welding The distance of rollers can be adjusted automatically according to the diameter of workpiece VFS speed control, or a simple gear box drive, as per customer choice. It is stable and precise Rubber, steel or PU wheels customers choice The roller wheel consists of specialized heavy duty tyres made up of 650 dural hardness AC or DC Motor – Ensures constant speed with outer balance loads of 15% Drive system with hi-stress rubber cushion mounts to absorb shock loads and prevent gear box damage.

...more

Self Aligned Rotator:

The Main function of self-aligned welding rotator is to roll work pieces of different sizes without changing the wheel centre, automatically. The welding rotator has two sets of 4 wheels tyres each. One of the wheels that are in contact with the track is driven by the AC or DC Motor for traction. An Electronic device senses the location of the wheels and activates the driving motor, which automatically moves the wheels to the desired set wheel centres. The device is provided with high tech anti-creep control. They are made up of high stress roller cushion tyres of 850 dural hardness, which absorb shock to gearbox and tyre damage. Each section supports the vessel on four points ensuring better traction, and on machines of different capacity. The four wheels of the drive section with clutches are positively driven. This four point suspension is an added advantage when on handling thin walled vessels.

...more

seam welders

Seam welding is resistance welding or roller welding process for joining metal sheets seam joints between two rotating electrode wheels performed using electrical current which is passed through a lid and container. As the metal heats up, the lid is completely joined to the body of the container. Seam Welding is high speed and clean process, which is used when continuous tight weld is required. Seam Welding is mainly used on the seams of tubes and pipes for its ease and accuracy. Seam welding is used to create larger flat-stock parts, join relatively long components, and create cylinders, cones etc.

...more

Pressure Vessels

In some of the chemical reactors, there will be tremendous build up of pressure associated with increase in temperature. Sieco specializes in such pressure vessels of high volume. Sieco has designed and supplied Pressure Vessel for a working pressure of greater than 100 kgcm2 Pressure Vessels are used in Process Industries like including Chemical, Pharmaceuticals, Paint & Coatings, Resin Plants, Biotech industries etc. Our design department will study customer's special process requirements, and then design them. We then manufacture and supply the vessels.

Feature : Designed and Fabricated as per IS:2825, ASME Sec VIII Div 1 & 2, PD 5500 Codes & Standard Material of Construction: SS304, SS304L, SS316, SS316L, Duplex Steel or Carbon Steel

...more

Welding Positioner

Welding Positioner consists of worktable rotation unit and tilting unit. Through worktable elevation, the work piece fixed on the worktable can be placed to ideal position for welding and assembly by the worktable tilting and rotating. To achieve satisfactory welding speed, working table rotating is controlled invariably and continuously with inverter. Welding Positioners align the job to the best position for down hand welding for non circular jobs or for rotating circular jobs.

...more

Mixing High Speed Disperser

Mixers are used in industries like Pharmaceutical, Ayurvedic Medicine, Liquid Mixing, Powder Mixing etc. Multi-shaft mixers are used in Cosmetics & Toiletries, Pharmaceuticals, Food Processing, Chemical Process etc. High Speed Dispersers are most often used in industries like Chemical, Paint & Coating, Ink etc. Mixing / Blending Vessels and High Speed Dispersers can be designed and supplied as per Process / Clients requirement. Mixer / Multi-shaft Mixers are vessels provided with heating and cooling system, temperature control system, electrical control panel etc. Multi-shaft mixers comprise two or more independently driven agitators, low-speed anchor, one or two high-shear devices, and a high speed blade. Dual Shaft is designed for general mixing and dispersion application. It comprises of two-wing anchor agitator and a high speed disperser. Triple Shaft design consists of very high speed disperser which helps the mixer efficiently. High Speed Dispersers consist of driven vertical shaft and high shear disk type blade which creates a radial flow pattern in the mixing vessel, where the blade surface mechanically reduces the solid mass and at the same time disperse them in a liquid used as carrier fluid. High Speed Dispersers are ideal for high viscous application. Sailent Features: Designed and Fabricated as per IS:2825, PD 5500, ASME sec VIII Div 1 & 2 Codes & Standard Materials of Construction: SS304, SS304L, SS316 , SS316L, SS904L, Monel, Inconel, Hastalloy etc Mixing / Blending Vessels and High Speed dispersers are in general identical to Reaction Vessels except for the type of agitators / dispersers Other construction features are identical to Reaction Vessels

