Skid Mounted Oxygen Plant

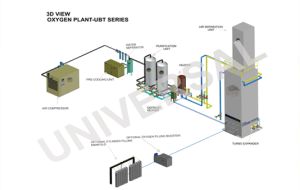

We are leading manufacturer and exporter of Skid Mounted Mobile Oxygen Plant and Nitrogen Plants in India. We have manufactured over 500 Air Separation Plants & Equipments since 1985 in technical collaboration with ING. L & A BOSCHI, ITALY over 30 years. We are manufacturing oxygen plant mobile skid mounted version which you can move one place to another place easily. It is compact and containerized highly efficient and durable oxygen plant. Premium quality materials are used in the making of the compact oxygen plant and machinery. Our high quality portable oxygen production plant is very useful for small and medium scale hospital medical industries.Latest technology of ING. L& A BOSCHI ITALY- Our complete technology, designs and manufacturing skills have been acquired from ING L&A BOSCHI, ITALY and perfected in the last 30 years. Dr. Boschi has certified our plants to meet international specifications and we are certified ISO 9001:2008 Company and selling under the same world are known ‘Boschi’ Italy brand name. Our skid mounted design and technology is world-famous. Our skid mounted plants do not require any foundation for their working and saves you a lot of space. Use of skid mounted technology is economical and effective for small industries. It is especially designed for air force, navy and other similar organizations where movement is important. Main parts of oxygen plants AIR SEPARATION UNIT (COLUMN- COLD BOX) – 100% stainless steel column as per ASME standard. PROCESS PURIFICATION UNIT (SKID MOUNTED) - Compact Boschi Design. AIR COMPRESSOR- Steady Design Oil Free Rotary Air Compressor. LIQUID OXYGEN PUMP- For Filling Oxygen Cylinders At 155/200 bar. OXYGEN CYLINDER FILLING SYSTEM- Oxygen is filled into gas cylinders by the latest system. Main features of skid mounted oxygen plants ZERO maintenance Atlas Copco air compressors. Very low power consumption. (Saving up to 30% power and zero maintenance) Saving of water as air compressor is air cooled. 100% stainless steel construction column as per ASME standards. (No copper or Cheap Aluminium) High purity Oxygen for medical/hospital use. No concrete foundations as all machinery is skid/floor mounted. Uses of oxygen Medical-hospitals Industrial Cutting of thick steel All type of industries

...more

pure nitrogen plants

Pure Nitrogen Plants We are leaders in manufacturing, fabricating and supplying pure nitrogen plants. Our nitrogen machinery is fabricated using the advanced cryogenic distillation technology. We entered into a technical collaboration with ING. L. & A. BOSCHI of Italy to acquire the latest technology and designing expertise. The plant machinery generates nitrogen with purity up to 99.99%, which is excellent for industrial and medical applications. Our nitrogen gas plant machinery comes in different sizes and capacities from 50 m3/hour to 10,000 m3/hour. Our machinery delivers seamless performance for years. For compliance with quality standards, we have been given ISO 9008:2015 and CE. Pure nitrogen plants are supplied to customers located all over the world. Apart from the fully automatic functioning and advanced features, the machines consume low power and perform exceptionally well. Annual maintenance of the machines is also very low. They require minimal area to set up and run. Some salient features of the plants include high performance, sturdy design, advanced components and many more. Features Easy installation and commissioning. Low power consumption due to Low pressure (5 to 7 Bar) process. Low maintenance due to no reciprocating parts. Fully automatic air cooled design Rotary Air Compressor. Nitrogen output at high purity up to 5 PPM. CE certified product with design as per European Gas Association guidelines for ASP’s. Cryogenic expansion of air for cooling via Expansion Turbines. No special civil foundation required for any part of the plant. Hydrocarbon vapor level reduced below 0.003 PPM to ensure safe operation. Scope & Supply of Pure Nitrogen Plants l. Air Compressor : Rotary air compressor screw type can be used for smaller size plants upto 50 m3/hr & 1000 m3/hr. Upto 40000m3/hr. Centrifugal compressor can be used for higher size plants. 2. Air pre cooling system : Air separation plants adopt chilling system in all air pre-Cooling systems. 3. Air purification system : Molecular sieves are used in the air purification system to remove the Co2 & moisture for the process air at low- Pressure. 4. Air separation column : (Air separation column-cold box) consists of outer steel casing, Main heat exchanger, liquefier, Bottom column, Top column, Condensor, Sub-cooler, Liquid oxygen & nitrogen filter. Cooling pipe line, insulation material, Digital electronic temperature indicator & scanner, PT 100 sensor, DP gauge monometer, Expansion valve with long stem type with pointer & index & wheel -1 set. 5. Expander : Expander is used for giving cooling to the air for the liquefaction process and braked by booster, so as to reduce the expanded air volume, stabilize the upper columns working condition and reduce power consumption. The turbine expanders have complete trouble free working and long life and reliability. 6. Control Panel : Pure nitrogen plants can be configured for automatic operation through a pc. This will use a out switching valves of German or Japanese And motorized cryogenic valves on cold box. Applications OIL & GAS BEVERAGE INDUSTRY (COCA COLA ,JUICE BOTTLING ) GLASS INDUSTRY FREEZING SEAFOOD NITROGEN REFINERY TUNNEL FREEZING & MANY OTHERS

