Super Finishing Stones and Wheels

As the name suggests these stones are used to achieve very high quality finishes. In certain cases it is an extension of honing operation. We manufacture the widest range of super finishing stones for a vast number of applications. Super finishing stones are manufactured from high purity aluminium oxide and silicon carbide in grits ranging from 500 to 1200 as per FEPA standards. On special requests from our customers we can also supply super finishing stones in grits as per Japanese standards upto grit 6000. These can be supplied in any shape or size. We have developed very special bonds for these products based on the applications, which combine a good rate of stock removal with a capacity to produce excellent finishes. on hardened steel components finishes as high as 0.01 microns can be obtained. These stones are manufactured in vitrified bond, resin bond, rubber bond as well as flexible PVA bond and are recommended based on the application. Application : Our stones are specially manufactured for the following application. Superfinishing the tracks of Ball Bearings (IR & OR) Cylindrical bearings, Cylinder roller and taper bearings, angular and needle bearings Finishing of rollers and shafts, piston pins etc. Finishing of high pressure hydraulic cylinders & pistons Finishing of ball bearing seats of cam shafts & crank shafts. Finishing of shock absorber components. Finishing of Textile and printing rolls. Finishing of bearing shafts of rotary compressor and pumps For super finishing of surface- plain & cup wheels are used for Finishing of cylindrical & conical rollers Engine nozzle pieces Fuel injection pump cylinders Video head drum shaft Pump Impeller Valve seats etc. It is important to select the proper stone or wheel for your specific application. Our experts will help you to decide your requirements. The following basic information will be helpful in making the basic selection Type of machine used and number of stations Stone pressure and oscillation ( wheel speed in case of wheel) RPM of job Approximate time allowed for each operation like roughing stations and finishing stations Material of the component and its hardness Material removal desired Initial finish before super finishing Final finish required Size of the stone and number of stones ( wheel shape & size) Specifications of stones currently being used and the areas in which improvement is desired if any (stone/ wheel) can be mentioned Besides conventional applications, these stones can be used for finishing or polishing on number of components, where a very high quality of surface finish is required. Kindly let us have your specific requirements and our staff will guide you to achieve the best results for your application. Although these are normally rectangular in shape but many special shapes are also being manufactured by us as per the requirements of the customer

...more

rubber bonded grinding wheels

rubber bonded grinding wheels show different characteristics compared to other grinding wheels.they are resilient and as strong as others.these are suitable where coolant is used . The finish obtained with them is high and rich,. They can be used in precision grinding, polishing and regulating. grinding : recommended for precision grinding of steel, 55 hrc and above , in cylindrical and centreless operation under coolant conditions where in higher stock removal and polish are the criteria. cutting : starting fro the thinnest of cutting to deep plunge grooving of metals. They exhibit perfect grinding and polishing in the component. polishing : wheels are flexible, imparting a high accurate finish in microns. The finish obtained under dry conditions are free from scrathes, chatter and score marks. regulating wheels : mainly for centreless machines. Their reilient character in plunge through feed and in form grinding makes it a better product for such applicationa. flute grinding : these wheels are used for grinding flutes of drills and taps. These wheels have high material removal characteristics.

