commutator turning machine

Get Price Quote

Turning Machine

Get Price Quote

Acemicromatic, a leader in IoT-driven manufacturing solutions, offers advanced CNC turning machines that integrate IoT technology to optimize performance and precision. These machines are equipped with real-time monitoring capabilities, allowing manufacturers to track machine health, predict maintenance needs, and ensure consistent production quality.

Best Deals from Turing Machine

Cnc Turning Machine

Get Price Quote

Two Axis Turning Center

Get Price Quote

We are offering Super Jobber is the largest model in Jobber family. It is provided with a robust A2-6 spindle and higher power suitable for machining large size components. This model is available with 400 and 500mm admit between centers. Options of either linear motion or box type guide ways offer the highest flexibility.Please contact Ace Designers for more details.

vertical turning machine

100 - 1,000 Per

Appreciated for offering high quality turning, our CNC Vertical Turning Machine is highly efficient. Use of superior quality raw materials in the production ensures excellent performance of Vertical Type Turning Machine. We stand among the leading Vertical Turning Machinery Manufacturers in India.

polygon turning machine

17 - 18 Per

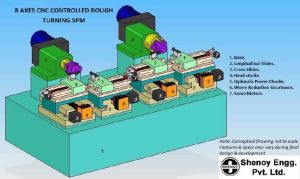

Turning SPM

Get Price Quote

Features & Specs: A twin station concept – one station to bore and face the front end of the job, the other to bore and face the rear end of the job. Each station has 2 sets of compound slides with servo driven cross and longitudinal axes. One set of compound slide does facing while the other will be used to bore. Both the facing and boring slides will work simultaneously to reduce the cycle time. Slides made of male, heavy duty, extra rigid, case hardened guideway strips and female turcite lining. Many innovative design features for reducing the cost, without diluting the stock removal capabilities within the specified time. Sequence of operation: Manually load cast job onto left hand chuck & on the auto-cycle button. Job gets clamped automatically & head stock starts rotating Machining of the face & ID of the front end of the job takes place. While machining on LH station is going on, operator loads an ID machined job on RH station. On the auto-cycle button & rear side machining of the job takes place in the RH station. Cycle Time: Every 75 seconds, one rough turned component is achieved. Conclusion: The customer is now getting a rough turned component at the rate of 1 piece/75 seconds, compared to the earlier 1 piece/10 minutes. i.e. a cycle time reduction of 87.5% A comparatively less accurate, highly affordable, Stock Turning CNC SPM is expected to result in elimination of 8 high end, accurate, expensive CNC turning centers, which are hitherto used for rough turning operations. Reduction in man power – 8 CNC operators along with 8 turning centers are now available for more gainful work. Increased output. After rough turning in our machine, finish turning is carried out on CNC tuning centers, thereby cutting down the whole cycle time from 1 piece/12 minutes to 1 piece/3.25 minutes. i.e. a cycle time reduction of around 73%.

CNC Turning Machine (Model No : PN150BBC)

Get Price Quote

The company is a major Manufacturer, Exporter and Supplier of CNC Turning Machine (Model No : PN150BBC) in Bangalore (India). The CNC Turning Machine (Model No : PN150BBC) is widely demanded across the globe owing to its unsurpassed quality and excellent performance. The company offers the best quality CNC Turning Machine (Model No : PN150BBC) to the clients. Features Of CNC Turning Machine (Model No : PN150BBC) : Semi automated & low cost for pipe up to 12� Male & Female machining Exclusively for casing pipes CNC turning centre LM Guideway/Hardened Guideway Bigger bore with manual collet type Z-375 mm x-150 mm diameter & bore Bore Sizes For CNC Turning Machine (Model No : PN150BBC) : 225 330 400

polygon turning machine

Get Price Quote

Hydraulic Copy lathe machine, Turning Groove machine

Get Price Quote

Features This Hydraulic Copy lathe & Turning Groove model is a unique turning tool copy lathe. Its distinguishing feature is that it doesn’t need to have a molding tool produced in advance, but rather just provide the wood article or copy shape sheet and cutter, and then reap the finished products, saving on time and costs by eliminating the need for tool production. It is suitable for various items in small quantities, or large quantity wood working processing that required changing the shape of the article at any time. The machine peels with linear slide tracks and is installed with an electric force auto grease system to enhance the machine’s capacity and life. Peeling operation is performed with electric PLC and hydraulic tower controller. It could enhances the machine’s flexibility and stability while in operation. The machine employs a dust-proof electrical system. The hopper feeder is hydraulic operated, while the tailstock center is hydraulically operated to clamp the workpiece. A guide ring supports the workpiece firmly while cutting to ensure the maximum stability and accuracy of operation. Equipped with three sets of cutters for cutting any complicated profile, a half round cutter & “U” type cuts for rough cutting, an there is a “V” type cutter for finish cutting. Equipped with two sets of right-angle cutter rests w/hydraulic auto control. Precision ball screw system for transmitting replacements of hydraulic cylinder.

CNC 4-Axis Flash Turning Machine For Piston Rods

Get Price Quote

We offer cnc 4-axis flash turning machine for piston rods. This machine built with 8 station turret head and sliding spindle head accommodates piston rod of length up to 1400 mm

vertical turning machine

Get Price Quote

We offer Vertical Turning Machine. Maximum efficiency in shaft production – with the VT series of turning machines VT 2-4 – The turning machine for vertical 4-axis shaft machining Where shaft machining involves large numbers of workpieces, the first choice must be the VT series of turning machines. In the machining of shafts on turning machines the focus is on the speed of the process, whereby both loading / unloading and the machining cycle need to be very fast. This optimal requirement is fulfilled with the VT 2-4 turning machines. Four axes, short travels, powerful mainspindle – these are the strengths of the VT 2-4 turning machines. The full impact can be best felt where the component batches are large. Of decisive importance in the use of these turning machines is the “two-sided” machining process, which massively reduces the machining time on the VT 2-4 turning machine. Flexibility is guaranteed with the use of two tool turrets with eleven stations each, all of which can be equipped with turning tools and driven tools. Automation is fully integrated on these turning machines. On the VT 2-4 turning machines it is the turret that does the loading and unloading. Whilst one gripper (in the turret) conveys a new raw-part into the turning machine, the other one removes the finish-machined component, with the whole process taking just 6 seconds. Technical Data Chuck dia. mm 160 Workpiece dia., max mm 63 Workpiece length, max mm 400 X-axis travel mm 340 Z-axis travel mm 625

Cnc Turning Machine

Get Price Quote

Model Units LT-16-300-LM Capacity Swing Over Bed mm 450 Swing over carriage mm 225 Maximum Turning Dia mm 320 Maximum Turning Length mm 300 Distance between centres mm 296 Spindle Spindle Size Nose A2-5 Max.Bar Capacity mm 25* Bore through Spindle mm 52.5

cnc vertical turning machine

Get Price Quote

cnc vertical turning machine, Cnc Vertical Lathe Machine

Vertical Cnc Turning Machine

Get Price Quote

Vertical Cnc Turning Machine, cnc turning centers, Vertical Turning Lathe

polygon turning machine

Get Price Quote

polygon turning machine, Jigs, U Drilling Machine, Honing Machine

Turning Machine

Get Price Quote

Turning Machine, Tapping Machines, Drilling Machine

Cnc Turning Machine

Get Price Quote

Cnc Turning Machine, turn mill center

turning machinery

Get Price Quote

turning machinery, Grinding Machinery

Cnc Turning Machine

Get Price Quote

Cnc Turning Machine, Precision Turned Component