Seco Cutting Tools

SECO Tools has an established reputation as a leading manufacturer and supplier of carbide cutting tools and associated equipment. SECO can help to increase productivity, reduce costs, improve the supply chains and use the resources the best way possible SECO provide powerful machining solutions to leading companies around the world. Aerospace, Oil & Gas, Energy and Medical industry solutions are, among many others, where SECO deploys highly specialised machining competence. SECO actively contributes to improving productivity and competitiveness in metal cutting machining. Customer closeness and a solution-oriented approach are strategic cornerstones of SECO, together with verifiable and documented improvements in total cost of production. A comprehensive range of cutting tools is another central component of our strategy and the quality and innovation built into our tools is the key to your profitable production. In order to offer the best total solutions we also provide technical support, demonstrations, technical advice, new ideas and practical experience. We Smart Technologies is the Authorised Distributers for the world wide well known Cutting Tool Product. Customer closeness and a solution-oriented approach are strategic cornerstones of SECO, together with verifiable and documented improvements in total cost of production. We work with the same core values of SECO in providing Technical Solution, Understanding Customer Challenges and Improving the Productivity by reducing the cost of production.

...more

high precision components

High Precision machining are the need of the day, but recent advances in technology demand ever higher precision and accuracy in order to reach the desired limit. Technology has been improving the machines and gadgets we use in our day to day life. Starting with the huge gramophones in the olden days from which we used to hear music, today's technology has shrunk the gramophone to a iPod that fits in the palm of your hand. The technological advances have created a need to make things better and better things to be their best. This metamorphism of technology has led to the evolution of machining, pushing it from the level of micro accuracy to the level of Nano accuracy. New generation machines are no longer manually controlled and operated; the computer has taken control over them now. New generation machines are now capable of achieving accuracy levels which were only talked about a decade ago. A part or component is manufactured from its blank stage on various machines to attain its final shape. Machines normally remove material from a blank in order to provide the required shape. Each kind of machine removes material in a specific way to the required dimensions as controlled by the operator of the machine. To achieve all this Knowledge of process planning is prime need and Smart Technologies is very strong in this area. We take up all challenging jobs which require Micro to Nano accuracy.

...more

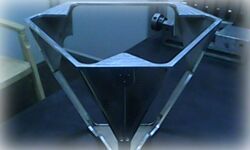

Blow Moulds

Stretch Blow Moulding process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important in products such as bottles for carbonated beverages. There are two distinct stretch blow moulding techniques. In the one-stage process, performs are injection moulded, conditioned to the proper temperature, and blown into containers—all in one continuous process. This technique is most effective in specialty applications, such as wide mouthed jars, where very high production rates are not a requirement. In the two-stage process, performs are injection moulded, stored for a short period of time (typically 1 to 4 days), and blown into containers using a reheat-blow (RHB) machine. Because of the relatively high cost of moulding and RHB equipment, this is the best technique for producing high volume items such as carbonated beverage bottles. We are One of the Largest Stretch Blow Mould Manufacturers in India With the Capability of Making Mould ranging from 40ml to 25 litres. Our Supply chain includes the entire major beverage Industries across India for Water, Carbonated Beverages and Fruit Juices.

...moreBe first to Rate

Rate ThisOpening Hours