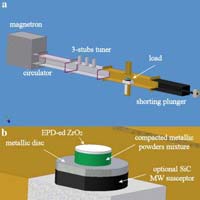

Single Mode Microwave System

We are an acknowledged Manufacturer and Supplier of Single Mode Microwave System in Bengaluru, Karnataka. The system, we offer, is recommended for the study of dielectrics. Quality, precision, compliance, and durability are some of the best attributes of the system that we offer. Its quality assurance is met under the supervision of our team of hawk-eyed professionals. Moreover, the demand for customization is very well entertained by us. Details :Sintering of various samples in a Single mode Microwave applicator is not only very interesting but also challenging for various reasons. It can also be referred to as the process of heating materials inside the “Waveguide”. For the fact that Enerzi has developed over years an in-depth study of the science of Microwave Heating and its various behavior patterns, it can design and develop state of the art Single Mode Microwave Sintering Applicators. In most cases, the application is to study material properties. However, it does not restrict us from exploiting the advantages of single Mode system for other applications like welding, joining and sintering of metals and ceramics.

...more

Microwave Vacuum Ovens

Ours is a name to rely upon whenever looking for Microwave Vacuum Ovens of the finest grade. We are one of the accomplished Manufacturers and Suppliers of Microwave Vacuum Ovens from Bengaluru, Karnataka. These state-of-the-art ovens, when used in the right way, can result in the best dual effect, i.e., of microwave and of vacuum. They work with Vacuum levels of 0.1 Bar to 0.001 Torr efficiently. And as far as the quality of the ovens is concerned, we do not leave any scope for doubts as we conduct various tests to warrant quality.

...more

Microwave Systems for Waste Material Processing

Microwave Systems for Waste Material Processing Waste materials have been become the talk of every town today. Waste exists in many forms today, which includes Solid Waste, Medical Waste and E-waste and many more. Most of these waste materials can be effectively processed through the use of Microwave Energy. Using microwave energy for these processes gives the process multiple advantages. Enerzi has been working rigorously in developing processes and technologies to recycle waste into some useful form of energy. Rubber and Biomass Waste has been the key materials on which the process has been demonstrated. The results seen from the study so far suggest that Microwave has a lot of significant advantages for waste processing over other methods.

...more

Microwave System for Waste Material Processing

We are emerging as the #1 Manufacturer and Supplier of Microwave System for Waste Material Processing in Bengaluru, Karnataka. Microwave System for Waste Material Processing of ours is akin to the ideal systems demanded by the industries for such task. It is made of high-grade materials and components, using ultramodern manufacturing techniques. Its finishing is done in an impeccable manner, where emphasis is being laid on preciseness and quality.Details :Waste materials have become the talk of every town today. Waste exists in many forms today, which includes Solid Waste, Medical Waste and E-waste and many more. Most of these waste materials can be effectively processed by Microwave Energy. Using microwave energy for these processes gives the process multiple advantages. Enerzi has been working rigorously in developing processes and technologies to recycle waste into some useful form of energy. Rubber and Biomass Waste have been the key materials on which the process has been demonstrated. The results seen from the study so far suggest that Microwave has many significant advantages for waste processing over other methods.

...more

Microwave Polymer Curing Ovens

Microwave Polymer Curing Ovens that we offer are manufactured as per the set industry standards under the keen observation of experts. These ovens are subjected to stringent quality tests so as to ensure that only the defect-free product reaches the customers’ end. Sturdy construction and longer functional life are the few words that better describe our ovens.Details :The application of microwave heating to polymers and polymeric composites has been pursued worldwide over the past three decades. Microwave processing offers many advantages over conventional thermal processing. Rapid volumetric heating in microwave processing would significantly reduce cycle times and additionally, since power is applied directly to the material, the need to heat processing equipment is avoided and energy requirements are further reduced. Microwave Curing Ovens are fast making their way into industries and replacing the conventional ovens like electrical ovens and gas/oil fired ovens. Typical applications in Industry include Resin Bonded Abrasives and Composites used in Aerospace industry.Enerzi offers two important variants of Microwave Polymer Composite Curing Ovens viz. Batch and Conveyor systems.Salient Features : Throughput ranging from 50 to 500 kg/hour Typical Cross Section of 200 to 300mm (W) and 150 to 250mm (H) Hot Air Circulation of 100 to 1000 cfm at 200 to 300 deg. C Maximum Process Temperature from 100 to 400 deg. C Hot Air and Product Temperature Monitoring Installed Microwave Power of 1.45 kW to 29 kW Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Conveying System with speed controls from 2 to 50 m/min Highly integrated Interlocks Industrial PLC with touch screen controls

