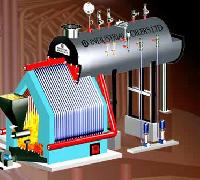

Combloc Solid Fuel Fired Steam Boiler

1,500,000 - 5,000,000 Per Piece

1 Piece (MOQ)

Solid Fuel Fired Steam Boiler

500,000 - 1,000,000 Per Piece

Best Deals from Solid Fuel Boiler

Multi Fuel External Furnace for Boilers

Get Price Quote

1 Piece (MOQ)

We specialize in the field of up-gradation of existing boilers for pollution free performance. Our main area of operation is to up-grade existing boilers to pollution free and smokeless multi-fuel furnaces to save steam generation cost. With increasing competition amongst industries and continuous increase in the costs and uncertain supplies of the various fuels all industries are forced to change over to alternate or multi-fuel firing and switch over to low cost fuels, depending upon the location or nature of operation. Keeping these in view, our main areas of operation are: Designing, supply and installation of multi fuel including biogas firing furnaces for existing boiler. Trouble shooting related to boilers and other equipment / accessories. Annual maintenance and operation of these systems / units.

Solid Fuel Fired 1000-15000 Kg/hr COMBIPAC Steam Boiler

1,500,000 Per Piece

1 Piece (MOQ)

-1718278525-7479168.jpeg)

Package boiler ( solid fuel )

600,000 - 1,200,000 Per Bag

Highly efficient package boiler, suitable for all kinds of fuel

Solid Fuel Fired Steam Boiler

Get Price Quote

Manufacturing under Internationally accepted Inspection Agencies i.e. IBR, Lloyd's, SGS, Bureau Veritas, TUV or any others as per client's requirement.

Solid Fuel - Fired Steam Boilers

Get Price Quote

SPECIFIC ADVANTAGES: Presently exempted from Indian Boiler Regulations No qualified or full time boiler attendant is required. Full pressure steam within three minutes from cold start. Compact. Minimum space and weight Explosion-proof Fully automatic after a manual start. High efficiency-low operating cost. High velocity Burner: Pressure atomized type for positive clean performance. Capable of meeting fluctuating loads. Steam is produced as it is used.

Solid Fuel Fired Steam Boilers

Get Price Quote

We manufacture ibr approved solid fuel fired steam boilers . Its a 3 pass, fully wet back horizontal multi tubular design with centre furnace. Our boilers are of high efficiency and eco friendly

Solid Fuel Boilers

Get Price Quote

Not just designing and manufacturing, but we make sure that the packaging of the products is also given the priority. Our packaging experts make use of quality packaging material to deliver the product undamaged. We can carry out excellent supply chain management, as we have an ultramodern warehouse and the latest inventory control systems. Both help us meet bulk requirements and save us from stock out situations. Types of boiler we supply are as follows : Smoke tube boiler Water tube boiler Capacity - 500 kg/hr up to 10 TPH Steps involved in supply of Boiler : Calculation of load requirement. (Steam demand in process) Sizing of boilers & accessories Supply, Erection & Commissioning of boilers Guidance for government authorities & approvals. (IBR, Pollution Control Board & Safety Inspector) Supply of manpower viz. Boiler Proficiency Engineers, Boiler operators, firemen, helpers for operation & maintenance of boilers on chargeable basis Fuel supply on chargeable basis Internal grate Fired Boiler: Photo of Pepsi co boiler We supply (i.e. Design, Erection & Commissioning) internal grate boiler where firing of fuel (briquette) is done manually on internal grate fitted inside a boiler, bars are locked by internal locking system Boiler mostly used are shell & tube type, so gas pass through tubes & water is filled up to a predetermined level in shell, the level of water is indicated by Mobre unit, one of the boiler mountings Heat conduction converts water into dry saturated steam which ultimately utilized at the site of application Cyclone or Scrubber is provided for purification of flue gas & ID fan for combustion All boiler accessories, mountings & fittings are assemble according to IBR/Semi IBR norms as and when required Flue gas which passes through chimney to atmosphere is free from all hazardous effluents; it is according to requirement of Pollution Control board Advantages of Internal Grate Boiler : Compact in size Less heat transfer loss Higher temperature difference External furnace Fired Boiler : We supply (i.e. Design, Erection & Commissioning) external furnace fired boiler where firing of fuel (briquette) is done manually by fireman inside an external furnace Trolley duct connection transfers heat from furnace to tubes of boiler Boiler mostly used are shell & tube type, where gas pass through tubes & water is filled up to pre-determined level in a shell Process of steam generation is same as an internal grate boiler Cyclone or Scrubber is provided for purification of flue gas & ID fan for combustion We also provide arrangement of Water Pre heater (WPH) which supplies make up water to boiler so that production time of steam get reduced All boiler accessories, mountings & fittings are assembled according to IBR/Semi IBR norms Flue gas which passes through chimney to atmosphere is free from all hazardous effluents; it is according to requirement of Pollution control board Advantages of External Fired Boiler: High thermal mass Old (Existing) boiler can easily be converted No IBR modification required as pressure parts are kept untouched Provides complete combustion

