Small & portable vibrating screen

89,500 Per Piece

1 Piece(s) (MOQ)

portable oscillating screen is designed for small capacity screening applications with single vibration motorized system. this screen consists of a removable tray with mesh mounting arrangement and also features a leveling gate.the lower tray used for the flow of the screened product. this screen is available with side discharge outlet with different size tray to suit different production lines. vibeng's design features : 1.removable tray with mesh mounting arrangement. 2. leveling gate for control feed rate. single vibration motor driven system. 3. available with good branded electrical vibrator and oscillating mounts. 4. less maintenance and minimum downtime. 5. m.o.c-material contact part in ss304 with matt finish and base frame in ms. benefits : 1.applicable for low capacity line. 2. high screening efficiency with low cost. 3. low noise.

Vibrating Screen

Get Price Quote

Best Deals from Vibrating Screen

High-frequency Screen

Get Price Quote

Compared with the commonly screening and grading equipments, the High-frequency screen adopts higher frequency. As a result, it is able to damage tension force of the pulp surface. Also the fine particles are able to oscillate speedily on the surface of the screen because of the high frequency, and the big expecting minerals are isolated from the pulp easily. Features High-frequency screen adopts the most advanced theory and new structure. High vibrating frequency leads to high screen efficiency and big capacity. Controlled by computer, every exciter specification is adjustable. Also it sets up a transient extremely vibrating force, which is quite useful in clean the screen surface. Low powder consumption: High-frequency screen adopt super Elastic material, which ensure the steadiness and help to save the power. Application High-frequency screen is a good choice for screening and grading the fine particles of mineral ores. This machine has wide application in iron ore, tin ore, tungsten ore, tantalum ore, dolomite sand and some other kinds of mining dressing plants' screening and grading work.

YKN Vibrating Screen

Get Price Quote

Depend on decades-years� experience in mining industry and latest technology, GME designed the YKN series vibrating screen, which has high-strength exciting force.YKN series vibrating screen adopts the eccentric vibration exciter of N series. And the transmission adopts flexible connector. As a result, the amplitude is bigger and the vibration is much more stable than old types. Also the throughput and screening efficiency are greatly improved. Features: The exciter adopt outer eccentric block, the weight is light and the exciting force is strong. Operators can easily adjust the amplitude and exciting force by changing the eccentric blocks quantity. The vibration exciter is fixed on the side-bar of screen box and two exciters are connected by universal coupling, so it is very easy to install and maintain. For the transmission adopts flexible connector, there is no force transmit along the main shaft and it ensures the stable performance. Applications: YKN Vibrating Screen is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on. For material quality of screen mesh is changeable, the application is quite extensive.

Vibrating Screens

Get Price Quote

Vibrating screens are widely used for grading and screening materials in such fields as chemical industry, minerals, quarry, building materials, water conservancy and hydro power, transportation, smelting and so on. Vibrating screens are efficient screening machines for the classification of bulk material such as coal, minerals, sand, coke etc., There are 40 specifications for this series vibrating screen, of which the heavy duty type of vibrating screens are for the classification of large size materials, while the light duty type of vibrating screens are for the middle and small size materials. Applications: Grading & screening in Mineral Processing Quarry Chemical Industry Building materials Water conservancy Transportation Smelting & so on FEATURES & BENEFITS This series of vibrating screens use eccentric block to produce strong Exciting force. Crossbeam and the main body of the vibrating screen are connected with high strength screw bolts. So our vibrating screens have the features of simple structure and easy maintenance. The vibrating screen adopts tyre coupling with capability of flexible connection and stable operation. Creative’s - vibrating screens adopt the structure of small amplitude, high frequency, large obliquity to make the screen hold the capability of high efficiency, large handling capacity, long life span, low consumption, and little noise; you will find this series of vibrating screen optimized for your demands.

Vibrating Screen

Get Price Quote

The Vibrating Screen, which we offer, performs flawless performance in separating coarse materials from the fine materials. Additionally, the metals used in the manufacturing of the Industrial Vibrating Screens are of optimum quality, which ensure their high durability and resistivity to corrosion. We provide the Vibrating Screens in varied sizes and dimensions as per the needs of the clients. Why Our Vibrating Screen? High screening capacityEasy to maintainDurableSmooth finish

Vibratory Screen Separator Machine

200,000 - 300,000 Per Piece

5 Piece (MOQ)

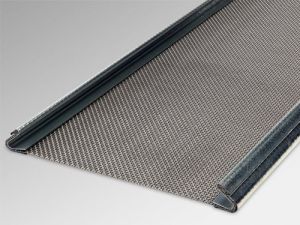

Vibrating Wire Mesh Screen

499 Per Piece

8 Piece (MOQ)

Vibrating Screen

Get Price Quote

Our range of Vibrating Screen are extensively used in grading and screening material in the fields of minerals, building and so on. We have fabricated these Vibrating Screen using quality raw material procured from trusted vendors. We comply to all quality standards laid by the industry. Apart from being high on performance, reliable and anti corrosive, these Vibrating Screen exhibit high performance with reliable service. We offer these Vibrating Screen at reasonable prices. Benefits of using Vibrating Screen Widely used for grading and screening materials in the fields of minerals, quarry, building materials water conservancy and hydro power, transportation, chemical industry, smelting and so on. Vibration mechanism creates natural screening effect. Different size hole screening sheets screens the output material of the desired dimensions Suitable for course as well as fine grain material Salient features of using Vibrating Screen Heavy duty bearing shaft mechanism for long durability Optimal screening area that provides high screening performance Easy of use for necessary adjustment Extra-heavy construction Heavy coil spring support system Variable sized models provides high adaptability with custom requirement Multiple deck adjustment for variable output requirement High strength bolting system to withstand vibration Heavy duty frame structure for long durability against vibration resistance