...more

PSA Oxygen Generator Plant

We manufacture PSA oxygen plant using the latest PSA (Pressure Swing Adsorption) technology. Being the leading PSA oxygen plant manufacturer, it is our motto to deliver oxygen machinery to our customers that is at par with international standards and yet is very competitively priced. We use premium quality materials bought from the best suppliers in the industry. Oxygen generated in our PSA oxygen generator meets the requirements of industrial as well as medical applications. Numerous companies from around the globe are using our PSA oxygen plant and are generating oxygen on-site for running their operations. Oxygen produced in our high purity oxygen generator meets the standards of US Pharmacopeia, UK Pharmacopeia &Indian Pharmacopeia. Our oxygen generator is also used in hospitals because the installation of oxygen gas generator on-site helps the hospitals to produce their own oxygen and stop their dependency on oxygen cylinders bought from the market. With our oxygen generators, the industries and medical institutions are able to get uninterrupted supply of oxygen. Our company uses cutting-edge technology in the making of the oxygen machinery. Salient features of PSA oxygen generator plant Fully automated- systems are designed to work unattended. PSA plants are compact taking little space, assembly on skids, prefabricated and supplied from factory. Quick start-up time taking only 5 minutes to generate oxygen with desired purity. Reliable for getting continuous and steady supply of oxygen. Durable molecular sieves that last around 10 years. How PSA oxygen generator plant works PSA oxygen generator plant is fabricated using advanced Pressure Swing Adsorption technology. As is well-known, oxygen constitutes around 20-21% of atmospheric air. PSA oxygen generator used Zeolite molecular sieves to separate the oxygen from the air. Oxygen with high purity is delivered whereas the nitrogen absorbed by the molecular sieves is directed back into the air through the exhaust pipe. Pressure swing adsorption (PSA) process is made up two vessels filled with molecular sieves and activated alumina. Compressed air is passed through one vessel at 30 degrees C and oxygen is generated as a product gas. Nitrogen is discharged as an exhaust gas back into atmosphere. When the molecular sieve bed is saturated, the process is switched to the other bed by automatic valves for oxygen generation. It is done while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Two vessels keep working alternately in oxygen production and regeneration allowing oxygen is available to the process. Applications of PSA Plants Our PSA oxygen generator plants are used across numerous industries including: Paper and Pulp industries for Oxy bleaching and delignification Glass industries for furnace enrichment Metallurgical industries for oxygen enrichment of furnaces Chemical industries for oxidation reactions and for incinerators Water and Wastewater treatment Metal gas welding, cutting and brazing Fish farming Glass industry

...more

psa oxygen gas plants

PSA oxygen plants and oxygen generators are our small capacity plants, which are small in size and thus easy to carry from one place to another. The PSA oxygen plants generate oxygen gas, which find application in a number of industries. For being technologically very advanced and high performing, the systems are run for years without maintenance or malfunctioning. The machines are generally purchased by companies and individuals whose requirement is small. If you want to buy the systems, you just need to contact us. We will provide technical information and quotation of the machines. Technical collaboration with an Italian company helps us to upgrade our products time to time.

...more

Psa generator

We are a leading company for manufacturing and supplying oxygen generators, which are technologically very advanced, fully automatic and perform at minimal cost. The oxygen gas generation plant of our company manufactured under the technical assistance of ING. L. & A., BOSCHI, ITALY that performs exceptionally well in the different locations all over the world. The capacity of the systems range from Range 06 m3hr to 40 m3hr and gives guarantee of highly pure output, which is oxygen upto 98 to 99%. The operating Air Pressure of the cylinders is 150 bar (200 - 300bar Optional high capacities).

