Special Applications HSR

300,000 Per Piece

FAR developed different type of self centering steady rests. Such as Self centering steady rests for Milling Machines Self centering steady rests for Screw cutting machined Self centering steady rests for Induction hardening machines Self centering steady rests for Friction welding machines Self centering steady rests with Pneumatic cylinders Steady rests for job feeding on Friction welding machines Steady rests for Shell machining Self centering steady rests for deep hole drilling machines Self centering steady rests for gun drilling machines Self centering steady rests for flute grinding of drill bits. Self centering steady rests for fuel injection parts.

steady rest

100,000 Per unit

1 unit (MOQ)

Best Deals from Steady Rests

Grinding Steady Rest

Get Price Quote

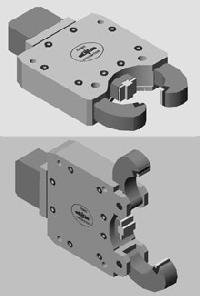

We are the one stop destination in market for availing top grade Grinding Steady Rest. Our Grinding Steady Rest is ideal for holding long slender cylindrical jobs. Our Grinding Steady Rest is suitable for both, CNC and manual grinding machine. Grinding Steady Rest, that we offer, is hydraulically, pneumatically or servo operated. This Grinding Steady Rest is available in side mounted and rear mounted cylinder designs. We make available Grinding Steady Rest that is dimensionally interchangeable with other similar models. Applications Machining of Long Slender ShaftsAutomatic Holding of Jobs In CNC grinding MachinesCrank Shaft ,cam shaft grindingFor any type Grinding Applications Salient Features The Steady Rest Can Be Used For Any Machine Including CNC grinders With a Suitable BracketThe Steady Can Also Be Used As A Traveling Steady Hence No Need Of A Follower RestHigh centering accuracy because real cam technology usedPass through grinding possibleContinues support while part being groundRepeatability Is Within 2 Microns Working principle The steady rest consists of 3 arms assembled in a steel body with carbide pads at the arms for holding the work piece. The centre one brings the other two arms in a circular movement to hold the center of the work piece .This helps to get the repeatability, consistency and centering accuracy. The centre arm is operated by a hydraulic,pneumatic cylinder or servo motor. Types of Steady Rests Hydraulic Self Centering Steady rest with rear mounted cylinderPneumatic Self Centering Steady restSelf Centering Steady rest with servo controlHydraulic Self Centering steady rest for crank shaft grindingHydraulic Self Centering steady rest for cam shaftsHydraulic Self Centering steady rest for vertical loading Standard Range of Grinding Steady Rest are the FollowingModel No.Diameter RangeApplicationsAGU 110 to 30mmFor Normal Grinding Application AGU 220 to 60mmAGUV 110 to 30mmFor Normal Grinding Application with Vertical LoadingAGUV 220 to 60mmACU 1ACUV140 to 70mmFor Crank Shaft Grinding Application with or with Out Vertical LoadingACU 2ACUV245 to 110mm ACU 3ACUV370 to 150mmACU 4ACUV450 to 200mm Note : However, the steady rest can be designed as per customer’s requirement.

self centering steady rest

Get Price Quote

self centering steady rest, Pallet changer, Automatic Deburring Machine

Steadyrest

Get Price Quote

Steadyrest, Barfeeders, self centering steady rest

CNC Steady Rests

Get Price Quote

CNC Steady Rests, Large Rotary Tables, Expanding Collets

steady rest

Get Price Quote

steady rest

steady rest

Get Price Quote

steady rest, Plate Rolling Machine, forging press machine

Hydraulic Steady Rest

Get Price Quote

Hydraulic Steady Rest, bar feeders, Lathe Machine

Hydraulic Steady Rest

Get Price Quote

Hydraulic Steady Rest