Mold Temperature Controller

80,000 Per Piece

1 Piece (MOQ)

Mold Temperature Controller

Get Price Quote

1 Piece (MOQ)

Best Deals from Mold Temperature Controller

Mould Temperature Controller

Get Price Quote

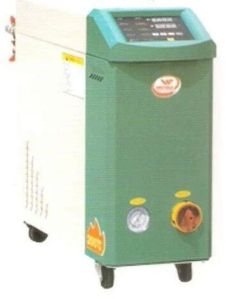

Mould Temperature Controller, provided by us, has advanced microprocessor controller that displays operation and fault status. With this, accurate digital readout of process temperature against set point is also available in our Mould Temperature Controller. Our Mould Temperature Controller is easy to service and maintain. We provide Mould Temperature Controller at market leading rates. Highlights Side panels easily openable Tubular cooling coil Stainless steel heater Reliable and high performance pump Moveable parts in contact with the medium (water) Made of stainless steel Totally safe Dual safety heaters Can handle processing temperature up to 150oC in oil version and up to 90oC in water version Easy to move Mounted on wheels

Mould Temperature Controller

Get Price Quote

Combined Model i.e. Oil & Water in one Compact in Size SS 304 Tank with Insulation Equipped with Castor Wheel

Mold Temperature Controller

Get Price Quote

We are engaged in manufacturing, supplying and exporting a comprehensive array of Mold Temperature Controller. It is mainly used in plastic injection molding machine to control the temperature. Mold Temperature Controller comes with various features such as a mold draining facility, leak stop operation, fault indications, mimic diagram, etc. Mold Temperature Controller is efficient as well as durable.

MC SERIES AUTOMATIC MOULD TEMPERATURE CONTROLLER

Get Price Quote

Range 12-1500Kgs. Main Features : The main machine adopts high efficiency mini hot water pump or oil pump with reliable function, small size and light weight. Adopts imported digital temperature control gauge. Can improve the color of product and stabilize the quality of product. Application: Use in plastic and rubber industry, chemical and pharmaceutical industry, textile industry and any other situation where temperature controlling necessary.Use in producing plastics which high temperature mould necessary and high accuracy necessary.

mold temperature controllers

90,000 - 300,000 Per piece

1 piece (MOQ)

Oil Type Mold Temperature Controllers use water as heating media to realize heat exchange by indirect cooling for standard temperature control can reach 200 degrees while high temperature can reach 300 degrees. Oil type has its superiorities with wide temperature controlled range and excellent heat stability.

Mold Temperature Controller

80,500 - 90,800 Per piece

1 Piece (MOQ)

The mold temperature controller of an injection molding machine helps to control the temperature of the mold with the help of a heat transferring medium like water or oil in this model. Therefore, temperature control ranges within 180. The PID controller used for controlling the temperature with the deviating range of ±0.1℃ with higher operating efficiency and hence, it saves more energy with respect to the electrical billing.

Mold Temperature Controller

70,000 - 250,000 Per Bag

1 Piece (MOQ)

Mold Temperature Controller

Get Price Quote

Focused towards delivering the utmost product range in terms of quality, we conduct frequent quality checks. Rely on us to buy the best in class mold temperature controller; we are a notable Supplier in this domain. Our precision engineered mold temperature controller is available with a tank of capacity 55L.

Mold Temperature Controller

Get Price Quote

We are offering mold temperature controller. Booster pump (for filling under pressure at temperatures of more than 100 °c) touch-screen display, 5.7", windows ce heat exchanger made of stainless steel (incoloy heating element) pump and system pressure gauges maintenance free magnetically coupled pump (standard in the tempro plus d140160180) heating control via solid state relay

Toshiba Mould Temperature Control Unit

Get Price Quote

MOULD TEMPERATURE CONTROL UNIT, 90 deg c with water,150 deg c with oil.Heat Transfer Unit Water/Oil.Insulated Sealed Tank.PID Based Temperature Control.Leak Stop Feature.

Mold Temperature Controller

Get Price Quote

As our Mold Temperature Controllers have gained huge popularity in the global markets, we have become the reliable name involved in its exporting and supplying. Compliant with the set industry standards, our Mold Temperature Controllers are safe to use and highly efficient. Buyers can place with us bulk orders for Mold Temperature Controller and enjoy reasonable prices. No matter what the distance is, our deliveries are always timely!DetailsThe Mold Temperature Controller is used to preheat a Mold / Process to the desired operating temperature by engaging the unit’s electrical immersion heater and re circulating the water in the system.

