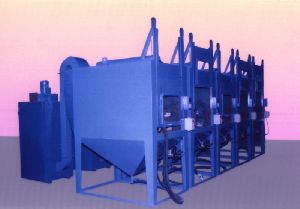

Belt Conveyor Sand Blasting Machine

Get Price Quote

1 Piece (MOQ)

portable abrasive blaster

50,000 - 150,000 Per Piece

1 Piece (MOQ)

Best Deals from Abrasive Blasting Machine

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

portable abrasive blasting machine

Get Price Quote

The portable abrasive blasting has been successfully utilized on glass , metal, plastic , ceramics, and stone. The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. Its functions include descaling, peening , Deburring , Deflashing , polishing, cleaning and stress relieving. The pressure vessels are tested to 250 psig and coded. The portable abrasive blasting machine works on pressure blasting principle, consist of a blast generator. The abrasives/grit/shots are filled at the top of machine when machine is off and blasting pot is not pressurized. A vibrating sieve is provided to sieve the abrasive filled. The mushroom valve is down then abrasive will get transferred to blast storage tank for blasting.The mushroom valve gets up,the compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. Blast nozzles special design and tungsten carbides lined, result in long service life. The remote control ON / OFF is in operators hands and requires no electric connection.There are various types of media that can be used in sandblaster depending on the requirement and the surface that has to be smoothen, roughen or cleaned such as Sand, aluminium oxide, Baking soda, Wood particles, glass beads, steel shots, steel grits, copper slag and many other. Remote Control SystemRemote control system complete ON / OFF control of the machine in the hands of the operator at blast nozzle. It saves abrasive consumption when operator changes position or performs spot blasting and provides added safety to operator and other personnel in the area. Machines fitted with remote control system are designed with "R" such as Macro P7 300R, Macro P7-500R and Macro P7-1000R.

Portable Abrasive Blaster Machine

Get Price Quote

Abrasive Pressure Blast Machine

1,550,000 Per piece

1 piece (MOQ)

Pressure Abrasive Blasting Machine

150,000 Per Piece

Abrasive blast cleaning machines

Get Price Quote

abrasive blasting machines

Get Price Quote

abrasive blasting machines are fabricated out of thick gauge crc sheet metal, sharing and bending and welded to perfection. It can work continuously without stopping for media refills . The surface finish are extremely good as compare to suction sand blasting. It has unique feature of in build dust collector are of its own kind, keeping floor clean and fresh ambient, reduce maintenance and greater productivity.application: used for cleaning engine components like cylinder head, crank case ,tappet cover, manifold and turbochargers parts.

Portable Abrasive Sand Blasting Machine

Get Price Quote

Salient Features : We have in store with us an impeccable spectrum of Portable Abrasive Blasters. Customers can make use of varied media as an abrasive for different activities and finishes. Fabricated in accordance with the set industrial guidelines, our range is available in standard and customized specifications. Recommended for high output on big components like vessels & structures and our P7-501RSPL recommended for Components made of Stainless Steel & Sheet thickness before 4mm.