...more

Microwave Plasma System

We bring to afore the best quality Microwave Plasma System for R&D establishments and educational institutes. We are bracketed with the foremost Manufacturers and Suppliers of Microwave Plasma System in Bengaluru, Karnataka. High performance, innovative design, and flawless compilation are some of the virtues of the Microwave Plasma System that we offer.Details :Nano-powder synthesis can be achieved through several means and using Plasma for this process has been the latest development. Amongst this, further, Microwave Plasma route for nano-powder synthesis is very nascent and encouraging. Microwave Plasma Systems are unique in the context that they use lesser power and generate a more effective plasma zone for nano-powder synthesis. There is an elaborate work done on this subject to establish that the end-products (nano-powders), arising out of this method, are much better in quality and the yield is far better as compared to other methods. Enerzi is proud to have developed these systems for Research and Development Establishments and for Educational institutes.

...more

Microwave Glass Melting Furnace

We are counted among the top-notch Manufacturers and Suppliers of Microwave Glass Melting Furnace in Bengaluru, Karnataka. The Microwave Glass Melting Furnace that we offer is designed and manufactured specially for replacing current energy intense heating methods. The furnace’s fineness is attributed to our expertise in manufacturing it flawlessly. Its quality is assured by us, leaving our clients with no doubts on the performance of furnace. Details :Glass Melting or in other words Glass Making is an energy intensive process and a high volume of glass is made and consumed around the world. Microwave Technology in combination with conventional resistance heaters has been developed by us and tested in co-operation of CGCRI (Central Glass and Ceramics Research Institute), Kolkata. There has been a great amount of work done in other parts globally to demonstrate that Microwave Heating can be effectively used to Melt Glass in large capacity at industrial scale. The efficiency of Microwave Heating makes it an excellent replacement for the current energy intense Heating Methods. We at Enerzi believe that this application needs no speaking and would speak for itself. Microwave Glass Melting also offers a large number of operational benefits too.

...more

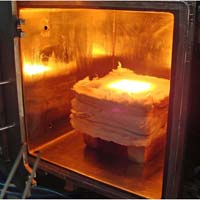

Microwave Furnace for Sintering

Our Microwave Furnace for Sintering is reckoned exemplary furnace for sintering of powder, metals & alloys. It is chiefly demanded by defence labs. The furnace’s attributes are enormous, including fine finishing, high quality, and durability. We are emerging as the promising Manufacturer and Supplier of Microwave Furnace for Sintering in Bengaluru, Karnataka. We can offer it befitted to the client’s specific requirements. Details :Sintering of Powder Metals is not a new science to the world. However sintering of powder metals using the microwave technology is indeed a new development. Research Establishments around the world have done substantial work in the area of Microwave Sintering of Powder Metals and proven that it has its unique advantages. We have been successful at Enerzi in demonstrating the process and have built several furnaces to suit the requirements of different customers. Defense labs are one of the key users of this technology.

...more

Microwave Drying Ovens

Microwave Drying Ovens that we offer are manufactured using the latest techniques under the strict vigilance of experts. These ovens are tested on various quality parameters prior to their final dispatch. We are one of the leading Manufacturers and Suppliers of Microwave Drying Ovens. Supplied only after the completion of stringent testing procedures, our Microwave Drying Ovens are the perfect option for the buyers. Details :The microwave drying oven has been developed and evaluated for potential use as an alternate method of drying. The accelerated drying rate achieved in this method, suggested that microwave drying technique is well suited to industrial applications in drying. Microwave drying provides an alternative to traditional drying methods. Enough work has been done to demonstrate the great advantage of microwave drying both at labscale and at industrial production level around the world. Typical drying applications include drying of Carbon Blocks, Ceramic Products, Fruits & Vegetables, Food Grains & Wood with treatment. One of the greatest advantages that Microwave Drying offers as against the traditional methods is the rapid rate of drying. Combining Microwave Heating with some of the traditional methods gives added advantages of both methods. Salient Features : Throughput ranging from 100 to 2000 kg/hour ( 1 to 20 Tonne / Day) Typical Cross Section of 400 to 1500mm (W) and 150 to 200 mm (H) Typical Length Of the System ranges between 2 to 15 meters Exhaust Air Circulation of 100 to 1000 CFM Maximum Process Temperature from RT to 120 deg. C Product Temperature Monitoring through Suitable Sensor Installed Microwave Power of 5 kW to 100 kW Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Conveying System with speed controls from 2 to 25 mm/sec Highly integrated Interlocks Industrial PLC with User Friendly controls