solid fuel steam boiler

800,000 Per Set

Solid fuel steam boiler Available capacity - 1.0 Ton to 14 Tons

FUEL CROSS BOILER

7,800 - 8,500 Per piece

5 Piece (MOQ)

Solid fired Steam boilers

Get Price Quote

Design and manufactured as per IBR. Combine design of smoke tube & water tube results in excellent performance. Furnace design offer higher solid fuel flexibility, furnace can be operated on fluidizes bed combustion. Furnace design offers high solid fuel flexibility. Flexibility to use different fuel with FBC furnace. Higher efficiency can be achieved with FBC furnace. High steam chest volume. Good response for the fluctuating load of steam. Enough grate area to ensure complete combustion. Heat recovery unit like air preheater, water preheater option are available for high efficiency of boiler. Multi dust collector / bag filter option is also available to meet the requirement of pollution control board.

solid fuel steam boilers

Get Price Quote

1 Piece (MOQ)

We are offering solid fuel steam boilers. Integral furnace - solid fuel boilers are the most suitable design for customers with space constraints and still wants to take advantage of using agro-waste (agro waste) fuel. The installation cost is low and does not require refractory maintenance as usual in solid fuel boilers. This boiler has little lower efficiency, but the other advantages are much beneficial for a smaller installations. We recommend to use these boiler design upto 6 tph. Advantages: high water hold-up, less installation space, less installation cost, no refractory, good response to fluctuations in steam pressure.

Steam Engine Dry Fuel Heated

3,500 Per Piece

Steam engine dry fuel heated : the model is a ready to run single-acting, oscillating cylinder, dry fueled engine with a 2-18 x 4-14 nickle plated brass boiler. The is excellent for student science fair projects or for simply enjoying your own little steam engine. This easily operated engine is an excellent choice for the beginning steamer.

Solid Fuel Fired Steam Boiler

2,990,000 Per Piece

Solid Fuel Boiler

Get Price Quote

The Intell series of boilers is a truly packaged and compact range, available in capacities of 0.6 TPH to 4.5 TPH. The necessary automation for fuel feeding, air to fuel ratio, cut off cut in of boilers are inherent in design along with safety features.

solid fuel steam boiler

Get Price Quote

We offer heavy duty Solid Fuel Steam Boiler in the market. It is a Smoke tube type system boiler with three pass fully wet back design, suitable for coal, wood, briquette, lignite, and growaste. Salient Features Factory-assembled horizontal package boiler. Less site work & quick commissioning Suitable for coal, wood & briquetted fuel. Manual firing less complexity. Large integral furnace minimum heat loss. High turn-down ration. End to end visibility of tubes. Easy access for inspection & cleaning. Quick and easy ash removal. Low excess air burners, imported / indigenous.

