Thermography Services

Get Price Quote

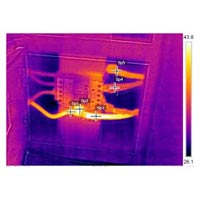

Smart Vision Infrared Thermography SMART VISION has provided infrared thermography in UAE, Oman, Qatar, Saudi Arabia and Bahrain since 2015. This specialized inspection and data-gathering method has been a used for various applications. The combination of expertise in all of these fields has allowed SMART VISION to provide complementary data for applications such as building inspections, Electrical & Mechanical inspections, Research & science, industrial processes, VOC leak detections, SF6 leak detections, Furnace inspections & many more. SMART VISION infrared technicians are trained to Level I & II industry standards, and our additional in house mentoring and training system ensures that expertise, best practices, and application knowledge are shared and continually developed. What is Infrared Thermography? Infrared thermography is the science of acquisition and analysis of thermal information from non-contact thermal imaging devices. Thermal imaging devices are portable and handheld, and the Thermogram / images can both be interpreted on-site as well as loaded into software for additional analysis and formal reporting. Thermography is a very powerful detection and diagnosis tool for troubleshooting, predictive and preventative maintenance programs, and vanguard data gathering complementing other disciplines. A thermographic or infrared survey is a well-established non-destructive testing method that provides a real-time analysis of an object’s apparent temperature gradient. Thermographic imaging systems observe the infrared radiation emitted from the object’s surface to identify thermal anomalies and calculate precise temperatures. Since everything around us is constantly losing heat to the atmosphere in the form of this invisible infrared radiation, the inspection applications are only limited by the imagination. What is thermography typically used for? Identifying problem areas in electrical and mechanical systems Analyzing building envelopes and membrane systems Troubleshooting industrial process and storage systems Specialized utility locates such as in floor heating systems Furnace and boiler refractory surveys Research and development data collection SMART VISION has also used infrared technology for projects such as manufacturing, wildlife studies, veterinarian imaging, aircraft structure analysis, alloy temperature measurement in structures such as flare tips, VOC leak detections, SF6 leak detections and power turbines, and other unique applications. Our images have been used for studies and education material. What Benefits Doesthermography Bring? Scans are typically performed during normal operating conditions and do not interrupt processes Real-time operating data can be collected and analyzed to troubleshoot systems Scans can be performed before and after basic repairs to electrical and mechanical systems to prevent failures and unplanned outages, often during the same visit Problem areas are often quickly identified and narrowed down to minimize further investigative costs including destructive testing and downtime Qualitative and quantitative baselines can be set to monitor ongoing performance of systems Facility insurance and maintenance costs can be reduced through regular infrared monitoring Thermography Electrical Mechanical Civil Furnace Application

Thermography Audit Services

Get Price Quote

Thermography Audit : The goal of every electrical infrared (thermal) inspection is to survey designated electrical equipment in order to pinpoint defective components and elevated temperatures within your power distribution system. lf unfound or untreated these thermal "hot spots" can cause- potential fire, explosion, or electrical service interruption threats. Thermal hot spots are typically caused by unbalanced or overloaded electrical circuits, loose connections, or broken equipment. These conditions are often overlooked during routine evaluations of facilities and can result in the release of heat that will be visible only through infrared thermography detection services. Benefits : Mai tai on the integrity of your facility's electrical system Reduces electrical fire hazards Provide uninterrupted power to tenants/ clients employees Detect faulty connections/overloaded circu its Provide a snap shot in time of the condition of your mechanical systems, motors, bearings, etc. Preventative or predictive maintenance programs save money by reducing : Premature equipment failure Emergency overtime Overnight shipment of part Insurance premiums : (many insurance companies give discounts for performing regular infrared inspections) loss of revenue due to downtime

Looking for Thermography Services Providers

Thermography Services

Get Price Quote

Thermography Services, Air Circuit Breakers, Vacuum Circuit Breakers

Thermography For Cold Storage

Get Price Quote

Thermography For Cold Storage, Address Verification service

infrared thermography audit

Get Price Quote

infrared thermography audit, Power Quality audit, Electrical Safety Audit

Thermography Surveys

Get Price Quote

Thermography Surveys