...more

PVA Bonded Products

PVA products are chemically bonded and unlike vitrified or resinoid products. These are very soft and flexible. The structure of these wheels is like a natural sponge and has three dimensional pores. Grades and sizes : The product is available in 46 grit to 400 grit in green silicon carbide but we can supply any grit upto 1200 grit in silicon carbide or aluminium oxide. These are available as grinding wheels, mounted points, honing stones and blocks in size upto 260 mm in diameter. Bigger sizes can be manufactured on request. Usage : These products are mainly used for polishing applications like polishing of watch cases, audio and video heads, printing rolls, cylinders, compressor parts, surgical equipment, vehicle rims, tools and auto parts, dies & moulds etc. PVA products can polish any material ferrous or non-ferrous, metal or non-metal. Some examples are stainless steel, brass, steels, copper, aluminium, bronze, glass, stones etc. Besides polishing, these products can be used for burr removal, descaling, rust removing and for any such applications.One can achieve finishes as high as 0.03 micron on steel components. Basically a mirror finish can be easily obtained with these products. Equipment : No special machines are required to use PVA wheels. The whels can be used with all conventional machines like bench grinders, electric hand grinders, surface grinders, cylindrical grinders, tool and cutting grinders, etc. The wheel is flexible and hence can be easily dressed with conventional dressing tools or even by a used piece of a vitrified grinding wheels. It can be dressed to any desired shape easily. These products are used mainly for polishing and as such too much of material removal cannot be expected. For burr- removal coarse abrasives can be used Limitations : Due to its flexible nature the maximum operating speed is 25 mps Wheels are hydrophilic in nature , hence absorbs moisture and stops cutting. No coolant is required. Storage should be in polythene bags and at dry place. In cas of efficiency going down due to moisture absorption, the wheels can be dried in sun for an hour or so or can be dried in oven at 45 deg. C for about an hour for regaining its original properties. For fine finished, some wax or a drop or two of oil can be applied to the cutting surface. How to use : The wheels should be mounted on the conventional machine. The flanges should be 2/3 rd the wheel diameter. In case of mounted points, conventional electric grinder can be used. After mounting, the wheels should be dressed to required shape and then some wax or wax based compound or oil can be applied to wheels, if fine finish is required. For burr- removal , descaling etc., nothing is to be applied. After polishing the component with the wheel, the same can be buffed using a cloth wheel if mirror finish is required

...more

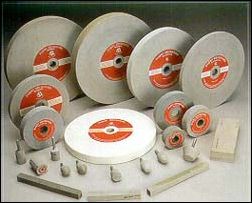

Mounted Wheels And Points

As the name suggests these are small grinding wheels mounted to steel shanks and are primarily used on portable hand grinding machine and clamped in position by means of a collet. They are ideal small tools both for coarse, heavy duty work and for superfine grinding work on precision parts. Super Abrasives can supply all types of mounted points internationally standardized in the shapes A, B and W A = Non Cylindrical mounted points, 6mm shank diameter B = Non Cylindrical mounted points, 3mm shank diameterW = Cylindrical mounted points Besides those mentioned we manufacture special wheels and shapes mounted on threaded shanks based on your specifications and design. How to order Shape: Specify the shape a number like A11, B141, W235, etc.Shank and Length: Standard dia is 3 or 6 mm and length 40 mm. Any other dia and length can be supplied against order. How to order Shape: Specify the shape a number like A11, B141, W235, etc.Shank and Length: Standard dia is 3 or 6 mm and length 40 mm. Any other dia and length can be supplied against order.

...more

Internal Grinding Wheels

These are small grinding wheels which are used for grinding internal surfaces. We have developed very special wheels for the following applications: Grinding of inner and outer faces of Ball & Roller Bearings. Grinding of Bores of inner rings. Grinding of Hydraulic and Pneumatic cylinders. Grinding of connecting rod ends in the automobile industry Grinding of Gun Barrels. Grinding of Gear bores, collets etc. The applications listedd call for high accuracy to the tune of microns, conventional grinding wheels are unable to give such accuracy due to their uneven wear while grinding. We have developed a special bond system which gives the wheel, the most important property of shape retention.For grinding the tracks of ball bearing races the wheels are sulphur treated to provide cool cutting even at very high speeds of 80 mps. Mixed Aluminum Oxide wheels are manufactured to give properties lying in between the two extremes of higher material removal and longer life.