...more

High Speed Disperser

Mixers are used in industries like Pharmaceutical, Ayurvedic Medicine, Liquid Mixing, Powder Mixing etc. Multi-shaft mixers are used in Cosmetics & Toiletries, Pharmaceuticals, Food Processing, Chemical Process etc. High Speed Dispersers are most often used in industries like Chemical, Paint & Coating, Ink etc. Mixing Blending Vessels and High Speed Dispersers can be designed and supplied as per Process Clients requirement. Mixer Multi-shaft Mixers are vessels provided with heating and cooling system, temperature control system, electrical control panel etc. Multi-shaft mixers comprise two or more independently driven agitators, low-speed anchor, one or two high-shear devices, and a high speed blade. Dual Shaft is designed for general mixing and dispersion application. It comprises of two-wing anchor agitator and a high speed disperser. Triple Shaft design consists of very high speed disperser which helps the mixer efficiently.

...more

Heat Exchangers

Heat Exchangers are used for change of status of materials, such as liquid to gas and gas to liquid. They are used in majority of Process Industries including Chemical, Pharmaceutical, Paint & Coating, Resin Plants, Biotech industries, Power Plants, Petroleum Industries etc. SIECO designs and supplies Heat Exchangers as per Processes Clients' requirements.

Speciality : Material of Construction: SS304, SS304L, SS316, SS316L, Duplex Steel or Carbon Steel Capacity: Heat Transfer 1m2 - 60 m2 or as per clients requirement Operating range, Pressure � full vacuum to 10 Kg/cm2

...more

Grease Plant

Designed, engineered and fabricated on Tailor made basis to suit individual customer's specifications. Kettles can be designed to work either at Atmospheric type or Autoclave type. Supplied with Conventional double wall jacketed with multiple zones or Limpet Coil for efficient Heat Transfer to suit customers need and preference. Double Motion Counter Rotating Agitator Stirrer Mechanism. The Anchor Stirrer Frame with Scrapers to prevent product build-up on kettle walls and facilitate heat transfer, while the Inner Pitched Paddle Blades rotate in the opposite direction to enable homogeneous Product mixing. Fitted with Single Drive Unit with Spiral Bevel Gear or Two drives with individual Gear Motors. Designed, manufactured, tested and inspected in accordance with the ASME Code Section VIII Division I.

...more

grease kettles

Sieco can design, engineer and manufacture twin motion grease cooking kettles extensively used in the production of lubricating greases. Grease cooking kettles are designed and supplied in all sizes ranging from 1 kl capacity to 24 kl capacity (currently being the largest unit made by sieco). Sieco's kettles are designed for either steam or thermic fluid heating for different capacities. Grease kettles are typically fabricated from carbon steel (sa 516 gr70) or stainless steel depending on application and budget stipulations

...more

Tank Filters

FFilters are designed and supplied as per customers' requirements in material of construction like Carbon Steel, SS304, and SS316 etc. These equipment are customised to suit individual requirement. We supply various types of filter like Online Filters, Tank Filters, Nutsche Filters etc.

