Trench Digger Machine

A trench digger can be used for trenching, or it may be done by hand with a shovel or pickaxe. Larger trenches are difficult to dig by hand, so a motorized machine has been specially designed to do the job. Trench diggers come in a wide range of sizes to accommodate the digging of many different sizes of trench. Smaller trench diggers are small enough to be operated by one person pushing the digger along the area to be trenched. Larger trench diggers, common in construction settings, are massive machines that must be driven. A large, saw-like arm is lowered to the ground to dig the trench.

...more

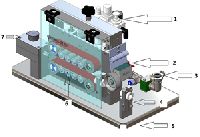

cable blowing machine

Optical Fibre cable blowing machine can blow OFC in PLB ducts 40 mm Dia to 50 mm dia at an velocity of 70 meters per minute and machine can accommodate cable size 14 mm dia to 25 mm dia of any configuration either armored or unarmored, machine is run by air drive system powered Ingersoll Rand and machine weighs only 38 kgs. It is very easy to lift from one work point to other point easily, operations of machine is very simple requires only two lever control and can be handled by semi-skilled person. We have sold so many machines in India, Middle East countries, African and Srilanka. Duct Collate size: multi collate sizes for 32mm, 40mm and 50mm in combined pack. The machine also comes with only 40 mm duct collate and 50 mm duct collate..

...more

Automatic Splicer

splicing is the act of joining two optical Fibres end-to-end using heat. The goal is to fuse the two Fibres together in such a way that light passing through the Fibres is not scattered or reflected back by the splice, and so that the splice and the region surrounding it are almost as strong as the virgin Fibre itself. The source of heat is usually an electric arc, but can also be a laser, or a gas flame, or a tungsten filament through which current is passed. Current fusion splicers are either core or cladding alignment. Using one of these methods the two cleaved Fibres are automatically aligned by the fusion splicer [1] in the x, y, z plane, then are fused together. Prior to removing the spliced Fibre from the fusion splicer, a proof-test preformed to ensure that the splice is strong enough to survive handling, packaging and extended use. The bare Fibre area is protected either by recoating or with a splice protector. A splice protector is a heat shrinkable tube with a strength membrane. Optical splicing procedure.

...more

network design

trenching

Patch Cords

optical fibre

Joint Closure

Splicing Machine

Optical Time Domain Reflectometer

Horizontal Directional Drilling Machine

power meters

Be first to Rate

Rate ThisOpening Hours