...more

oxygen plants

Our Oxygen plants are designed and developed by incorporating the state of the art technology in order to make them perform as per the plants of international standard. Our medical oxygen plants are assembled with top quality components under the guidance of technical skilled and experienced manpower. With the technical collaboration and close association of ING. L. & A. BOSCHI of Italy, Universal Industrial Plants Manufacturing Co. (P) Ltd. develops and designs automatic and efficient plants. Our association with Dr. Boschi of Italy has helped immensely to manufacture the plants which are in accordance with the international standards and CE certification. Being a trusted Oxygen plant manufacturer, we are very particular about the quality of our oxygen production equipment.Oxygen and Nitrogen are created from the purest form of liquid air which is separated by rectificationdistillation process.

...more

oxygen nitrogen plants

We are main supplier of this product.

oxygen nitrogen gas plant

We sell high quality products at discounted rates; and manufacture the plants by using high quality raw materials. With high quality products and our good customer service- both before the sale as well as the after sale services, we have been successful in retaining our clients and lure potential ones. Our plants are incorporated with the latest technology ensuring error free working and longevity. Automatic change over of molecular sieve available as option.

...more

Oxygen Generator

Salient features : Production attained within 15 minutes Ready to start Lowest power consumption Compact size Fully automatic operation Digital flow meters Digital purity analyzers Low cost of production Touch screen panel Our oxygen generators are compact and highly reliable, which were initially designed for remote installation, military applications and can also be installed on board of ships, islands and on mobile trailers. They are very suitable for captive users and dealers of oxygen who want to fill oxygen in cylinders without any headache. In order to update technology of our plants, we form a R&D unit responsible for analyzing the international market and update our range accordingly. The department is managed by a team of senior engineers to achieve perfection. Our company manufactures a variety of oxygen generators with diverse capacities that range from 20 m3/hr to 1000 m3/hr. Before booking your dream plant, consult our customer care executives. We have a team of customer care executives who have given proper training to solve the day to day queries of customers. First ascertain your requirement and then apply. To get some idea about production and purity you need, you can contact our customer care executives.

...more

Oxygen Gas Plants

All our products are shipped only after passing through our stringent quality test. We have professionals to pack the devices in an order they do not harm or damage during shipping. To get our quotes, either fill in online query form or call us directly. Our customer care executives entertain each customer with honesty. On the other hand, we are striving to improve our products through continuous research and development. As a reputed and known manufacturer and exporter of oxygen plants, we give guarantee of high quality, efficient and more industry specific devices. All our products are shipped only after passing through our stringent quality test. We have professionals to pack the devices in an order that the goods are unharmed and damage free during shipping.

...more

nitrous oxide plants

We are one of the leading manufacturer and exporter of nitrous oxide plants. Our Nitrous Oxide plant are very safe and economical plants with an efficient Generation system which reduces power consumption and adds on to safety. A storage battery assembly for separation of Nitrogen is another safety feature with the Universal plant. The gas manufactured conforms to Indian Pharmacopeias, US & European standards and is stored in liquid state which can be directly filled into cylinder.

...more

nitrogen plants

nitrogen gas plant

Efficient products are a result of our association with ING. L. & A., BOSCHI of ITALY. In addition to the collaboration, we design and develop products under the supervision and guidance of experienced and skilled engineers. An industry leader in the field of manufacturing gas plants, we guarantee high quality plants at competitive rates.