portable abrasive blaster

29,500 Per Piece

portable abrasive blasting machine

Get Price Quote

1 Unit (MOQ)

Automated Abrasive Blasting Machine

3,800,000 Per Set

1 Set (MOQ)

Portable Abrasive Blaster Machine

Get Price Quote

All standards models of Portable Abrasive Blaster are available with and without Remote Control Version.In five standard models having cleaning rate from 3 to 20 sq-meter/hr.Tungsten carbide venturi nozzles in 5mm, 6mm, 8mm, 10mm, 12mm bore. Air requirement varies as per model from 45 cfm to 250 cfm at 80 psi. 1) Automatic Filling Value :The machine is provided with automatic musroom valve (Filling Valve) for quick refilling of abrasive. 2) Tungsten Carbide Venturi Nozzle :The long & short series convergent-divergent tungsten carbide lined blasting nozzle ensures high velocity, evently distributed blast pattern & higher blasting output and provides lower wear, longer life and greater resistance against breakage. 3) Blast Hose :The blast hose is highly abration resistance with improved mixing valve outlet for longer life, high flexibility with lower bend radius & light weight and electrically antistatic for safe operation. 4) Abrasive Control Valve :The machine is fitted with pinch valve with hand wheel to control the abrasive flow through blast nozzle. 5) Abrasive Sieving :A wirw screen is fitted with pneumatic vibrator to sieve abrasive to avoid blast line choking. 6) Abrasive Tank Construction :Abrasive tank is fabricated from tested quality steel plate in accordance with IS-2825 and hydraulically tested at 250 psi. 7) Automatic Exhaust Valve :It vents outlet air and thereby machine is depressurised instantly. Valve opens automatically with stop of air supply to machine and vice-versa. 8) Air Filter & Pressure Gauge :An online air filter and pressure gauge is provided. 9) Ball Valve :The machine is fitted with ball valve having stainless steel ball (An anti-corrosive material) to ensure full air flow without pressure loss.

Abrasive Blasting Machine

125,000 Per Piece

Cabinet type abrasive blasting machine we are manufacturer of all types of abrasive blasting machines.

portable abrasive blaster

45,000 Per Piece

Vacuum Abrasive Blasting Machine

Get Price Quote

MEC offer portable dust free abrasive blasting equipment with high vacuum power and efficient separation for abrasives & debris. MEC vacuum blasting machines are suitable for different purposes, applications for surface preparation before coating and needs only one man to operate. The blasters are based on pressure vessels in combination with compressed air filters and pressure regulators that ensure sufficient speed of blasting operation in a dust free environment. Abrasive is automatically and instantly recovered for reuse. No flying dust & abrasive to contaminate surrounding. A special valve on pressure vessel allows to work with a blasting pressure as low as 1 bar and as high as 7 bar with the same machine. Vacuum blasting technique can be used on delicate blasting jobs where blasting on low pressures is a must. All MEC vacuum blasting machines comes with a standard special lightweight blast head, blast and vacuum hose assembly, as well as a set of brushes to treat flat surfaces. The very special fibres used in brushes ensure best performance and economy.Our Standard Models MCB-V MCB-X MCB-XV P-14

portable abrasive blasting machine

Get Price Quote

1 Piece (MOQ)

If you are searching for a abrasive blasting device that is portable yet highly functional, select Aerowheel Portable Abrasive Blasting Machine.Therefore, if you also want to get a Portable Abrasive Blasting Machine that can assist you to increase the production quantity of your business, order Aerowheel Surface FinishingPortable Abrasive Blasting Machine. The Machine we offer is prepared with stainless steel and weight 100-1000 kg. The Aerowheel Portable Abrasive BlastingMachine use 220volts unit electricity to work properly. AerowheelPortable Abrasive Blasting Machine is completely run by electricity and no manual labour is required for operating this device because it’s fully automatic. The power usage of this device is 1-3 kilowatt. You don’t need to get concerned about the order quantity of Aerowheel Portable Abrasive BlastingMachine since the minimum order quantity is 1 piece. As Aerowheel Surface Finishing is one of the massive Portable Abrasive Blasting Machine manufacturer, you can get this incredible machine by Aerowheel anywhere in India. You can get Portable Abrasive BlastingMachine in foreign countries too because we export too. Aerowheel Surface Finishing offers Portable Abrasive Blasting Machine at an affordable price that is more cheaper than the other trademarks. Therefore approach to Aerowheel Surface Finishing for receiving the best offers on Portable Abrasive Blasting Machine.

Abrasive Blasting Machine

100,000 - 1,200,000 Per Piece

portable abrasive blasting machine

45,000 Per Piece

1 Piece(s) (MOQ)

TECHNICAL SPECIFICATIONS Model KI-P7 300R KI-P7 500R KI-P7 1000R Special Contractor Abrasive Capacity Metallic (Kg.) Sand (Kg.) Volume (Ltrs) 300 130 85 500 230 142 1000 460 284 600 276 170 Overall Dimensions approx Height (mm) Diameter (mm) Weight (Kg.) 1175 465 142 1375 620 192 1615 765 247 1515 620 205 Blast Nozzle Tungsten Car bide lined Office (mm) (standard size) 6 8 10 10 Blast Hose ID (mm) Blast Hose Length (mtr) Recommended Air Hose ID (mm) 19 5 19 25 10 25 32 10 32 32 10 32 Approx. Cleaning Rate (sq.Mtr/hours) 5-9 11-15 15-19 15-19 Compressed Air Requirement (M3/min) at6.33kg/Cm2 2.4 3.8 7.1 7.1 Recommend Abrasive Size (BSMesh) 25-80 16-80 16-80 16-80 Remote Control Operation Yes Yes Yes Yes

