Ultra Heat Resistant Conveyor Belt

Ultra Heat Resistant Rubber Conveyor Belt We offer UHR Grade Conveyor Belts used for handling material Above 200° Centigrade for fines 200° Centigrade and Lumps upto 220° Centigrade for coarse material. Maximum Intermittent Temperature upto 220 These belts are mainly used for conveying Coke, Sintered ore, Pellet and Clinker Etc. Special features: 1) Excellent heat resistant and abrasion resistant cover rubber compound.2) Recommended to protect conveyor belt from surface cracking and hardening by heat.3) Specially heat-treated and dipped fabric to minimize carcass shrinkage by heat ageing.4) High wear and Tear resistance properties

...more

Rough Top Conveyor Belt

We offer special Rough Top Conveyor Belts in which top surface is made of wear-resistant rubber has rough impression, thousands of flexible gripping fingers provide superior grip to hold packaged products or units being carried up or down with Higher Inclination Angle upto 35 Degree,Rough Top Belts mainly used to transporting light weight goods, such as sacks, boxes and parcels,packagesbags on steep inclines thereby preventing slippage. It has a cushioning effect, mollifies and absorbs vibrations. We offer in Two ply and three ply in cut Edge Construction in carcass type of NN and EP fabric. We offer in Two ply and three ply in cut Edge Construction in carcass type of NN and EP fabric APPLICATION • Used in transportation of light weight goods on inclined surfaces.• Package handling, labeling BENEFITS & FEATURES • Provides excellent grip between belt top Surface and packages.• Commonly used Black cover for utility applications• Creates less friction coefficient• Perfect for running over table and flat panel• Special Mesh-like pattern generates the relief effect• Absorbs vibrations, preventing material slippage• Odorless, nontoxic, non-marking• These belts mostly used flight loaders and lorry loaders

...more

Oil Resistant Conveyor Belt

We offer oil and grease resistant conveyor belts specifically designed to convey different types of materials that contain any kind of oil and fat, it will not effected by paraffin oil, naphthene oil, gasoline animal or vegetable fats, etc. Conveyor Belts are used to Convey Different types of Raw materials, The Raw Materials which contains Oil & Fat, Like Poultry Feed, Fish Feed, Soybean Draff, Packed Fish, Meat Products etc , damage the belt and penetrates Oil and Fat into the rubber causing it to swell and distort, resulting in lack of performance life of the belt and serious operational problems. We offer oil and grease resistant conveyor belts specifically designed to convey different types of materials that contain any kind of oil and fat, it will not effected by paraffin oil, naphthene oil, gasoline animal or vegetable fats, etc. These Belts are specially constructed with Nit rile Butadiene Rubber (NBR) with Polymer that is resistant to oil and grease and provides higher performance life of the Conveyor Belt. These Belts are made of cotton, nylon and EP Fabric finished through the processes of calendering, assembling, vulcanizing , These belts are widely used in various industries such as the chemical and fertilizer industry, wood, paper and pulp, sugar and food, transshipment and recycling plants.â�¨â�¨ We offer two types of oil-resistant rubber conveyor belt 1) Oil and Fat resistant Rubber Conveyor Belt – for products which contains paraffin oil, naphthene-based oils, petrol animal or vegetable fats etc ,These belts are mostly used in Soybean draff , Fish meat , concrete and Batching plants , Mineral processing plants, waste sorting and compost machine ,Timber industry and sawmills, paper and Corn Industry ,Solvent Extractions Plants. 2) Oil and Heat resistant Rubber Conveyor belt /Elevator Belt- for products which contain oils and heat – Like Soya been Plants to Carry DOC ,Bitumen plants , Hot Mix Plants , We offer Heat & Oil Resistance up to Temperature of 180 C

