vertical turning machine

Vertical Lathe

Our company has achieved widespread recognition in offering VL Turret Type Vertical Lathe to the clients. This product is available in various technical specifications and models in market and is provided by the deft professionals.

...more

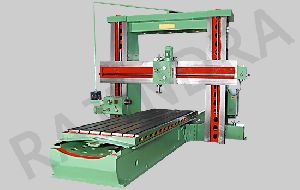

Plano Miller

Planer Machine

Milling Head

lathe machine chucks

We are dealing in replacement spares and accessories of HMT, KIRLOSKAR, PRAGA, BATLIBOI, BFW, GSMT Etc. We are authorised dealer of SECO CHUCKS. We are offering a wide variety of Lathe Chucks. These Lathe Chucks are widely appreciated by our customers for its dimensional accuracy and effective functioning.

...more

Horizontal Boring Mill

The various mechanisms are enclosed and all the external surfaces are smooth and easily cleaned. The massive construction is a guarantee to withstand fully all the working stresses. The design of the Boring Machine is a guarantee of stiffness, accuracy and large output.The casting is done with the mixture of 25% steel etc and seasoned for at least six months to have proper Brinnel Hardness.Longitudinal & CrossTable Traverse, Vertical travel of Headstock and Boring Stay Support are provided with Rapid Movements as well as Feeds.The main Bed ways and Pillars etc. are accurately finished with Grinding Machine.Headstock and Boring Stay Support both travel simultaneously.

...more

Horizontal Boring Machine

Rajindra all geared Horizontal Boring, Drilling & Facing Machine is a typical machine tool for soughing and finishing operation within the range of Boring, Drilling, Facing & Milling. It is capable of the widest application and is recommended for almost all classes of work. The machine is real achievement, for its leads directly to improve accessibility and simplified maintenance and makes it easy to produce a quality machine tools matched to the needs of the factory for which it is intended. The various mechanisms are enclosed and all the external surfaces are smooth and easily cleaned. The massive construction is a guarantee to withstand fully all the working stresses. The design of the Boring Machine is a guarantee of stiffness, accuracy and large output. The casting is done with the mixture of 25% steel etc and seasoned for at least six months to have proper Brinnel Hardness. The machine is manufactured to Grade-1 limits of Accuracy. The main Bed ways and Pillars etc. are accurately finished with Grinding Machine. Longitudinal & CrossTable Traverse, Vertical travel of Headstock and Boring Stay Support are provided with Rapid Movements as well as Feeds. All gears are precision cut to ensure smooth and silent running. Headstock and Boring Stay Support both travel simultaneously. The machine is manufactured according to Dr. Schlesinger's acceptance test chart. Special Arrangements : To set Rotary table perfectly at right angle. Safety Clutches : To Disengage : Facing Mechanism Sliding Mechanism of Cross Slide. Circular Table Movement Spindle Rod Longitudinal Movement. Spindle Rod Support Guide for vibration control. Boring head height setting adjustment by hand operated wheel fitted at the end of feed gear box motor. Hand operated lever attached to Headstock drive motor. Hand operated lever attached to Headstock drive motor and feel gear box for safe engagement of speed & feed respectively. Centralized control for easy operation.

...more

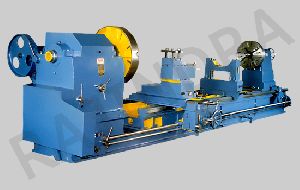

HEAVY DUTY LATHE SERIES MACHINE

Double Chuck Lathe Machine

Heavy Duty Lathe Machines

shapers

Slotters

milling Machines

Special Purpose Machine

Be first to Rate

Rate ThisOpening Hours