Mold Temperature Controller

125,000 Per Set

The Automatic mold temperature controller works on heat exchanging principle using water or oil to precisely control the mold temperature, this reduces the production time and thus produces quality product. One of our main objectives is to offer high quality products and to achieve this goal all our products undergo vigorous tests.Two types of Mold Temperature available Water & Oil Mold Temperature Controller

Mold Temperature Controller-Oil Type

70,000 - 500,000 Per Set

1 Set(s) (MOQ)

Mould Temperature Controller

15,222,700 Per Unit

1 Piece (MOQ)

Mould Temperature Controller The mould temperature controller’s main function is to maintain a desired mold temperature setting appropriate for the component and feedstock combination being molded. The mold temperature controller circulates cooling fluid through the mould cooling circuits to provide equilibrium to the heat flux experienced by the mould for every cycle. It is common to run separate mold temperature controllers for each mold half. This set-up allows for greater process control and processability. If a hot sprue is used on the stationary half of the tool to bring the molten MIM feedstock to the parting line, this half of the tool requires a greater amount of cooling, thus having a separate controller here will allow the temperatures of the two mold halves to be more accurately controlled. Key Features : Auto cover flux (granules) feeder. Baffle plate auto Up-Down movement. Mobile cum pillar unit. Operation cycle data print and recording. Rotor shaft coating reminder. Cover flux and nitrogen consumption data.

Mould Temperature Controllers - BTC Series

Get Price Quote

The Bry-Air offer superior quality Mould Temperature Controller BTC series which is designed to maintain constant temperature of Mould during the Moulding process. It is engineered to provide precise temperature control. This technology is increasingly being used to improve the quality of injection moulded parts and to avoid material wastage during injection moulding start up phase. Apart from its functioning it has an exquisite appearance and is small in size, also it is convenient for mobility as the unit is mounted on wheels. Widely demanded in various industries, our range is known for its reliability & accuracy. We provide these in different specifications to meet the diverse demand of customers in different Industries with different application areas worldwide. The state-of-the-art design of our Mould Temperature Controller is seen in high quality injection plastic mould like automobile Industry, medical plastic industry, white goods industry etc. Bry Air Mould Temperature Controller is available in water and oil.The temperature can be maintained between 40 – 90°C in case of water and 40-150°C in case of oil. Advantages of Bry Air Mould Temperature Controller: Simple & compact design Suitable for all kinds of mould for Injection Moulding Machine Precise temperature control Easy connection for supply & return cooling circuit, by hose nipple

Mold Temperature Controller

75,000 - 95,000 Per NOS

Mold Temperature Controller

95,000 Per piece

1 n (MOQ)

Manufacturer of Auxilaries Equipment

Mould Temp. Controller

Get Price Quote

JD series automatic mould temperature controller is mainly used to bring the mould to a specific operating temperature and hold that temperature constant by heating and/or cooling a Circulating fluid heat transfer medium. This series adopts heat-exchanging principle,using water or high-heat-conduction oil as transfer medium. Unstable temperature in the process of mould forming always tends to produce unqualified products. According to the principle of heat exchange, JD’s mould temperature controls make use of water and high property heat transferring oil as a medium to keep a proper stable temperature in the process of mould forming so as to guarantee high quality of products and raise the productive efficiency. Features: Mould Temperature Controller – Hot medium liquid : Water or oil convertibility, Either water or oil can be used as a hot medium liquid according to the needs of mold forming temperature. Its high selectivity is certain to bring in high economic efficiency. While most of the MTC’s (Mould Temperature Controller) only support one medium, Our MTC (Mould Temperature Controller) supports both Water and Oil Medium. – Vertical Pump: The flow of vertical pump can be always kept steady, making its service life long and durable. – Stainless medium tank: Our Mould Temperature Controller’s interior tank will not get rust for long term, which is sure to prevent from any blockade of pipes and keep long-term service of pump. – Transparent water (oil) level viewer: The transparent water (oil) level viewer can easily be used to view and inspect the quantity of medium liquid and be reminded to refill the medium liquid from time to time. – Automatic alarming device: While water (oil) shortage occurs in the container, this device will automatically light up and start alarming and cut off the electric power of heaters and pumps, thus guaranteeing the machines (MTC) safety as well as the person running it. – High-precision automatic temperature control: The measure of temperature is very sensitive and accurate, little change of temperature helps to keep products both fine and delicate. – Minimize Products Wastage: The mold can reach the required temperature right at the beginning of operation, thus can obviously minimize products shortage. – Maintain proper temperature: Either in continuous operation or in temporary shutting down, mold-forming temperature can always be kept proper to guarantee the best quality of products and further improve the forming process. – Compact in size, light in weight: Easy to install, convenient to operate, convenient to move and little room to occupy, our Mould Temperature Controller (MTC) is perfect choice for any Company running any kind of mould.

