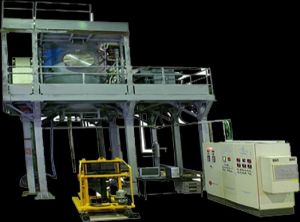

Multi-processes CVD CVI vacuum furnace

Get Price Quote

Carbon fibre reinforced composites with a matrix of carbon or silicon carbide have excellent characteristics such as low density, high strength and toughness, as well as ablation resistance at high temperature. These properties are suitable for applications such as thermal protection components in aircraft, rockets and the semiconductor industry. To make such composites, a state-of-the-art furnace for Chemical Vapour Deposition Infiltration . This vertical, multi- layer vacuum coating furnace is meant to deposit silicon carbide coating on the substrate using methyl-try-chloro-silane as reactant and hydrogen as a carrying agent under suitable temperature and pressure. With minimum modifications, this CVDCVI vacuum furnace can also be used to deposit a wide range of materials such as boron nitride, hafnium carbide, tantalum carbide , silicon nitride and silicon dioxide .

vacuum brazing furnaces

Get Price Quote

Reasons to Braze under Vacuum The following reasons support the use of brazing under vacuum: Calibrated use of alloy with magnesium (4045, 4044, 4104, 4004) to prevent excessive Mg sublimation in the vacuum chamber High final vacuum due to high capacity pumping systems (cryogenic pump + diffusion pumps), which produce a low oxygen atmosphere Rapid transition of the load temperature during the heating phase from 520 °C (starting temperature for Mg sublimation) to 605610 °C thanks to high power furnaces, a feature that prevents an oxidized layer (Al2O3) from reforming on the surface of the piece newly reduced to Al Suitable fixing systems of the individual heat exchanger prevent the piece from collapsing or deforming Uniform load temperature (± 3 °C at 605 °C) is achieved through accurate control of the output power and by distributing the heating zones Cleanliness of the components No emission of contaminated substances into the atmosphere Controlled cooling of the walls and other elements of the furnace with heated water (80 °C) to prevent atmospheric water vapor from condensing during loading and unloading process

Best Deals from Vacuum Furnace

Vacuum Furnace

Get Price Quote

Vacuum furnaces are preferred over conventional methods of heat treatment such as salt bath furnaces and controlled atmosphere furnaces due to the advantages it brings - such as prevention of surface oxidation, decarburization and low distortions on work pieces thus resulting in cleaner surfaces, less rework and less post-heat treatment cleaning or corrective operations.

Vacuum Furnace

Get Price Quote

We are offering Dry Vacuuming We remove the equipment from the oven and place it into a vacuum chamber, which removes air and any remaining moisture. Filling We fill the chamber with resin, coating the part and filling in all the gaps and pores in the piece of equipment. Wet Vacuuming We reduce the vacuum levels and hold it for a set period of time. Pressure We increase pressure within the chamber using dry air, nitrogen, or other gases. This allows for even deeper penetration of the resin. Draining We then vent the pressure, drain the chamber of excess resin, and remove the part. Vacuum Heat Treating Furnaces and Vacuum Technology Vacuum Furnace - Vacuum Annealing Furnace - Vacuum Heat Vacuum Furnaces and Sintering Furnaces and Lab Furnaces We are committed to Provide Vacuum Heat Treatment services to customers by Meeting their quality and delivery schedules, with emphasis on continual improvement of the Quality Management System Long-term relationship to achieve

Vacuum Furnace

Get Price Quote

1 Piece(s) (MOQ)

Vacuum Heat Treatment Furnace

200,000 Per Piece

Vacuum Furnace

Get Price Quote

INDVAC has designed and supplied various size of Vacuum Furnaces for special applications like, Vacuum Brazing, Annealing, Hardening, Tempering, etc. meeting to the customer requirements. INDVAC and Products are worldwide recognized for manufacturing and supplying superb quality Vacuum Furnaces. Our Industrial Vacuum Furnaces are made using the genuine raw material in order to meet international standards of high performance. These Pressure Vacuum Furnaces contain advanced features making them widely adaptable to cater to various requirements of customers.

