Twin Tube Washing and Drying Machine

Product Description: Minimum order value is Rs. 10 lakhs and above , This machine is used to wash Twin tube used in shox absorbers after the welding operation . The hot water is used to wash and air is used to dry the components.

...more

Twin Station Gas Filling Machine

Product Description: Minimum order value Rs. 20 lakhs and above ,This machine is used to fill the gas in the shox absorbers after the oil filling by lip opening and filling the gas and also crimping the component once it is filled.

...more

Shox Testing Machine

Minimum order value Rs. 3 lakhs and above , This machine is used to check the shox’s absorbers life , by simulating the condition of the shox’s mounting in the vehicles.

...more

Shox Outer Tube Washing Machine

Product Description: Minimum order value Rs. 10 lakhs and above ,This machine is used to wash outer tube used in shox absorbers after the welding operation . The hot water is used to wash and air is used to dry the components.

...more

Shox Final Assembly Machine

Description: this machine price minimum Rs. 4 lakhs and above , This machine is used to assembly the shox absorbers parts , like spring , nut and eyelet in the piston rod by compressing the spring and by using the nut runners.

...more

Leak Testing Machine

Product Description: This machine is used to detect any welding or air crack leakage in the shox’s or Front Fork outer tube , by high pressure air filling and by immersing in the water.

...more

Industrial Vulcanization Tunnel Ovens

Our product range includes manufacturing and supply of Vulcanization Tunnels. The high-skilled research department of ELMETHERM has developed a wide variety of continuous process ovens. Since each product requires a specific process, we offer a large range of solutions for conveying, controls and air flow design. Specifications: Vulcanization of rubber hoses High velocity vertical ventilation Heating tunnel and cooling tunnel

...more

Industrial Twin Station Welding Machine

The minimum price for the machine will be Rs. 8 lakhs and above ,This machine is used to weld shox outer tube to i ring at two points torch up & down is controlled by pneumatic cylinder. Component rotation is controlled by servo motor with heigh precision planetary gear box.

...more

Industrial Trim Carousel System

We manufacture and supply Trim Carousel Systems. We work close to our customers to design the best automated material handling system to answer to their specific needs and improve all their thermal process applications. Specifications: 4-stations trim carousel system Preheating / pressing / heating / cooling Very compact solution.

...more

Industrial Torquing Machine

Minimum order Value Rs. 10 lakhs and above ,This m/c is used to do bolt cap torquing in front fork. for torquing hydraulic orbital motor is used . torquing gun assy. slids on lm guideways up & down . component clamps by parallel griper operated by hydraulic cylinder. in this m/c while torquing first spring with bolt cap in to the inner tube of front fork then torquing operation done.

...more

Industrial Spinning Machine

Minimum order value Rs. 10 laks and above , This machine is used to do spining offront fork inner tube & outer tube of shock absorber spinning operation is done by spinning head with help of electric motor. This spinning head connected to spindle housing , which is fixed at top of column. component is moved against spindle from bottom by hydraulic cylinder to don spinning operation.

...more

Industrial Spin Riveting Machine

Minimum order value Rs. 3.5 Lakhs and above , This machine is used to do spin riveting of piston rod to lock the piston. This m/c contains two stations parallel gripper is used to grip the component gripper is operated by pneumatic power for riveting operation `orbital’ make spin riveting head is used.

...more

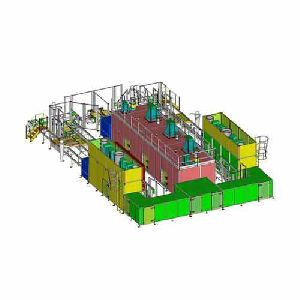

Industrial Polymerization Tunnel Ovens

We are leading manufacturer and supplier of Polymerization Tunnels. Our product range comprises of various types of polymerization tunnels. Specifications: Hot-water heated batch oven 2 heating zones & one cooling zone. Parts on carts

...more

Industrial Oil Filling Machine

Minimum order value Rs. 5 lakhs and above , This m/c is used to fill the oil into the inner tube of front fork & shock absorber. despending of oil quantity controlled by adjusting stopper block .this stopper height adjusted with the help of servo motor. oil dispencer is operated by pneumatic cylinder. oil filters are used in oil line to filter oil.