...more

medical oxygen generator

Universal Boschi is acclaimed for fabricating and manufacturing medical oxygen generators for applications in hospitals and other medical purposes. Our oxygen generator for hospitals is preferred because of our reputation for manufacturing high quality oxygen machinery using the modern advanced cryogenic distillation technology. Being the leading medical oxygen generator manufacturer, we are committed to offer our customers the best medical oxygen generator price while maintaining world-class quality and customer service. We have entered into a technical collaboration with ING. L. & A. Boschi of Itlay, which is an acclaimed company for its cutting-edge cryogenic technology. The proprietary Boschi technology is used in the fabricating of the machinery. Boschi technology provides you with the cross row trays, cryogenic materials and high purity heat exchangers due to which we get regular flow and high purity of liquid oxygen. Situated in New Delhi, our medical oxygen generator factory is reputed for fabricating oxygen production plants with precision and high skills. Our factory is also equipped with R & D center, which is engaged in innovating oxygen generators for hospitals as per the market requirements and trends. We invest a great deal of our resources in research to make medical oxygen generator plant which delivers top-class performance and is durable. Our medical oxygen generator cost is competitive in the market. Our company has emerged as the most popular medical oxygen generator manufacturer in India by dint of its investment in quality improvement, designing and customer service. Our medical oxygen generators come in different capacities and sizes ranging from 20m3/hour to 200m3/hour. QUICK FACTS ABOUT MEDICAL OXYGEN GENERATORS Generate 20 to 200 liter/hour High purity LOX with 99.7 PPM Sold in more than 40 countries Produce LOX directly from atmosphere using cryogenic distillation technology Operates continuously for 24 hours seven days a week APPLICATIONS OF MEDICAL OXYGEN GENERATORS Provide a basis for virtually all modern anaesthetic techniques Restore tissue oxygen tension by improving oxygen availability in a wide range of conditions such as COPD, cyanosis, shock, severe hemorrhage, carbon monoxide poisoning, major trauma, cardiac/respiratory arrest Aid resuscitation Provide life support for artificially ventilated patients Aid cardiovascular stability SALIENT FEATURES OF MEDICAL OXYGEN GENERATORS Air separation column( Cold Box ) is fabricated using A Grade leak-proof stainless steel Skid mounted Easy to operate and maintain Durable Low power consumption PRODUCT DESCRIPTION: Compression of atmospheric air : Air is compressed at a very low pressure of 5-7 bar( Kg/cm2) using latest air compressors pre-cooling. It is the 2nd stage of the process and uses a low pressure refrigerant for pre-cooling the warm processed air incoming from air compressor to temperatures around 5 to 10 degrees Celsius before it reaches the purifier. Purification of air by purifier : Air enters purifier made up of twin molecular sieve driers working alternately. The sieves separate carbon dioxide and other impurities from the process air before it reaches the air separation unit. Cooling of air by expander : Air is cooled below sub zero temperatures for ensuring liquefaction and cryogenic refrigeration. A highly efficient expander is used to cool air below -165 to -170 Celsius. Separation of liquid air into oxygen and nitrogen : After air is cleaned of impurities, it enters the fin type heat exchanger where the air is cooled below sub zero temperatures by air expansion process in the expander. Air becomes liquefied when it enters air separation column and gets separated into oxygen and nitrogen by rectification. Oxygen generated in this way has purity up to 99.7% Oxygen filling cylinders : Oxygen is filled into oxygen cylinders for distribution or storage as per the requirements of the customers. Hospitals use medical oxygen cylinders for keeping oxygen handy for emergency use.

...more

liquid storage tank

Liquid storage tank is made up of a double walled cylindrical tank. The space between inner and outer vessel consists of insulating material to safeguard it from the surrounding heat. The space is evacuated to a high vacuum in order to ensure minimum evaporation. The cold convertor used in the cryogenic storage tank is equipped with pressure building arrangement with automatic pressure build-up regulator. Designing of the liquid oxygen storage tank is done in way to ensure that it is sturdy, compact and easy to operate. Top end liquid filling decreases the pressure inside the tank and the bottom filling increases the pressure. The pressurizing system is used for increasing the pressure when the liquid oxygen is uploaded to tanks or gas line vaporizers. As the pressurizing system is used for regulating the opening of both top and bottom filling valve, there is almost no change of pressure during liquid delivery. It enables constant liquid supply to vaporizer. Liquid nitrogen storage tank can store liquid oxygen at temperatures up to (-196°C) with capacity ranging from 200 liters to 1, 50,000 liters with option of low and high pressure. Cold convertors are used for supplying pressure pipe line networks after gasification in atmospheric heat exchangers, storage tank networks or tanks of smaller capacity for low liquid temperature directly. Salient Features Simple tube structure No need to replace the insulation material regularly Excellent insulation and low static evaporation Tank inter layer passes strict leakage test by helium gas spectrometer with a leak rate of less than 1 x 10 ?¹º pa-l/s Convenient system operation and small area requirement The tanks can supply cryogenic liquid from the bottom by connecting it to an outer vaporizer and cryogenic pump. We can supply the whole system along with the valve system and piping based on the customer requirement Low area requirement, safety Simple operating convenience Vacuum powder insulation cryogenic tanks are used to supply liquefied oxygen, nitrogen, argon and other liquefied gases. Applications of Liquid Oxygen Storage Tanks Chemical Machinery Medical Treatment Electronics Mining Metallurgy Fisheries Pharmaceutical

...more

liquid oxygen pump

We have a customer care center filled in with technically qualified professionals to guide our existing as well as potential customers. The Centre remains operational round the clock in order to serve the people of different geographical regions. Anyone can contact us any time. A customer can send us an email or call us directly. We would reply without delaying. We would also be providing technical details and quotation of a machine after confirming a particular model.