Mobile Vapor Abrasive Blast Equipment

Get Price Quote

EcoQuip 2 EQm Mobile Vapor Abrasive Blast EquipmentCompact, portable blast equipment fits in bed of pickup truck. Compact, fully portable entry-level unitThe built-in hand truck with over-sized wheels makes the EQm easy to move around the jobsite. Don't let the size fool you, this compact blaster is capable of handling any type of project, from cleaning to surface preparation.Fits in the bed of most standard pickup trucksblast pressure ranging from 30-175 PSIOversized wheels for easy portabilityPot size of 3.5 cubic ft - holds approximately (8) 55 lb bags of mediaFeatures:Generates less dust - 92% less airborne dust than dry blastingOptimizes air, water and media ratio – resulting in a fine mist with a blast that is powerful, but with less dustUses less water than traditional water-based wet blastingDesigned for years of solid serviceApplications:Surface PreparationRestorationMarine MaintenanceGraffiti RemovalBlast CleaningIndustries:Professional CleaningMarine & Shipyard MaintenanceHeavy Equipment MaintenanceTraffic Marking & RemovalBridge Construction & MaintenanceConstruction Equipment-MaintenanceHeavy Structural Steel & ConstructionMarineAirports

portable abrasive blasting machine

Get Price Quote

1 Piece (MOQ)

Abrasive Grit Blasting Machine

Get Price Quote

From bulk to retail order fulfillment, we can do it all. Our company has a wide supply chain network to provide our buyers with the product all year round and make timely delivery. To guard our complete range of goods from exterior causes that can be damaging, we have a high-tech packing unit armed with the newest safe packaging technologies and supplies.

portable abrasive blaster

Get Price Quote

abrasive blast equipment

Get Price Quote

abrasive blast equipment, shot peening equipment

PORTABLE ABRASIVE BLASTER:

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving, De

portable abrasive blasting machine

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving, Deflashing and cleaning.Portable abrasive blaster pressure feeds the system of abrasive propelling and results in higher production rates. The pressure vessels are tested to 250 psig and coded. Blast nozzles special design and tungsten carbides lined, result in long service life. It is equipped with high static and low weight blast hose. The remote control ON OFF is in operators' hand and requires no electric connection.

portable abrasive blasting machine

Get Price Quote

We manufacture and offer a wide range of blasting machines including Shot blasting machine, portable Sand blasting machine, tumb & hanger type shot blasting machine, cabinet & suction gun type sand blasting machine, portable sand blasting machine. Along with machines also the abrasives and inspection Instruments, worker safety equipment etc. The range of products include garnet, steel shot, blast system package, coal slag, copper slag, blast nozzles, nozzle holders, helmet air filters, full face masks, airless spray guns, repair kits and guards etc. Before we describe our wide range of portable Sand blasting machine let’s have a look on its features.

portable abrasive blasting machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering portable abrasive blasting machine, sand blasting machines are used for the surface preparation. Abrasive media to be used will be either sand or steel grit depending upon availablity and requirement.

portable abrasive blaster

Get Price Quote

The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. The operation is performed on metals, glass, ceramics, plastic and stone.The machine works on pressure blasting principle, consist of a blast generator. The abrasives are filled at the top of machine when machine is not working and blast generator is not pressurized. At the top, a vibrating sieve is provided to sieve the abrasive filled. The oversize abrasive and debris are retained on the screen, thus prevent the choking of blast line. When mushroom valve is opened the abrasive will get transferred to blast generator for blasting. The mushroom valve gets closed when compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. The Blast Generator is fabricated from MS Steel plate of thickness not less than 6 mm as per IS-2825 and hydraulically tested for 250 psi.