tilt table

Get Price Quote

1 Piece (MOQ)

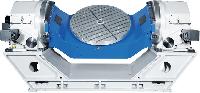

CNC Rotary Tilting Tables

Get Price Quote

ERT series of Rotary Tilting Tables enables accurate and productive machining. These tables are designed so that the surface of the table top is on the center line of the tilting axis, for a greater piece part capacity, easier programming and less interference in the work zone.

Best Deals from Tilting Table

Mild Steel Tilting Table

Get Price Quote

1 Piece (MOQ)

NC Tilting Rotary Table

Get Price Quote

Pneumatic Clamping system, with built-in patented disk-clamping design (Taiwan PAT.: 217736) to ensure cutting endurance. The feature of wear resistant alloy Dual-Lead Worm Gear is high mechanical efficiency of power transmission, high indexing accuracy and easy adjusted on the backlash. Able to be connected with CNC machine to perform synchronous 5th axis multi-angle machining. Able to be connected with CNC machine to perform tilting angle machine (4+1 axis) through Single Axis Controller. Minimum Indexing Degree: 0.001° Tilting range: +/- 110 °

tilting table

Get Price Quote

Features: PneumaticHydraulic Clamping Pre-Loaded Axial Radial Roller Bearing Dual Lead Worm Gear set

tilting table

Get Price Quote

In a Deep Tilting Rotary Tables the Swing Diameter is larger as compared to the Turn Table Diameter to accommodate larger diameter component on to a smaller table. Features Hydraulic Clamping Pre-Loaded Axial Radial Roller Bearing High Grade C I Construction Dual Lead Worm Gear set

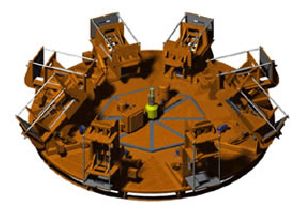

Tilt Pour Rotary Table

Get Price Quote

The Rotary Casting Machine advances permanent mold casting technology another step and makes it the most profitable approach for the modern foundries today. This high production, completely automated system can meet your needs for large volume applications. We incorporate up to 12 of our standard casting machines (#2H, #3HS, #6H or RT machines) on one rotary table to reduce cycle time in each station to as little as 20 seconds. As an example, based on our 8-station 2H Rotary Table, we have calculated that eight seconds is necessary to index the table between stations without inertial forces affecting feed characteristics of castings. Assuming a three minute (180 second) cooling cycle, this rotary system will theoretically produce 120 cycles per hour. At 83% of theoretical, it would be 100 machine cycles per hour. At 100 hours per week, this calculates out to 10,000 machine cycles per week. If there are two cavities, it will produce 20,000 parts week . This will give a total production of nearly one million parts per year!

cnc tilting rotary tables

Get Price Quote

cnc tilting rotary tables, cnc rotary tables, Rotary Table

nc tilting rotary tables

Get Price Quote

nc tilting rotary tables, index tables, Linear Bearings, Linear Slides

Universal Tilting Rotary Table

Get Price Quote

Universal Tilting Rotary Table, machinery loans, Jaw Compensation Chucks