Vacuum Heat Treatment Furnace

200,000 Per Piece

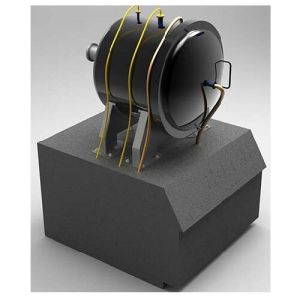

Horizontal Vacuum Heat treatment Furnace

Get Price Quote

The Advanced Horizontal Vacuum Heat treatment Furnace used for Hardening, Annealing and Brazing applications. The operating temperature is 1750 degree C. And the charge weight is up to 500 Kg. This furnace has the coolig facilitity of forced cooling by canned motor, blower and heat exchanger.

Best Deals from Vacuum Furnace

Vacuum Furnace

Get Price Quote

Vacuum furnaces are preferred over conventional methods of heat treatment such as salt bath furnaces and controlled atmosphere furnaces due to the advantages it brings - such as prevention of surface oxidation, decarburization and low distortions on work pieces thus resulting in cleaner surfaces, less rework and less post-heat treatment cleaning or corrective operations.

Vacuum Furnace

Get Price Quote

INDVAC has designed and supplied various size of Vacuum Furnaces for special applications like, Vacuum Brazing, Annealing, Hardening, Tempering, etc. meeting to the customer requirements. INDVAC and Products are worldwide recognized for manufacturing and supplying superb quality Vacuum Furnaces. Our Industrial Vacuum Furnaces are made using the genuine raw material in order to meet international standards of high performance. These Pressure Vacuum Furnaces contain advanced features making them widely adaptable to cater to various requirements of customers.

Vacuum Furnace

Get Price Quote

Vacuum furnace has proven its mettle as a leading Vacuum Furnace manufacturer, manufacturing state-of-the-art Vacuum Furnaces for the automobile, electronics and aerospace industries at the most economical prices.

Vacuum Furnace

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. The Vacuum Heat Treatment Furnace Group provides advanced, energy-efficient and environmentally friendly vacuum heat treatment equipment with guaranteed process technology. Our vacuum furnaces are used in applications for annealing, brazing, sintering, gas quench (High Pressure Gas Quenching), vacuum oil quench, vacuum carburizing and nitriding (Low Pressure Carburizing, PreNit high speed vacuum carburizing), along with a wide variety of custom engineered process technologies.

Vacuum Heat Furnace

6,500,000 Per unit

Vacuum Brazing Furnace

Get Price Quote

Vacuum Brazing Furnace, vacuum hardening furnace, Vacuum Sintering Furnace

vaccum furnace

4,000,000 Per Piece

vacuum furnaces

Get Price Quote

Vacuum furnaces are preferred over conventional methods of heat treatment such as salt bath furnaces and controlled atmosphere furnaces due to the advantages it brings - such as prevention of surface oxidation, decarburization and low distortions on work pieces thus resulting in cleaner surfaces, less rework and less post-heat treatment cleaning or corrective operations.

vacuum furnaces

Get Price Quote

We are an eminent and leading trader of Vacuum Furnaces

High Temperature High Vacuum Furnace

Get Price Quote

High Temperature High Vacuum Furnace, KF Clamps, diffusion pump

vacuum furnaces

Get Price Quote

Vacuum furnaces are preferred over conventional methods of heat treatment such as salt bath furnaces and controlled atmosphere furnaces due to the advantages it brings - such as prevention of surface oxidation, decarburization and low distortions on work pieces thus resulting in cleaner surfaces, less rework and less post-heat treatment cleaning or corrective operations.

Vacuum Annealing Furnaces

Get Price Quote

Vacuum Annealing Furnaces, air circulating oven, Furnace Maintenance Services