Vacuum Furnace

Get Price Quote

Vacuum furnace has proven its mettle as a leading Vacuum Furnace manufacturer, manufacturing state-of-the-art Vacuum Furnaces for the automobile, electronics and aerospace industries at the most economical prices.

Vacuum Furnace

Get Price Quote

Vacuum Furnace

42,000 Per Set

Vacuum pumps , vacuum ovens,vacuum furnace ,vacuum metallizers ,vacuum pressure impregnation ,vacuum impregnation ,nitrogen chambers , vacuum pumps manufacturers in bangalore vacuum furnace manufacturers in bangalore vacuum metallizers manufacturers in bangalore vacuum pressure impregnation manufacturers in bangalore vacuum impregnation manufacturers in bangalore nitrogen chambers manufacturers in bangalore vacuum ovens manufacturers in bangalore vacuum pumps manufacturers,vacuum pumps,vacuum pumps manufacturers,vacuum rotetary pumps,pupms,pump,all types of pumps manufacturer,in bangalore karnataka,india,vacuum pumps manufacturers and supplers,vacuum furnace manufacturers in bangalore,vacuum oven manufacturers in bangalore,nitrogen chamber manufacturers in bangalore,vacuum metallizers,vacuum pressure impegration manufacturers in bangalore karnataka,india vacuumpumps-vacuumovens-vacuumfurnace-vacuum pressure impregnation-metallizers,nitrogen chambers manufacturers bangalore karnataka,india. Global vacuum products vacuum pumps,vacuum ovens,vacuum furnace,vacuum metallizers,nitrogen chamber,vacuum pressure impregnation systems vacuum pumps, vacuum ovens, vacuum furnace, vacuum pressure impregnation,vacuum metallizers,nitrogen chambers,vacuum impregnation manufacturers bangalore karnataka ,india

Vacuum Heat Treatment Furnace

Get Price Quote

Vacuum Theat treatment furnace manufacturers in India. Since its inception, Triad has been delivering high quality thermal processing equipment for customers. At Triad Engineers, we believe that innovative products and constant improvisation of the existing products. We do this by adding new features and pave a straight path for success and growth. Triad achieves this by partnering with other world leading heat treatment equipment providers.

Vacuum Furnace

Get Price Quote

The Mesh Belt Conveyor Furnace has been fabricated out of top notch quality raw materials that we have procured from our trusted vendors. They are furnished with brick refractory or molded ceramic fiber insulation, that is lighter, has less thermal mass, and lower thermal conductivity than conventional brick refractory. The Vacuum Heat Treatment Furnace Group provides advanced, energy-efficient and environmentally friendly vacuum heat treatment equipment with guaranteed process technology. Our vacuum furnaces are used in applications for annealing, brazing, sintering, gas quench (High Pressure Gas Quenching), vacuum oil quench, vacuum carburizing and nitriding (Low Pressure Carburizing, PreNit high speed vacuum carburizing), along with a wide variety of custom engineered process technologies.

Vacuum Furnace

29,000 Per Set

Http:www.globalvacuumproducts.com vacuum pumps, vacuum ovens, vacuum furnace, vacuum pressure impregnation,vacuum metallizers,nitrogen chambers,vacuum impregnation manufacturers bangalore karnataka ,india vacuum pumps manufacturers,vacuum pumps,vacuum pumps manufacturers,vacuum rotetary pumps,pupms,pump,all types of pumps manufacturer,in bangalore karnataka,india,vacuum pumps manufacturers and supplers,vacuum furnace manufacturers in bangalore,vacuum oven manufacturers in bangalore,nitrogen chamber manufacturers in bangalore,vacuum metallizers,vacuum pressure impegration manufacturers in bangalore karnataka,india global vacuum products-vacuum pumps,vacuum furnace,vacuum impregnation,vacuum ovens,vacuum pressure impregnation, vacuum metallizers, vacuum metalizer-vacuum metalizing machine,nitrogen chamber, vacuum impregnation,cuum pressure impregnation,vacuum metallizer,vacuum pumps.