...more

Microwave Disinfestation System

Microwave Disinfestation System that we offer is well tested and therefore, is the perfect option on which buyers can easily rely. It is precisely manufactured using quality approved basic material under the proper guidance of experts. We are one of the prominent Manufacturers and Suppliers of Microwave Disinfestation System. It can be obtained from us at the best market price.Details:Microwave Disinfestaton is a process of exposing the Rice Grains to Microwave Radiation in a closed system to ensure the rapid killing of all the pests and larvae including the egg stage infestation. Because of a unique property of in-depth penetration of microwaves into the core of food grain, the infestation is eliminated from the core and eradicated from arising again. Typically the disinfestation is done on loose Rice in a conveyor system and after the process it is packed in moisture proof packaging. Alternatively the system can be designed to process the rice in packed condition to avoid further infestation during handling.Enerzi Microwave Systems Pvt. Ltd. has in collaboration with DFRL Mysore developed a completely innovative disinfestation product line incorporating Microwave Technology which has proven to : Increase the shelf life of Rice from current shelf life to 18-24 months. Retain the nutrients and moisture (Food Value) with which it is needed to be preserved Last of all ensures 100% mortality towards regeneration of microbial and burrowing pests. Salient Features : Throughput ranging from 100 to 2000 kg/hour ( 1 to 20 Tonne / Day) Typical Cross Section of 400 to 1200mm (W) and 150 to 200 mm (H) Typical Length Of the System ranges between 2 to 10 meters Exhaust Air Circulation of 100 to 1000 cfm Maximum Process Temperature from 40 to 60 deg. C Product Temperature Monitoring through Suitable Sensor Installed Microwave Power of 2.9 kW to 29 kW Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Conveying System with speed controls from 2 to 50 mm/sec Highly integrated Interlocks Industrial PLC with User Friendly controls

...more

Microwave Chemical Synthesis Ovens

Microwave Chemical Synthesis Ovens that we offer are manufactured and tested using the latest techniques with the objective of eliminating each and every possibility of defect. Sturdy construction and longer functional life are some of the attributes that make our Chemical Synthesis Ovens highly popular. These ovens can be obtained from us at the most reasonable prices.Details :Microwave Chemical Synthesis is the process of applying microwave radiation to chemical reactions to synthesize new chemicals. Microwaves act as high frequency electric fields and will generally heat any material containing mobile electric dipoles/charges such as polar molecules in a solvent or conducting ions in a solid. Polar solvents are heated as their component molecules are forced to rotate with the field and lose energy in collisions. Semiconducting and conducting samples heat when ions or charges within them form an electric current and energy is lost due to the electrical resistance of the material. Microwave heating in the laboratory began to gain wide acceptance following papers in 1990s.Conventional heating usually involves the use of a oven or oil bath, which heats the walls of the reactor by convection or conduction. The core of the sample takes much longer to achieve the target temperature, especially when the substance is a solid.Microwave heating is able to heat the target compounds without heating the entire furnace or oil bath, which saves time and energy. It is also able to heat sufficiently thin objects throughout their volume (instead of through its outer surface), in theory producing more uniform heating. However, due to the design of most microwave ovens and to uneven absorption by the object being heated, the microwave field is usually non-uniform and localized superheating might occur. To counter this limitation often some kind of agitation arrangement is used; either to agitate the field or to agitate the compound as demanded by the process.Microwave heating can have several benefits over conventional ovens : Reaction rate acceleration Higher yield Lower energy usage Different reaction selectiveness Enerzi offers a specially designed Microwave Chemical Synthesis Oven for research and production alike Salient Features : Effective Batch size of 100 ml to 500 ltrs Maximum Process Temperature upto 350 deg.C Contact Type Temperature Monitoring Controlled Magnetic Stirrer for agitation Specially designed condensation system Installed Microwave Power of 0.5 kW to 29 kW Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Highly integrated Interlocks State of the Art Process Control using High End PID controller Industrial PLC with touch screen controls Inert/Reducing/Oxidizing Atmospheric Processing

...more

Infrared Shock Ovens

Our Infrared Shock Ovens are the best choice for efficient pre-vulcanization of profiles and hoses. The company is a proficient Manufacturer and Supplier of Infrared Shock Ovens. Our Ovens are about 1 meter long and have a heating capacity of about 30 kW. Owing to our brilliant logistics network, we are capable of delivering bulk orders of the Ovens within the stipulated time. One can obtain the Ovens at reasonable rates. Details : For high temperatures like 1850°C, the new Infrared Shock tunnel is highly efficient for the pre-vulcanization of profiles and hoses. Arranged between the rubber extruder and the continuous vulcanization line the high power infrared radiation pre-cures the surface of the rubber products. This is related to a better dimension stability and an excellent surface quality This process is ideally suited for sponge profiles, but solid profiles derive an equally useful advantage as well

...more

Hot Air Ovens

We are a successful Manufacturer and Supplier of Hot Air Ovens. The Hot Air Ovens we make available are used especially for post curing of rubber profiles, insulation hoses and other products. We manufacture the Ovens using quality approved components and advanced technology. Bulk orders of the Ovens are processed by us as per the specific requirements of the buyers. We offer the Ovens at nominal rates. Details : Hot Air Tunnels unlike their counterparts i.e. Microwave Ovens or Shock oven do not have any high frequency heating The Ovens have forced heated air circulation with the help of a blower The Ovens are similar in design to the Microwave Tunnel Ovens and serve the purpose of final curing / Post curing of rubber profile after initial curing in Microwave Oven / IR oven.