Vibrating Screens

4,500 Per Piece

Vibratory Screen

Get Price Quote

We are offering vibratory screen.aircon provide vibratory screen, which is available in varied specifications to suit the requirements of different industry applications. These screens are mainly used to screen and grade different material into small particle sizes. We offer customization on our range as per the demands of our clients. features: * rugged construction * low maintenance * durable * precision functioning

Mobile Vibrating Screen

Get Price Quote

Built either as a double or triple-deck screen with or without feed hopper, as a banana screen, with finger screening surface, with rubberised perforated panels, etc. the screens are suitable for use wherever high outputs are required and where difficult to screen material has to be separated.The screens are all diesel-electric driven and are particularly suitable for combined operation with an upstream Liming crusher. The performance range for mobile screens nowadays extends to 1,000 t/h depending on the type and composition of the feed material and the grading ranges to be screened. Processed Materials : Concrete waste, iron ore, copper ore, gold ore, manganese ore, gravel, granite, river stone, basalt, limestone, dolomite, quartz, coal, etc. Applications : Mining, metallurgy, construction, highway, railway, and water conservative, etc. Features Built either as a double or triple-deck screen with or without feed hopper, as a banana screen, with finger screening surface, with rubberised perforated panels, etc. the screens are suitable for use wherever high outputs are required and where difficult to screen material has to be separated.The screens are all diesel-electric driven and are particularly suitable for combined operation with an upstream Liming crusher. The performance range for mobile screens nowadays extends to 1,000 t/h depending on the type and composition of the feed material and the grading ranges to be screened.

Inclined Screen

Get Price Quote

This model simulates the flow through a uniform inclined screen using the Screen feature in Single-Phase Flow physics and compares the results with an analytic solution.

Vibrating Wire Screen

Get Price Quote

Vibrating screens are manufactured with clamps on either sides which are made by Spring Steel, High Carbon Steel, Stainless Steel, Galvanized Iron & Mild Steel Wire as per client's required sizes and are manufactured with providing High tensile abrasion resistant being mainly used in mines & quarry industries, coal mines, foundries, heat treatment & waste management etc. These Heavy / Vibrating Screens are also generally used for screening of various products & sizing or processing heavy abrasive materials like ores, crushed stones etc.

Vibrating Wire Mesh Screen

130 Per Square Feet

50 Square Feet (MOQ)

Vibratory Screen

Get Price Quote

Vibratory screens and heavy crimped wire meshes are mostly used for sieving heavy ores. Mainly used in fencing and concrete reinforcement and crushers in cement plants. We offer customer made vibratory screens made of different aperture sizes and metals with an option of folded edges. Our range of vibratory screens includes dewatering screens, screen separators, linear motion screens and vibratory screen separators.

Vibrating Screens

Get Price Quote

Ingwenya Mineral Tech offers high performance and reliable Vibrating Screens for the mineral recovery sector. Special arrangements with industry leaders like Screen Doctor, South Africa enables us to source and supply the latest in Vibrating Screens to suit varied applications. Designed and engineered with high levels of customization to meet your specific needs and applications, Ingwenya Mineral Tech offers a full range of light and heavy duty Vibrating Screens to handle various materials. Vibrating Screens from Ingwenya Mineral Tech are available in various options: Suspensions: Springs, Rubber & Screen Mounts Screening Surfaces: Woven Wire, Wedge Wire; Poly Panels & Rubber Panels Deck Frames: Runner or Box type Exciters: 2 or 4 vibrator motors & geared exciters Liners: Hard wearing plate, Polyurethane, HDPE & Rubber lined plate Fabrication: GR300WA, 3CR12, 304 and 316 Stainless steel Protection Coatings: Enamel Painting, Powder Coating or Hot Dip GalvanizingVibrating Screens from Ingwenya Mineral Tech are suitable for a wide range of applications like: Mining: Coal, Gold, Platinum, Diamonds, Iron Ore, Chrome & other base metals Industrial: Foundries, Glass, Recycling & Chemical Food Industry

Vibratory Screen

Get Price Quote

Aircon provide vibratory screen, which is available in varied specifications to suit the requirements of different industry applications. These screens are mainly used to screen and grade different material into small particle sizes. We offer customization on our range as per the demands of our clients. features: •rugged construction •low maintenance •durable •precision functioning.

linear screen

Get Price Quote

Linear screen widely used for thrash removal before feeding to the main process. VMix is having customised design to treat various capacity. Our equipment capable of screening too slime material. 2000 microns Low water and power consumption. Low construction material. Less footage space requirement. Low maintenance and simple structure. Application- Wet Processing, Slurry preparation.