...more

Magnetic separator Belts

We offer Cleted Magnetic separator Belts that revolve around a magnet that is suspended over a conveyor belt, these belts mainly used for the separation of magnetic and non-magnetic parts of the base material being conveyed, it is used in cement, glass and rubber-tire recycling plants, which extract Ferromagnetic and weakly-magnetic metals from product flows. Applications areas - Coal Handling plant, Steel Recycling Plants, Concrete Recycling Plants, Food Processing Plants, Recycling material such as trash, glass, aluminum, and tires Solid waste facilities We offer variety of magnetic separator belts- Heavy-duty rubber belt with hot vulcanized rubber cleats Heavy duty rubber belt with stainless steel angle iron mounted cleats

...more

Magnetic Conveyor

We offer Cleated Magnetic separator Belts that revolve around a magnet that is suspended over a conveyor belt, these belts mainly used for the separation of magnetic and non-magnetic parts of the base material being conveyed, it is used in cement, glass and rubber-tire recycling plants, which extract Ferromagnetic and weakly-magnetic metals from product flows, These belts are compounded with rubber.Heavy-duty rubber belt with hot vulcanized rubber cleats, Heavy duty rubber belt with stainless steel angle iron mounted cleats.

...more

M24 GRADE RUBBER CONVEYOR BELT

We offer Wide range of Grade M-24 Conveyor Belts suitable for conveying normal temperature material maximum up to 60 Degree, it is constructed with fabric (Carcass) and rubber Compound, rubber cover is compounded from the best quality Natural rubber which provides superior resistance to cutting and gouging to Load Support and convey different type and size of material, from short to long distance and light to heavy load transportation of materials.These belts are mainly used in all the process industries to carry different materials such as Fertilizer Plants -Super phosphate in lump and powder), Cement Plants-limestone, Clay slacked lime, sand,Cold clinker Steel & Power Plant -Coal,Coke, ashes and crushed metallic oresStone Crushing Industries -Granite & Blue metal,Crushed stone. Biomass Power Plant -biomass fuels, wood chips, paper bales, gravel, sized coke, Glass Industries-timber crushed glass, granite, all types of slacks, sandstones, chipping, quartz, stackers and reclaimers.

...more

Heat Resistant Rubber Conveyor Belt

Heat Resistant Conveyor Belts Heat Resistant Belts have found wide acceptance in various Industries , heat resistant belts are required for transporting materials above temperature of 60°C. It is used for handling Material Like Sinter ,Coke, Phosphate and Clinker etc).As per Indian Standard, We Have Heat resistant belts in four different types which has been categorized as below. HR – T1 (suited upto 120 Deg C)HR – T2 / SHR (suited upto 150 Deg C)HR – T3 /UHR (suited uptp 200 Deg C)Pyroshield 250 (suited upto 250 Deg C)Pyroshield 300 (suited upto 300 Deg C) HRT1 Heat Resistant Grade Belts • HR(T1) - Our range of HR (T1) Conveyor Belts are suitable to convey material in continuous Temperature of 125 degree centigrade for coarse materials and 100 degree Centigrade for fines. Maximum Intermittent Temperature upto 125 mainly used in Paper, Foundries, Chemical & Fertilizer plants etc. SHRT2 Heat Resistant Grade Belts • SHR (T2) - Our range of SHR (T2) Conveyor Belts are suitable to convey material up to 125 degree centigrade for fines and 150 degree centigrade for coarse material. Maximum Intermittent Temperature upto 150 ,These Conveyor belts are mainly used for conveying Sintered ore, Pellet, Coke, and Clinker Etc. SHRT3 Grade Heat Resistant Conveyor Belts Our range of SHR(T3) Grade Conveyor Belts are used for high temperature applications, it is suitable to convey material in continuous Temperature of 150 degree centigrade and a peak temperature of 180 degree centigrade. Maximum Intermittent Temperature upto 180 These conveyor belts are mainly used to handle red hot materials such as Cement, Clinker, Sintered Ore and Phosphate. Recommendations:The Service and Performance Life of Heat resistance Belts mainly depends on Proper Selection as per Temperature of Conveying material and Construction of Belt, But there is also other factors involving which can minimize the performance, Like wear properties of the materials, the fall during loading, the size of the material, the length of the belt, the speed of the conveyor and any chemical action which may be involved. Higher thickness of the cover is also essential because the cover acts as a barrier between the heat source and the carcass.