Aqua Mould Temperature Controller

Get Price Quote

AQUA CONTROL SYSTEM is pleased to announce our new product of water controller unit "DOLPHIN"_ ACS 15 series and chiller.lt is widely used in plastic industries eg INJECTION MOULDING INDUSTRIES for Mould Temperature controller (MTC),EXTRUSION INDUSTRIES chilled roller Temperature controller and in CHEMICAL INDUSTRIES for chilled water circulation APPLICATION: 1.Water is common denomiator for every living thing on the earth. Water seeps through the soil and rocks and all the while it keeps on collecting a number of largely undesirable elements such as hardness agent, odour & chemical pollutant due to industries, DOLPHIN-ACS 15 will remove hardness from your water by passing through high exchange capacityion exchange base resin media within permissible limit (350 ppm to less than 5 ppm). 2.Numerous industrial processes run by supply and dissipation of heat surplus process heat is here drawn off by cooling with cold water from the customer.High performance water cooled compact chillers of the DOLPHIN-ACS 15 range increase productivity, shorter cycler times and reduce manufacturing cost. The resulting good level of efficiency causes low operatig costs,high reliability of operation and long life 3.In fact chiller have some limitation in temp.exactness.lt can work within 5*C to 10*c temp.different. Now it is necessary to use exact *C tempered water to get best performance in Injection Moulding Industries,Extrusion Industries as well as Chemical Industries while processing.DOLPHIN-ACS 15 take over this important task. In Injection Moulding Industries Mould temp.play an important roll to produce best Moulding.In Extrusion Industries the chilled roller should work within short temp. diffence say +/- 1*C. to get better performance. In this part of DOLPHIN-ACS 15 Water temp. range is 25*C-80*C. Microprocessor controlles developed especially for the application guarantee an exact temp. control. The compact design allows the installation even in case of restricted space.

Automatic Mold Temperature Controller

Get Price Quote

We are offering automatic mold temperature controller.automatic mold temperature controller features hot medium liquid: water or oil convertibly; either water or oil can be used as a hot medium liquid according to the needs of mold forming temperature. Its high selectivity is certain to bring in high economic efficiency. Vertical pump : the flow of vertical pump can be always kept steady and its service life keeps long. Stainless medium tank: this interior tank will not get rust for long term, which is sure to prevent from any blockade of pipes and keep long-term service of pump. Automatic alarming device high-precision automatic temperature control. Minimize products wastage compact in size, light in weight

Mold Temperature Controller

Get Price Quote

The extremely economical GMC Series accurately monitors and maintains temperatures to within 1 degree of set point, and maintains the optimum production temperature by sampling mould temperature four times every second. As a result, target temperatures are hit with precision and are accurately maintained cycle after cycle, maximizing output and minimizing rejects.

Mould Temperature Controller

Get Price Quote

We supply a qualitative range of Mould Temperature Controllers that are manufactured by us using optimum grade raw material. These are specifically designed to maintain invariant temperature of mould during the entire moulding process. Widely demanded in various industries, our range is known for its reliability, accuracy, high performance and long working life. Further, we provide these in different specifications to meet the diverse choices of clients.

Mold Temperature Controller

95,000 - 150,000 Per Piece

1 Piece(s) (MOQ)

The heating barrel is made from the stainless steel and cleaned easily. Air blowing can be selected for the mould to ensure temporarily clean placing and prolong the service life.Controlled by PID micro computer, accurate temperature control. Pump overload protection to ensure service life effectively.The device is equipped with multi-fault indicator to facilitate the customer knowing the reason and solving in time. Alarm device for low liquid level to guarantee system running safety. Switch of main power source conforms to CE safety standard. Alarm device for Phase reverse to guarantee system running safety.

Mould Temperature Controller

100,000 Per

Mould Temperature Controller

Get Price Quote

STC series automatic mould temperature controller is mainly used to bring the mould to a specific operating temperature and hold that temperature constant by heating andor cooling a Circulating fluid heat transfer medium.

Mould Temperature Controller

72,000 Per Piece

Mold Temperature Controller

Get Price Quote

As our Mold Temperature Controllers have gained huge popularity in the global markets, we have become the reliable name involved in its exporting and supplying. Compliant with the set industry standards, our Mold Temperature Controllers are safe to use and highly efficient.

Mold Temperature Controller

Get Price Quote

Mould Temperature Controllers to our clients. These are used to maintain a mold at a constant temperature, and also eliminate stress in the molded components. These controllers are manufactured using quality materials and are tested by our experts before delivery to our clients. The product is known for its reliability, accuracy, high performance and long working life. Additionally, we provide these at reasonable prices in different specifications as per the client's requirements. Oil or water based models available. Tank made out of S.S. & completely insulated. Pump mounted inside a tank , thus eliminating any chance of oil leakage for models upto 180o C Special graphite seals for models upto 300o C Digital Temperature ControllerPID used for Procession accurate Temp control.