Solid Fuel Fired Boiler

Get Price Quote

Rakhoh Enterprises is a leading name in the domain of Solid Fuel Fired Boiler. We have our team of technical experts that designs Solid Fuel Fired Boiler which can cater to the needs of our customers. Fuel used : WoodCoalBagasseBriquettesSaw DustRice HuskCoffee HuskAgriculture WasteOilGas

Solid Fuel Fired Steam Boilers

500,000 - 12,000,000 Per Piece

1 no (MOQ)

The Solid Fuel Fired Steam Boilers offered by us are available in vertical and horizontal smoke boiler. These solid fuel fired steam boilers use wood and coals as fuel. The boilers have adequate heating surface ensuring uniform performance. Advantages of Solid Fuel Fired Steam Boilers :- Economical in operating cost Bigger diameter of smoke tube ensures smooth passage of fuel gases and prevents choking Easy to clean and maintain Adequate heating surface for uniformheating Specifications of Solid Fuel Fired Steam Boilers :- Available in 100 kg/hr to 8000 kg/hr Working Pressure: 22 Bar Profile :- AQUATHERM - SF is a Solid Fuel Fired Hot Water Generator.It is available in Vertical & Horizontal Smoke Tube Type Range-10,000 kcal/Hr. to 400,000kcal/Hr.Temperature Range 90°C at atmospheric pressure.140 & 180°C Pressurized type. Design Features :- • Most Economical in operating cost No water treatment required when used with Calorifier.

Solid Fuel Boiler

Get Price Quote

1 Kgs (MOQ)

Solid Fuel Fired Steam Boiler

Get Price Quote

rsw - solid fuel fired shell type flue tube steam boilers the rsw series is a horizontal shell type integral furnace, flue tube, solid fuel fired steam boiler. Capacities available are from 500 kgs/hr upto 3 tonnes/hr steam in double furnace design. Units are designed as per indian boiler regulations. It can be used on various fuels such as coal, lignite, wood, & bagasse pellets. An induced draft fan is provided for proper combustion & balanced draft in the combustion chamber. High thermal efficiency is achieved by using a large furnace, a very efficient burning system & correct heat release rate between radiant and convective sections. Boilers are designed to ensure uniform distribution of thermal and mechanical stresses in heat transfer surfaces. the advantages of the rsw series units are minimum space required due to compact design fast startup, erection & commissioning. very easy to operate & maintain. low power consumption hinged doors for easy inspection & maintenance of boiler.

SMALL INDUSTRIAL DESIGN SOLID FUEL FIRED BOILER

Get Price Quote

ibr approved small capacity boilers 100 kgs/hr to 800 kgs/hr multifuel - coal/wood/briquette fired pressure 100 psig -7 kg/cm2 ideal for small & medium industries both vertical & horizontal designs available high efficiency lower investment compared to ibr boilers easy maintenance quick after sales service over 1000 installations.

Solid Fuel IBR Steam Boilers

Get Price Quote

Packaged Type fully wet back solid fuel IBR Steam Boilers Type : Three pass, horizontal, smoketube, fully wetback, packaged boiler, conforming to the latest revisions of Indian Boiler Regulations (IBR). Capacity : 600 to 10000 kg/h ( F & A 100° C ) Working Pressure : 10.54 / 14.5/ 17.5 kg/cm2 (g) and above. Fuel : Coal, lignite, petcoke , firewood, bagasse, husk / other agro waste etc.

Solid Fuel Central Heating Boiler with Stoker

Get Price Quote

All kinds of solid fuel can be burnt easily Fuel feeding is under the combustion chamber, so boiler efficiency is higher & waste materials are less than others. The bunker, once filled by user, need not filled again for approximately 3 days due to its large capacity. Due to large feed cover, combustion chamber is easily accessible and ignition operation is simplified. Combustion chamber is covered by refractory concrete material which increases the temperature around this area. Temperature adjustment , fuel feeding & waiting time can be adjusted by means of Control Panel. When the boiler temperature exceeds 90 ºC, Limit thermostat shuts down the reducer & fan but circulation pump continues to work. Further, when the water temperature falls down below +4 ºC, circulation pump works automatically for blocking the freezing risk. As a result of all these, the Boiler operation is highly efficient & economical Applications : For economical heating and comfort Capacity Range : 90,000 – 3,00,000 kcal/hr . Available in six models Capacity Range : 3,50,000 – 10,00,000 kcal/hr . Available in seven models

Solid Fuel Boilers

Get Price Quote

we are one of the thriving fuel fired boilers manufacturers and suppliers based in india. we are the only one who ensured safety as well because steam at such high pressure or temperature can cause serious incident, so we assured you to provide impeccable solid fuel boilers. we offer you exclusively high in technology solid fuel fired boilers with unmatched features i.e. three pass high efficiency boiler, choice of fuel feeding system, microprocessor controlled fuel feeder, large water cooled safe furnace, and packaged concept, ultra long life flu dishing nozzle etc. even this solid fuel fired boilers are totally sound free. so place your order now.