...more

Industrial Heat Treating Vertical Oven

We are the known manufacturer and supplier of Heat Treating Vertical Ovens. The heating Source used includes: Heating by gas burner or electric Possibility to have several temperature controlled zones in the same tower. As well as a cooling zone prior to the unloading integrated in the tower.

...more

Industrial Gas Filling Machine

Minimum order value Rs. 10 Lakhs and above , This special purpose machine is used to fill the oil and gas in shock absorber. This machine is specifically designed for 6-different shock absorber models. they are yc5, yy4, zen rr, 800 cc rr, wagonr – rr, alto rr. ‘Oil and gas filling machine ‘is used for following purposes. - At riveting position, the component gets plugged partially to press fit. - At sealing position, Oil and gas filing is done. This machine works by pneumatic and hydraulic systems. The oil and gas filling component is placed on component locator, where it is incorporated with load cell and pneumatic cylinder on central slide assembly.

...more

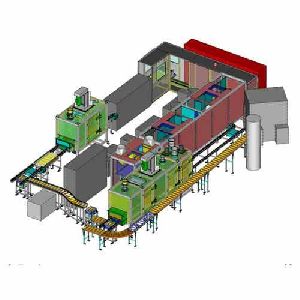

Industrial Front Fork Assembly Line

The minimum order value is Rs. 15 lakhs and above , This line is used to assembled front fork of shock absorber . in this line chain conveyor is used to transport component from one station to another station. dust seal & circlip pressing; oil filling & assembly of component to be done on conveyor.

...more

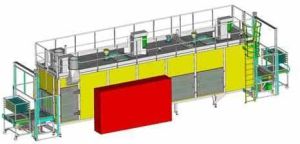

Industrial Fluxing Ovens System

Because the product is unique, the best way to heat it properly is to have good temperature uniformity. Thus, depending on the process we can assure temperature up to -5C up at 300C (570F).The speed and direction of airflow have the most impact on the temperature uniformity, thus they will be determinate specifically to your product specifications. ELMETHERM offers the most suitable air flow styles (top to bottom, bottom to top, Transversal, Longitudinal, counter flow, multi flow). The appropriately located pressure plenums will lead the air to the product through nozzles or adjustable whole area of heating and ensuring good temperature uniformity throughout the cycle. Specifications: Fluxing system for aluminum heat exchanger High pressure vertical ventilation

...more

Industrial Custom Batch Oven

Elmetherm manufactures a wide variety of custom batch ovens or composite batch ovens from 1m3 (35ft3) to 200m3 (7,000ft3) to accommodate your special requirement of temperature, uniformity adapted to your process and product. Specification: Composite polymerization Temperature regulation on the parts Temperature uniformity 250°C +/- 5°C (480°F +/- 9°F)

...more

Industrial Curing Vertical Tower Ovens

Minimum order valve Rs. 1000000 /- and above Our product range comprises of Curing Vertical Towers. This type of tower is extremely compact. By stacking trays, it is possible to work at high temperatures without sticking risks thanks to a simplified mechanical system without using chains. Specifications: Curing tower 570 Automated loading/unloading by a robot Fume/VOC incinerator and energy recovery exchanger

...more

Industrial Composite Wire Polymerization Tunnel Ovens

Our products are used for: Impregnation and drying of composite wire. 2 heating zones & one cooling zone.

...more

Industrial Composite Curing Vertical Oven

Minimum order value is Rs. 15 Lakhs and above , Considering the customers' expectations ELMETHERM could custom any vertical ovens in the best way to improve your process without adding labor or losing floor space. Loading and unloading could be placed at the same or different positions and operated by robot, manipulator, conveyors or manual. Specifications: Composite curing vertical oven Indexing conveying system Manual loading/unloading at the same station

...more

Industrial Coating Ovens System

We offers manual and automatic powder coating equipments including electrostatic powder coating gun, powder optimization equipment, powder recovery system. Ovens for Rubber Curing / Coating Applications have coating line for sensors: Pre-heating tunnel Gelification tunnel Polymerization tunnel

...more

Industrial Clean Room Batch Oven

For each Product, the best air flow type is chosen based on the product configuration. With possibilities of top-down, bottom-up, top-bottom, longitudinal or multi-flow we assure the oven to have a temperature uniformity flow we assure the oven to have a temperature uniformity of /-5C up to 300C (570F). Our quality team tests every oven before shipment and provides temperature charts. provides temperature charts. Specifications: Drying batch oven Clean room standard construction

...moreBe first to Rate

Rate ThisOpening Hours