...more

heat resistant belt

Heat Resistant Belts have found wide acceptance in various Industries , heat resistant belts are required for transporting materials above temperature of 60°C. It is used for handling Material Like Sinter ,Coke, Phosphate and Clinker etc).• HR(T1) - Our range of HR (T1) Conveyor Belts are suitable to convey material in continuous Temperature of 125 degree centigrade for coarse materials and 100 degree Centigrade for fines. Maximum Intermittent Temperature upto 125 mainly used in Paper, Foundries, Chemical & Fertilizer plants etc.

...more

Food Grade Conveyor Belts

We offer Food Grade hygienic Conveyor Belting Which confirm to IS:1891 (Part IV), Food grade belts are suitable for handling food materials, These belts are made from natural rubber, special raw material, Chemicals and without Carbon ,It do not transfer any odour or colour to the Conveying food products ,These belt are mostly used in sugar industry, tea industry, tobacco, grain , pharmaceuticals, tea industries in Conveyor and Elevators.

...more

Food Grade Belt

We offer Food Grade hygienic Conveyor Belting Which confirm to IS:1891 (Part IV), Food grade belts are suitable for handling food materials, These belts are made from natural rubber, special raw material, Chemicals and without Carbon ,It do not transfer any odour or colour to the Conveying food products ,These belt are mostly used in sugar industry, tea industry, tobacco, grain , pharmaceuticals, tea industries in Conveyor and Elevators.

...more

Fire Resistant Rubber Conveyor Belt

Fire Resistant Conveyor Belts are recommended for internal transportation within tunnels and coal mines where the material is exposed to flame and there are chances of fire hazards. Its is Suitable for handling Coal, Coke, and other fire prone materials. In Fire Resistant belts the rubber covers are anti-static and fire resistant confirmed to international standards Specially compounded with Neoprene and SBR, which prevent fire from spreading over the entire belt, These belts are made to comply with the CSA standard CAN/CSA-M-422-M87 Grade and Indian Standard IS 1891 Part V. It has Static conductivity and passed through drum friction test, it contains high heat & wear Resistance properties and Suitable to perform in temperature of -30 degree to + 50 Degree , FR belt are largely used in thermal power plants, mining industry, coal handling plants, wood, paper & pulp, sugar & food, recycling and chemical & fertilizer plants. We offer these belts as per the specific requirements of client.

...more

Fire Resistant Conveyor Belt

Fire Resistant Conveyor Belts are recommended for internal transportation within tunnels and coal mines where the material is exposed to flame and there are chances of fire hazards. Its is Suitable for handling Coal, Coke, and other fire prone materials. In Fire Resistant belts the rubber covers are anti-static and fire resistant confirmed to international standards Specially compounded with Neoprene and SBR, which prevent fire from spreading over the entire belt, These belts are made to comply with the CSA standard CANCSA-M-422-M87 Grade and Indian Standard IS 1891 Part V. It has Static conductivity and passed through drum friction test, it contains high heat & wear Resistance properties and Suitable to perform in temperature of -30 degree to + 50 Degree ,

...more

fire resistant belts

Fire Resistant Conveyor Belts are recommended for internal transportation within tunnels and coal mines where the material is exposed to flame and there are chances of fire hazards. Its is Suitable for handling Coal, Coke, and other fire prone materials. In Fire Resistant belts the rubber covers are anti-static and fire resistant confirmed to international standards Specially compounded with Neoprene and SBR, which prevent fire from spreading over the entire belt, These belts are made to comply with the CSA standard CANCSA-M-422-M87 Grade and Indian Standard IS 1891 Part V. It has Static conductivity and passed through drum friction test, it contains high heat & wear Resistance properties and Suitable to perform in temperature of -30 degree to + 50 Degree , FR belt are largely used in thermal power plants, mining industry, coal handling plants, wood, paper & pulp, sugar & food, recycling and chemical & fertilizer plants.