...more

High Temperature Microwave Sintering Furnace

We are an eminent Manufacturer and Supplier of High Temperature Microwave Sintering Furnaces. The Microwave Sintering Furnaces we make available come with digital display of power and temperature and non-contact temperature monitoring. We hold the expertise of delivering bulk orders of the Microwave Sintering Furnaces within the promised timeframe. Details : This is an advanced Microwave Sintering Furnace with State-of-the-Art Control system and high microwave power to sinter larger samples. We recommend this system for users who have graduated with their basics in Microwave Sintering and want to move on to the level Industrial Microwave Sintering Applications. This system enables the user to sinter a broad range of materials in varied atmospheric conditions, it ideally suits industries looking at replacing their current heating systems with microwave sintering furnaces, AND hence it serves as a perfect bridge between lab experiments and industrial production. Salient Features : Throughput of the furnace ranging from 50 to 1000 kg/day Typical Cross Section of 200 to 1000mm (W) and 150 to 400mm (H) Maximum Process Temperature upto 1700 deg.C Non-Contact Temperature Monitoring Installed Microwave Power of 5.8 kW to 250 kW Conveying System with controls for Speed and position Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Highly integrated Interlocks State of the Art Process Control using High End PID controller Industrial PLC with touch screen controls Inert/Reducing/Oxidizing Atmospheric Sintering

...more

Rubber Cutting Machine

Rubber Cutting Machine finds extensive usage in cutting the rubber profile to the final lengths. The cutting process can be carried out on the rubber profile that is coiled on a spool. We make available Rubber Cutting Machine in different variants such as Manual, Semi-Automatic and Fully automatic Cutting Machines. These machines use precise pneumatic controls for cutting the rubber profiles. One can obtain the machine from us at a very reasonable price.

...more

Continuous Microwave Sintering Furnace

The company is a distinguished Manufacturer and Supplier of Continuous Microwave Sintering Furnaces. The Microwave Sintering Furnaces offered by us have highly integrated interlocks. We maintain a large stock of the Sintering Furnaces in our spacious warehouse, to meet the bulk and urgent requirements of the buyers. One can obtain the Furnaces at reasonable rates from us. Details : This is a full-fledged advanced continuous Microwave Sintering Furnace with State-of-the-Art Control system and Patented Conveying system. As it clearly indicates this is a product meant for the industries as an alternative furnace for production/manufacturing of Ceramic and powder metal parts. We recommend this product for users who have validated their process with Microwave Technology either themselves or by an R&D outfit or from our Application Development Center. This product also demands a trained team to effectively utilize the advantages of Microwave Sintering and hence we work in close synchronization with your production team to make sure that you get the best results from our system. Salient Features : Throughput of the furnace ranging from 50 to 1000 kg/day Typical Cross Section of 200 to 1000mm (W) and 150 to 400mm (H) Maximum Process Temperature up to 1700 deg.C Non-Contact Temperature Monitoring Installed Microwave Power of 5.8 kW to 250 kW Conveying System with controls for Speed and position Step-less Power Control using Microcontroller Module Digital Display of Power and Temperature Highly integrated Interlocks State of the Art Process Control using High End PID controller Industrial PLC with touch screen controls Inert/Reducing/Oxidizing Atmospheric Sintering

...more

Coil Winding Machine

Coil Winding Machine finds wide usage in cases when the rubber profile is produced from the vulcanization line in full length of 50 or 100 meters. Coil Winding Machine is manufactured in such a way that it functions properly with rest of the vulcanization line. We make available Coil Winding Machine with different specifications based on the requirement of rubber Profile size, capacity of the spool etc.

...more

Caterpillar Rubber Hose Machine

Caterpillar Rubber Hose Machine helps in retaining the tension of rubber profile along the vulcanization line. It is manufactured keeping in mind the speed of production and profile sizes. We make available Caterpillar Rubber Hose Machine from 36” to 100” belt length and even higher. Our Caterpillar Rubber Hose Machine suits a variety of rubber profile manufacturing lines. It can be obtained from us at the best market price.

...more

Microwave Disinfestation Systems

caterpillars

Power Supply

Cutting Machine

Infrared Shock Oven

Magnetrons

Amc Services

Design & Consultancy Services

Be first to Rate

Rate This