...more

Honing Stones

Honing stones are manufactured from high purity synthetic corundum (Aluminum Oxide) and Silicon Carbide. We manufacture vitrified bonded as well as Bakelite bonded, resin bonded, rubber bonded and PVA bonded honing stones depending on the special applications of our customers. We have developed special cool cutting bonds which provide high rate of stock removal with a good finish. This cuts the production costs and eliminates frequent dressing due to the self dressing property of our stones. The grit range is from 20 to 400 as per FEPA standards and sizes are customised. Applications : Our stones are suitable for most applications requiring Honing and are used in honing Hydraulic and pneumatic cylinder Cylinder Blocks and liners Hydraulic equipment Gears Nozzles Pneumatic Tools Gun barrels of field guns and battle tanks Connecting rod ends Guages Bushes and bores Our Honing stones are made under strict quality control for the specific need of a specific application. Selection : It is important to select the right stone for your application. If you need our assistance, please provide us with the following initial information Type of machine used and number of stones in a set. Machine parameters like pressure, speed of rotation and reciprocation. Size and material of component and its hardness Desired material removal Initial finish before honing Final finish required Size of honing stones Specification of the presently used stone-if any and the areas in which the improvement is required. The grit ranges from 46 to 400 as per FEPA. Stones can be supplied upto 800 as per JIS on request from customers. These are available in rectangular cross section and can be supplied in any required shape.

...more

Grinding Wheels

The art of producing high quality abrasives products consists in finding out the correct composition of raw materials, combined with correct production procedure for every individual applications. The raw materials used are Aluminum Oxide (brown, pink, white & SA ) and Silicon Carbide ( black & green ).The most important part of the grinding wheel is the vitrified bond which joins the grains. We use various types of bonds specially developed for each operation of grinding and manufacture wheels upto 500mm in diameter for centerless grinding ,surface grinding and cylindrical grinding. We have also developed special cool cutting bonds for use on work pieces like drills, milling cutters ,saws, gears, thread grinding etc, where cutting quality & low heat generation are specially important . Special fine grit wheels for fine polishing on various materials before buffing ,have been developed by us . Our range of these wheels are in grits 320 to 1200 as per FEPA standards. Our range comprise of wheels for : Rough grinding Precision grinding Cutting of metal Cutting of ceramic Cutting of glass Cutting of stone Cutting of any other ferrous or non ferrous materials.

...more

conventional grinding wheels

Vitrified Specialities There are a number of products which are specially developed by us for a variety of jobs which cannot be done using conventional grinding wheels or honing stones.Very special bonds have been developed for these special applications. Diamond/ CBN wheel dressing sticks : Specially developed for dressing of Diamond and CBN wheels. These sticks can achieve a quick dressing without damaging the Diamond or CBN. These are specially developed for metal bonded diamond and CBn and for electroplated diamonds. The hardness and the grit size of the stick depends on the grit size of the diamond or CBN to be dressed. Super Alo : Manufactured from high purity (99.9%) synthetic corundum, these are used mainly by mechanics because of their uniform hardness, wear resistance and edge retention propoerties. These stones are most suitable for jobs encountered in workshops like sharpening or finishing of tols of metal working, wood working and plastic. These are used for refinishing of tempered steel where normal files cannot be used. Thease are available in coarse, medium & fine categories and are used wet with water, oil or petroleum products. Super SiC : These are rubbing stones with high cutting efficiency made with silicon carbide. These are best suited for applications where a rapid metal removal is required or softer cutting action than super Alo is required. These are used for sharpening of carbide tools, glass, marble, granite, gem stones etc. These are available in coarse, medium, and fine categories and can be used dry or wet with water , oil or petroleum products. Rectangular stones : For sharpening of lathe tools, planes, scrapers etc. these are available in many standard sizes. Combination stones : are rectangular stones with one side coarse for sharpening hand tools and other side fine for re-sharpening.Rough or medium size is used for grinding while fine for r-sharpening. Slip stones : These are suitable for sharpening and finishing of tools of various forms. Finished sticks : These are available in square, triangular, round and half round cross section for finishing tools, dies and moulds. Available in coarse, medium and fine gracing Knife edge : Sharpened stones for sharpening sharp corners Segments : Available in a variety of standard shapes and sizes. These can be readily mounted on vertical spindle surface grinders with minimum of down time. In addition to these any special shape and size can be provided on request.

Type : Â Specifications

...more

grinding

Be first to Rate

Rate ThisOpening Hours