...more

Endless Conveyor Belt

We offer Hot Vulcanized Endless Conveyor belts upto the width of 2400MM in all the types and Grades of Conveyor belting, Like M-24 Grade Endless Conveyor Belt, Heat Resistant Endless Conveyor Belt, Ultra Heat Resistant Endless Conveyor Belts, Rough top endless Belts and Chevron Endless Belts , Weigh Feeder Endless Belts etc.

...more

Conveyor Belt

Heat Resistant Belts have found wide acceptance in various Industries , heat resistant belts are required for transporting materials above temperature of 60°C. It is used for handling Material Like Sinter ,Coke, Phosphate and Clinker etc). As per Indian Standard, We Have Heat resistant belts in four different types which has been categorized as below. • HR(T1) - Our range of HR (T1) Conveyor Belts are suitable to convey material in continuous Temperature of 125 degree centigrade for coarse materials and 100 degree Centigrade for fines. Maximum Intermittent Temperature upto 125 mainly used in Paper, Foundries, Chemical & Fertilizer plants etc.

...more

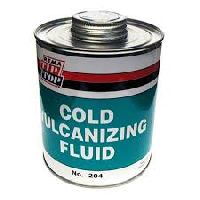

cold vulcanizing solution

We are distributors and suppliers of different types of rubber conveyor belt joining solution cement made by renowned manufacturers known for premium quality and durability , We offer Belt Jointing Solution for M-24 Grade Rubber Conveyor Belts, Heat Resistant rubber Conveyor Belts,SAR Grade,Fire Resistant Belts, Pulley Lagging,Tank Lining etc. Clean Belt Surface - Buff the surface remove all dust, oil, moisture, grease etc. Stir Shakewell solution cement before use and mix hardner 100 : 6 uniformly in solution.Apply by brush the mixture of solution compound, Apply the first coat of the HARDNER mix solution and let it dry completely.Now apply second thin coat and let it dry 15-20 Minutes , support the bonded area with solid wooden ply or m.s. plate. Now bring both surfaces together. Hammer hard with a wooden hammer, ensure air bubble is trapped jointing area.

...more

Chevron Conveyor Belts

We offer Chevron Conveyor Belting which is used in the application where the Inclination angle is too high and the conveying material is rolling back, we are offering Chevron Conveyor belting (Cleated Belts) to prevent the material from sliding backwards. The special profiles of Chevron belt make increased angles by which inclination is possible and packed and unpacked material can be convey very easily and effectively as compared with smooth surface belts , Our Chevron Belt inclined upto 35-40 Degree ,With 15mm Cleat height in V,Y,U PROFILS ,Cleat angle and pitch are designed for smooth travel over return idlers ,it is mostly used to convey loose material like sand, fine coal and grain materials it is also used in concrete batching plants, stone quarries, road scalpers, truck wagon loading system, Our Standard widths 500 mm wide to 1200 MM wide (higher width can be offered on request.

...more

Chevron Belts

We offer Chevron Conveyor Belting which is used in the application where the Inclination angle is too high and the conveying material is rolling back, we are offering Chevron Conveyor belting (Cleated Belts) to prevent the material from sliding backwards. The special profiles of Chevron belt make increased angles by which inclination is possible and packed and unpacked material can be convey very easily and effectively as compared with smooth surface belts , Our Chevron Belt inclined upto 35-40 Degree ,With 15mm Cleat height in V,Y,U PROFILS ,Cleat angle and pitch are designed for smooth travel over return idlers ,it is mostly used to convey loose material like sand, fine coal and grain materials it is also used in concrete batching plants, stone quarries, road scalpers, truck wagon loading system.

