EI28 10P Horizontal Linear Transformer

60 - 70 Per Piece

1000 Piece (MOQ)

Notes RoHS 3 compliance is available on most products, subject to our confirmation. Specifications subject to change without notice.

transformer laminations

Get Price Quote

long standing association in the market, we are offering an extensive array of transformer laminations and strips. These laminations and strips. These products are remarkably efficient in performance and ensure long lasting service life.

Best Deals from Transformers

Transformer Oil Filtration Machine

Get Price Quote

1 Piece (MOQ)

Isolation Transformers

Get Price Quote

Key Features . High efficiency, high reliability and accuracy. Compact, rugged in construction, free standing, floor mounting model and housed in sturdy metal casing with sufficient ventilations . Double wound with copper conductor with low coupling capacitance to isolate the voltage spikes and noise from the mains . High insulation values . Suitable for use with modern sophisticated micro processor based equipment, CNC machines, computers and other Industrial processing . To withstand the ambient temperature up to 55 centigrade and 95% humidity

Transformer Oil

59 Per Litre

210 Litre (MOQ)

CRGO Transformer Cores

Get Price Quote

The Slitting Machine gives 18 adjustable strip widths. Tool geometry is of critical importance for eliminating burrs of CRGO. CUTTING ACCORDING TO LENGTH (CRGO) AUTOMATIC METHOD OF PROCESSING CRGO POWER TRANSFORMER LAMINATION Evergreen uses the newest, computerized version of Cut to Length Machines in order to produce Step Lap Transformer Laminations Cores. MANUAL METHOD USED FOR DISTRUBUTION CRGO TRANSFORMER LAMINATION. The SECOND stage of the CRGO Lamination manufacturing process is "Shearing" at 45 or 90 as required by the customer. Strict tolerances are maintained (as per the tolerance chart) and a unique three point location method ensures accuracy in dimensions in terms of angle and length. Burs are controlled by ensuring the blades are always sharp. Continuous line inspection ensures all parameters are strictly maintained within acceptable limits. The THIRD step of CRGO Lamination manufacturing process is to fabricate "V-Notch" or holes at per customer's design. Accuracy is utmost importance and specially designed jigs and fixtures ensure that all dimensional tolerances specified by the customer are maintained. STRESS RELIEF ANNEALING The FOURTH step of the manufacturing process of CRGO Transformer Lamination is to deburr and stress relief anneal the material by other health annealing furnace. This is done as per the mill's specification at 820 º C for a few minutes depending upon the thickness and grade of CRGO material. TESTING Final Inspection of CRGO Lamination for Manufacturing Tolerences as per International Standard OR as Per Customer Requirement. Checking of Core Losses on the Finished CRGO Lamination and No Load losses on CRGO Built Up Cores. Issue a Test Certificate for Every Despatch. PACKING We are able to deliver CRGO lamination as leg or sheet packet, according to your packing requirements, inside of wooden box or on the pallets. Production Processes For Crgo (Grain Oriented Steel) Toroidal Transformer Cores SLITTING CRGO Electrical steel comes in the form of wide coils having widths of 750 mm to 1000 mm. These coils are to be slit in various widths in steps ranging from 10 mm to 100 mm. WINDING These slit coils of CRGO are wound on semi automatic winding machine as per the dimensions given by our customers. SPOT WELDING On winding the CRGO Toroidal cores to the exact size the start and finished ends of the core are spot welded on spot welding machine. STRESS RELIEF ANNEALING During the winding process of CRGO, severe stresses are induced in the gains of the raw material. Theses stresses are relieved in our specially designed annealing furnace equipped with automatic temperature controller, circulating fan and inert atmosphere. The annealing cycle (at 800°C) improperly controlled to get uniform and best annealing results. TESTING Since the CRGO electrical properties of cores are very critical, every core is tested on a specially designed test bench. The ampere turns/cm (magnetization current) are measured on every core to ensure that they are within the specified limits. PAINTING After testing the 'PASSED' cores are painted with N.C. paint to prevent the CRGO Toroidal cores from corrosion. PACKING The Electrical Properties of CRGO Toroidal cores are very sensitive to bad handling during transit. We take great care while packing the cores in wooden boxes with cushioning material to prevent stresses on the cores during dispatch.

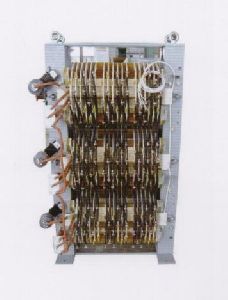

Sockets Control Transformer

Get Price Quote

Safety Double Wound shell type safety isolating Transformers . Winding: Continuously rated double wound with an earthed screen between Primary and secondary windings. Output windings on Single phase units are center tapped to earth whilst in three phase units, the star point is earthed for safety.

volt coil

Get Price Quote

CRGO Steel Rectangular Core

Get Price Quote

High Voltage Rectifier Transformer

Get Price Quote

Transformer Core

Get Price Quote

We supply all types of transformer cores and laminations for all types of applications. We give best quality and services

Crgo Lamination

Get Price Quote

Core manufacturers in india, transformer lamination manufacturer, c.r.g.o lamination manufacturer, step lap core manufacturer, transformers stamping manufacturer, crgo lamination manufacturers.

Siet Neon Transformer

Get Price Quote

High voltage electromechanical transformer (1.000÷15.000V) with operating current up to 200mA.Thanks to the advanced production system and to its metal box design, Siet Neon Transformer can work 24 hour per days in the most severe atmospheric conditions (IP44) without needing any additional enclosure.The transformer is provided with Safety Knife Switch and housing for PVC conduits under the lid. Dimmable using Dimmer-box or the most known dimming systems in leading edge or forwarding phase control.Benefits with Siet Neon Transformer Metal Box:• Protects the resin against atmospheric agents• Contains thermal dilatations of the resin, which are cause of dangerous cracks• It is good heat conductor and ensures an efficient dissipation, keeping low temperatures on the terminal board where electric connections and protection devices are located• It ensures an excellent protection for operator or technician• It protects against electromagnetic disturbances• It ensures a ground connecting case, that is a characteristic required by the most international standard

High Frequency Transformer

Get Price Quote

High Frequency Transformer, Amorphous Transformer, Coils

transformer strips

Get Price Quote

transformer strips, Die Cast Rotors, electrical motor stamping

ac transformer

Get Price Quote

ac transformer, Smps Transformer, ac transformer, AVR Voltage Stabilizer

dc transformer

Get Price Quote

dc transformer, ac transformer, Inverter, Transformers, Current Transformer

high current bushing

Get Price Quote

high current bushing, Transformer Bushing, Current Transformer

ferrite transformers

Get Price Quote

ferrite transformers, ferrite inductors

Transformer Oils

Get Price Quote

Transformer Oils, Paraffin Wax, Bee Wax, Chlorinated Paraffin Wax