Country of Origin : India

Material : Stainless Steel

Shape : Round

Voltage : 110V

Condition : New

Corrosion Resistance : Yes

Finishing : Polished

...more

extractors

different types of extractors are widely used for extraction of natural products like herbs, roots, fruits, oil seeds, and animal glue like gelatine, pharmacy products etc. Sieco will design and supply extractors as per process / client's requirement. sailent features: designed and fabricated as per is:2825, pd 5500 and asme sec viii div 1 & 2 codes & standards material of construction: ss304, ss304l, ss316, ss316l heating / cooling – jacketed / limpet comprises of: required nozzles, manhole, light & sight glasses, insulation and necessary instruments for process controls could be provided with hydraulic actuated discharge system

Feature : Designed and Fabricated as per IS:2825, PD 5500 and ASME Sec VIII Div 1 & 2 Codes & Standards Material of Construction: SS304, SS304L, SS316, SS316L

...more

Dryers

We design and supply dryers as per customers' requirements with material of construction like Carbon Steel, SS304, and SS316 etc. Dryers are widely used in applications such as chemical plants, welding electrode heating, plastic granule drying, card board drying, paint drying, wood processing, clay drying etc. We supply various types of dryers like Spray Dryer and Vacuum Band Dryer. Filters are designed and supplied as per customers' requirements in material of construction like Carbon Steel, SS304, and SS316 etc. These equipment are customised to suit individual requirement. We supply various types of filter like Online Filters, Tank Filters, Nutsche Filters etc.

...more

conventional rotator

The Conventional Welding rotator capacity ranges up to 1500 tons for larger loads and larger diameter range, provided with all Polyurethane wheels with overload disc and all steel wheels according to the capacity. The frame and rotator base is fabricated vigorously to ensure perfect alignment to carry the weight of the vessel / Job. Both the drive and the idler frames are provided with robust fabricated and machined wheel brackets which support the axles and bearings of the rollers Rotators can be used for applications like Pressure Vessels, Heat Exchanges, Boilers, Tanks, Pipe welding etc. More effective and better solutions to cater higher capacity for Nuclear, Generator, ship building etc Fast production and quality improvements Reduce fatigue for welder No need to use crane of job handling

...more

Conventional Rotator:

The Conventional Welding rotator capacity ranges up to 1500 tons for larger loads and larger diameter range, provided with all Polyurethane wheels with overload disc and all steel wheels according to the capacity. The frame and rotator base is fabricated vigorously to ensure perfect alignment to carry the weight of the vessel Job. Both the drive and the idler frames are provided with robust fabricated and machined wheel brackets which support the axles and bearings of the rollers

...more

boom manipulator

SIECO can produce with a wide capacity range from 1.5 mtrs to 6.0 mtrs (60" to 236") strokes. The Column and Boom Manipulators can be used on a wide variety of parts and part shapes.Boom drive that comprise Heavy-Duty Linear Ways and Precision Ball Screw of various sizes and Larger Rack and Pinion Drive, Servo Motor with adjustable speed Column Lift mechanism comprises of Heavy-duty linear ways and Precision Ball screw up to 3.0 mtrs, 4.0 mtrs and larger Double Chain, Sprocket drive with High Efficiency Servo gear motor with adjustable speed drive