Vacuum Furnace

6,000,000 Per Piece

vaccum furnace

4,000,000 Per Piece

Vacuum Heat Treatment Furnace

Get Price Quote

It is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the re-crystallization temperature and maintaining a suitable temperature, and then cooling. Annealing is used to induce ductility, soften material, relieve internal stresses, refine the structure by making it homogeneous, and improve cold working properties. Machining induces stresses in parts. The bigger and more complex the part, the more the stresses. These stresses can cause distortions in the part long term. If the parts are clamped in service, then cracking could occur. Also hole locations can change causing them to go out of tolerance. For these reasons, stress relieving is often necessary. Tempering is a process done subsequent to quench hardening. Quench-hardened parts are often too brittle. This brittleness is caused by a predominance of Martensite. This brittleness is removed by tempering. Tempering results in a desired combination of hardness, ductility, toughness, strength, and structural stability. Tempering is done immediately after quench hardening. When the steel cools to about 40 ºC (104 ºF) after quenching, it is ready to be tempered. The part is reheated to a temperature of 150 to 400 ºC (302 to 752 ºF).

Vacuum Heat Furnace

6,500,000 Per unit

High Vacuum Furnaces

Get Price Quote

As a leading global provider of high-quality vacuum products and systems, along with an established tradition of service and attention to detail, the Kurt J. Lesker Company® (KJLC®) has built a reputation for being “All Things Vacuum.” The common attribute across the entire company is the relentless and tireless pursuit of quality and customer satisfaction, both in the vacuum products and the services we provide worldwide. KJLC® takes this responsibility seriously, working at all levels to ensure high quality performance in all our products.

Laboratory Vacuum Furnace

Get Price Quote

vacuum furnaces

Get Price Quote

We are an eminent and leading trader of Vacuum Furnaces

Vacuum Furnace

Get Price Quote

Vacuum Furnace, diffusion pump, Silencer Cum Suction Filter Accessories

vacuum hardening furnace

Get Price Quote

vacuum hardening furnace, plasma nitriding furnace, Vacuum Annealing Furnace

Vacuum Brazing Furnace

Get Price Quote

Vacuum Brazing Furnace, vacuum hardening furnace, Vacuum Sintering Furnace

vacuum furnaces

Get Price Quote

Vacuum furnaces are preferred over conventional methods of heat treatment such as salt bath furnaces and controlled atmosphere furnaces due to the advantages it brings - such as prevention of surface oxidation, decarburization and low distortions on work pieces thus resulting in cleaner surfaces, less rework and less post-heat treatment cleaning or corrective operations.

vacuum furnaces

Get Price Quote

Vacuum furnaces are preferred over conventional methods of heat treatment such as salt bath furnaces and controlled atmosphere furnaces due to the advantages it brings - such as prevention of surface oxidation, decarburization and low distortions on work pieces thus resulting in cleaner surfaces, less rework and less post-heat treatment cleaning or corrective operations.

Vacuum Annealing Furnaces

Get Price Quote

Vacuum Annealing Furnaces, air circulating oven, Furnace Maintenance Services

High Vacuum Furnaces

Get Price Quote

High Vacuum Furnaces, PCD Fiber Laser Machine, Pdc Cutter, PDC Dies

Vacuum Furnace

Get Price Quote

Vacuum Furnace, Shaking Tables, KF Clamps, vacuum equipments

High Temperature High Vacuum Furnace

Get Price Quote

High Temperature High Vacuum Furnace, KF Clamps, diffusion pump

vacuum furnaces

Get Price Quote

vacuum furnaces, Diffusion Vacuum Pump, epoxy mixing plants