Solid Fuel Fired Steam Boilers

Get Price Quote

Solid Fuel Fired (SIB) Steam Boilers Capacity: 300 kgs/hr pressure 7 kgs/sqcm. Type: horizontal, shell type smoke tube boiler. Fully automatic, three pass wet back design. High efficiency 75±2 [NCV]. Fitted with all safety and indigenies accessories. Can be designed to meet customer specific requiremts.

Solid Fuel Fired Steam Boiler

Get Price Quote

The Solid Fuel Fired Steam Boilers offered by us are available in vertical and horizontal smoke boiler. TheseSolid Fuel Fired Steam Boilers use wood and coals as fuel. The boilers have adequate heating surface ensuring uniform performance. Advantages of Solid Fuel Fired Steam Boilers :- Economical in operating cost Bigger diameter of smoke tube ensures smooth passage of fuel gases and prevents choking Easy to clean and maintain Adequate heating surface for uniformheating Specifications of Solid Fuel Fired Steam Boilers :- Available in 100 kg/hr to 8000 kg/hr Working Pressure: 22 Bar Profile :- AQUATHERM - SF is a Solid Fuel Fired Hot Water Generator.It is available in Vertical & Horizontal Smoke Tube Type Range-10,000 kcal/Hr. to 400,000kcal/Hr.Temperature Range 90°C at atmospheric pressure.140 & 180°C Pressurized type. Design Features :- • Most Economical in operating cost No water treatment required when used with Calorifier.

Boiler Smoke Water Tube Solid Fuel

Get Price Quote

Smoke and water tube combination , external furnace solid fuel fired boiler with flexibility in fuel use. Capacities 2 TPH to 10 TPH.

Solid Fuel Thermal Boilers

Get Price Quote

The most renowned name in heating systems now brings to you a wide range of Thermic Fluid Heaters for superior applications with almost any type of fuel like Oil, Coal, Wood, Saw dust, Lignite, Bagasse, Husk, GN shell etc. Today there are over 1000 installations of Shanti Heating Systems throughout the country practically in all type of industries like Drugs & Pharmaceuticals, Chemicals, Textiles, Food processing, Dairy plant, Tannery, Plywood, Solvent extraction etc.

Packaged Solid Fuel Boiler

Get Price Quote

VOLFRAM offers high efficient 3 pass internal furnace packaged solid fuel fired steam boilers. Capable of being fired on Wood/Solid agro waste, Coal this is capable of achieving high thermal and combustion efficiencies through the optimum sizing of steam output. Utilizing the 3 pass wet back concept the full combustion of fuel takes place within the large furnace before passing into the fully submerged wet back reversal chamber. Two passes of convection tubes then carry the hot flue gases through the two convection tube bank in the boiler and thus ensuring complete transfer of heat for steam generation and thus ensuring high efficiency. Features of Packaged Solid Fuel Boiler: Saddle Mounted Boiler The entire unit is saddle mounted, including all accessories - only connections for water, I D fan, chimney, electricity and steam outlet are required to commission the boiler. Mountings & Accessories VOLFRAM Boilers are fitted with mounting and accessories of international repute and standards, the feed water pumps are the vertical multistage SS pumps. Truly packaged type The Boiler Comes Pre-wired & pre-insulated from the factory itself reducing the site work & cost of site activities. Centrally Located Furnace This ensures no tubes in cold zone & enhances effective heat transfer resulting into lower start up time. Better Response to Fluctuating Loads The higher steam space inside the boiler results in better response to Fluctuating steam loads. TDS based Automatic Boiler Blow down The boiler is provided with TDS based automatic boiler blow down system which ensures optimum blow down from the boiler. Capacity Range: From 1000 kg/hr to 5000 kg/hr. Standard Design Pressure: 10.54 kg/cm2 (g), 17.5 kg/cm2 (g) & 21 kg/cm2 (g) VOLFRAM offers complete package for the Boiler House consisting of Self Operated PRV has high turn down ratio due to which it responses well to the fluctuating loads. Chimney Pollution control equipments Piping (IBR/NIBR) Feed water tank with accessories On site IBR formalities