...more

Column and Boom Welding Manipulator

SIECO can produce with a wide capacity range from 1.5 mtrs to 6.0 mtrs (60" to 236") strokes. The Column and Boom Manipulators can be used on a wide variety of parts and part shapes. Sieco's standard column and boom manipulators have the following specifications: These manipulators are designed to move a weld head over a weld joint. In order to meet the application requirements, the CBM series is produced in several ranges. SIECO upgrades each axis of the CBM motion as precision welding axis and X-Y drive to a ball screw and nut, driven by a servo motor with encoder feedback. SIECO will also consider your special requests for column and boom manipulators and features as well. The following benefits of standard column and boom manipulator over welding the part manually reduces the time to prepare a part for welding and finish a part after welding. Also, rework time will be reduced and part scrap will be cut. Capable to achieve consistent weld results Capable to maintain weld head over weld joint in a stable position during the weld Increases arc-on time and overall productivity Provides ability to have multi-weld stations using only one weld head, increasing your return on investment Reduced operator fatigue Reduced consumable costs Ability to have two welding process at one welding station by using both ends of the boom Welding is performed using GTAW, PAW, GMAW, FCAW, SAW. To weld in a stable and secure manner, weld head is located to a desired position by the use of Standard Column and Boom Manipulators after which the part is moved during welding to produce high quality welds. The standard boom can be used as a linear welding axis in some GMAW, SAW and FCAW welding, as these weld processes may not require precise welding motion. In case of linear welding desired for GTAW, PAW and Laser welding, we advise to upgrade the boom motion to the precision CBM model. Applications: Storage Tanks, Chemical Tanks, Pipe Manufacturing Industry, Boiler Industry etc Motorized horizontal boom travel, rack and pinion gear drive. Adjustable speed - 25 to 1500 mm/min. (2 to 60 IPM) using AC Motor. (Precision drive uses ball screw with Double nut, with Servo motor with encoder feedback, speed range is 1 to 60 IPM) Motorized boom lift travel, double chain drive. Adjustable speed, 25 to 1500 mm/min. (1 to 60 IPM) (Precision drive uses ball screw and nut, with Servo motor with encode feedback, speed range is 1 to 60 IPM) Safety Device – anti-fall device in case the chain should fail Rotational Base assembly – allows column to be rotated 360 degrees. Includes locking brake with travel Car option, includes manual gear to rotate column Pendent Control – Includes joystick for operator to control up/down and in/out position of manipulator AC Motors drive boom – both horizontally and vertically Limit Switches included to prevent over-travel. Heavy-duty linear Guide ways on boom and column to insure smooth travel in both axis. Horizontal boom travel for some GMAW, FCAW and SAW applications. Boom and Column are machined to insure smooth and accurate travel motion Designed to hold 200 kgs (440 lbs) of total weight on boom, on either end. NOTE: SIECO manipulators are NOT designed as personnel carriers. A seat or operator platform should never be added to the boom, nor should a person ever ride on the boom.

...more

Cnc Plasma Cutting Machine

ULTRA-CUT 300 High Precision Plasma Cutting System Quality Excellent Dross-free Cuts Using Oxygen (O2) Plasma on Mild Steel up to 1 ¼" (35mm) Unmatched Cut Quality on Non-ferrous Materials to 1 ¼" (32mm) with Ar-H2/N2 or up to 1" Using our Unique Water Mist Secondary (WMS) System Ease of Use Fast and Easy Installation Simple Set-up and User-friendly Gas Console Quick-change Consumable Design Easy to identify and troubleshoot problems Productivity Highest Cut Speed in its Class Best Parts Life in the 300 Amp Class Reduced Downtime during Parts Changes with the Revolutionary SpeedLok Cartridge Design of the XT-300 Torch Technology Microprocessor Controlled to Produce the Best Cut Quality on Every Cut Fiber Optic Communication Means less HF Interference Precision Torch Design for the Best Cut Quality in its Class Cuts at an Average of 3 Times Faster than Oxyfuel Reliability Advanced Testing in Lab and Field Trials Ensures Ongoing Performance and Reliability

...more

Chemical Reactors

all chemical processes require reactors of different types and capacities. We, at sieco will discuss with the customers about their specific needs and carryout designing, manufacturing and supplying of chemical reactors with agitators mixers. Sieco's chemical reactors are widely used for chemical process like polymerization, esterification, hydrolysis, hydrogenation and reduction; and cater to industries like resin manufacturing, chemical process plant, paints & coating, pharmaceuticals, biotech industries food and oil industries etc. Sieco can work with any third party inspection for design, construction stage inspection for final documentations. Each sieco reactors with agitators mixers will be designed and built individually according to the requirements of process and customers. We can also meet all ped requirements.

...more

absorption towers

SIECO undertakes turnkey projects services

SIECO undertakes turnkey projects which involve designing, fabrication, supply, installation erection and commissioning of process equipment, piping and welding automation equipment. Our teams of dedicated professionals ensure that the client is satisfied with the services provided.

...more

Turret Lathe Machines Job Work

Be first to Rate

Rate ThisOpening Hours