...more

bucket elevator belt

We are a leading manufacturer and supplier of Bucket Elevator belts. We offer bucket elevator belts, which are made from different type of high quality raw materials as per the application requirement especially in the working environment, Bucket Elevator belts are widely used in various processing industries. These products are mainly used for vertical applications to lift material from the lower to the second level where a limited space is available. We are specialist in construction, manufacture and delivery of these belts for over 180m elevation hoists and with operating speeds of @ 1750tph. The great advantages of our elevator belts are less maintenance, extended life and lower operating costs compared to other types of elevator belts. Applications of Bucket Elevator Belts : Sand Mining - Stone Industry, Concrete Plants - Cement Plants, Mineral processing plants, Timber industry and sawmills, Pulses Mills, Flour Mills, Sugar Mills, Rice Mills, Salt mines , Silo feeding , Docks , Ship loading and unloading , Potatoes and Starch factories, Foundries, Waste treatment plants Key Features: Some of the standard key features of these elevator belts include: Available in various tensile strengths from 315 N / mm to 6300 N / mm Constructed with different tensile members such as EP, Kevlar, Cotton, Nylon, Steel Cord Available in complete range of quality cover compounds comprising fire resistant, heat resistant as well as oil resistant finish properties Available in white hygienic food grade finish Comes in low elongation that allows short take-up Features high bolt tear resistance as well as superior fastener strength Comes with superior clamping characteristics Comes with small pulley diameters

...more

rubber conveyor belt joining solution cement

We are distributors and suppliers of different types of rubber conveyor belt joining solution cement made by renowned manufacturers known for premium quality and durability , We offer Belt Jointing Solution for M-24 Grade Rubber Conveyor Belts, Heat Resistant rubber Conveyor Belts,SAR Grade,Fire Resistant Belts, Pulley Lagging,Tank Lining etc. Vulcanizing Process : (1) Clean Belt Surface - Buff the surface remove all dust, oil, moisture, grease etc. (2) Stir / Shakewell solution / cement before use and mix hardner 100 : 6 uniformly in solution. (3) Apply by brush the mixture of solution compound (4) Apply the first coat of the HARDNER mix solution and let it dry completely. (5) Now apply second thin coat and let it dry 15-20 Minutes , support the bonded area with solid wooden ply or m.s. plate. (6) Now bring both surfaces together. (7) Hammer hard with a wooden hammer, ensure air bubble is trapped jointing area. (6) Now the jointed belt is ready for service operation after an hour of rest. (7) The entire process of the cold vulcanizing method should be carried out within 4 - 6 hours and should be carried out by a specialist. PULLEY LAGGING and TANK LINING are also done by same process. This method of cold vulcanizing / bonding is simple, quick, safe and economical. HEAT RESISTANT GRADE APPLIED FOR CONVEYOR JOINT IS FOLLOWED BY THE SIMILAR METHOD AS ABOVE.

...more

chevron belt

We offer chevron conveyor belting which is used in the application where the inclination angle is too high and the conveying material is rolling back, we are offering chevron conveyor belting (cleated belts) to prevent the material from sliding backwards.

...more

Heat Resistant Conveyor Belt

Heat resistant belts have found wide acceptance in various industries , heat resistant belts are required for transporting materials above temperature of 60°c. It is used for handling material like sinter ,coke, phosphate and clinker etc).

...more

Rubber Conveyor Belts

We are engaged in manufacturing, supply and distribution of rubber conveyor belts in india.

...more

UHR Grade Conveyor Belts

We offer uhr grade conveyor belts used for handling material above 200° centigrade for fines 200° centigrade and lumps upto 220° centigrade for coarse material. Maximum intermittent temperature upto 220 these belts are mainly used for conveying coke, sintered ore, pellet and clinker etc.

...moreBe first to Rate

Rate ThisOpening Hours