...more

liquid oxygen plants

Small capacity liquid oxygen plant a type range – 20 litres/hr to 60 litres/hr (with liquid production lox and lin) (for 100% liquid production for filling liquid tanks or 50% gas & 50% liquid) for production of liquid oxygen /nitrogen for filling in tanks with leakproof stainless steel column and skid mounted version for high purity medical and industrial oxygen.basic principle our oxygen plants taps oxygen and nitrogen from the atmosphere air. The feed air is entered into the molecular sieve purification system to separate the moisture and co2 from the process air. Subsequently, it is liquefied by cryogenic cooling using the latest plate and fin, high efficiency heat exchangers and expanders. The liquid air gets separated into oxygen and inert gases in the air separation column. Liquid oxygen is stored in a liquid storage tank. special features of liquid oxygen plants plants use "oil free" rotary screw /centrifugal oil compressor working between 0.6 to 1.0 mpa. use aluminum brazed exchangers and packed columns for high efficiency. turbo expanders (oil or air bearing) for trouble free operation. plants above "500" are supplied with automatic plc control. we provide qualified engineers for supervision, installation and start up of all our plants as well as training of manpower at customers site. very low power consumption with proven performance and zero maintenance required for the machines. 100% reliability for oxygen gas quality for industrial & hospital use. liquid purity is high for medical and industrial application. process description : air compressor : air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa). It is done by using the latest compressors (screw/centrifugal type). pre cooling system : the second stage of the process involves use of a refrigerant for pre-cooling the processed air to temperature around 12 deg c before it enters the purifier. purification of air by purifier : the air enters a purifier, which is made up of twin molecular sieve driers that function alternatively. The molecular sieve separates the carbon dioxide & moisture from the process air before the air reaches at air separation unit. cryogenic cooling of air by expander : the air must be cooled to sub zero temperatures for liquefaction. The cryogenic refrigeration and cooling is provided by a highly efficient turbo expander, which cools the air to temperature below -165 to-170 deg c. separation of liquid air into oxygen and nitrogen by air separation column : the air that enters the low pressure plate fin type heat exchanger is moisture free, oil free and carbon dioxide free. It is cooled inside the heat exchanger below sub zero temperatures by air expansion process in the expander. It is expected that we achieve a difference delta as low as 2 degree celsius at the warm end of exchangers. Air gets liquefied when it reaches at the air separation column and is separated into oxygen and nitrogen by the process of rectification. liquid oxygen is stored in a liquid storage tank : liquid oxygen is filled in a liquid storage tank that is connected to the liquefier forming an automatic system. A hose pipe is used for taking out liquid oxygen from the tank.

...more

Liquid Oxygen Plant

Universal Boschi in technical collaboration with ING. L. & A. Boschi of Italy manufactures and exports liquid oxygen plant that performs at low pressure leading to low power consumption, low upkeep expenses and high yield. Our company appreciates worldwide for manufacturing technologically advanced plants. In fact, a single plant can offer both oxygen as well as nitrogen. The liquid oxygen plant offers oxygen with purity upto 99.7% and nitrogen with purity upto 99.99%.

...more

Liquid Oxygen-Nitrogen Plant

Universal Boschi in technical collaboration with ING. L. & A. Boschi of Italy manufactures and exports liquid oxygen-nitrogen plants, which perform as per the plants of international market. Apart from technology, we also incorporate design and drawing of Dr. Boschi in our products in order to make them reliable, durable and high performing. Our oxygen plants are being manufactured as per the latest technology & design of Dr. Boschi of Italy. Its technology has been proven all over the world for working efficiency, optimum performance & trouble free operation. Salient features of liquid oxygen-nitrogen plants Oxygen and nitrogen is made from atmospheric air The process of manufacture engages deep refrigeration/cooling of atmospheric air involving cryogenic temperatures It is made from the purest form that is liquid air which is separated by process of rectification/distillation It can be drawn in liquid form or converted into gas up to 155/200 bar by a built in liquid oxygen/nitrogen pump Oxygen purity upto 99.7% and nitrogen purity is upto 99.99% or ppm grade can be produced There is no requirement of especial civil foundation, raw materials and no recurring cost of Chemicals in the BOSCHI process The plants are designed for continuous duty and are automatic and can be operated just by one person We aim at manufacturing high quality plants that help our customers to become more profitable, reliable and, obviously, environment friendly. Believing customers satisfaction is our satisfaction entice us not only use latest raw materials and equipment, but also the best engineers available in the market to fabricate fully automatic and high performing plants. To take out the burden of our customers, we also offer commissioning, installation, erection and after sales services by the hands of expert engineers. In order to better serve our customers, we form a department – namely customer care department. Filled in with a number of customer care executives, the department, obviously with proper training, solves day to day queries of our customers spread out worldwide. Anyone can contact us now either by writing an email or calling directly and get queries solved.

...more

Liquid Oxygen Nitrogen Plant

Universal Boschi in technical collaboration with ING. L. & A. Boschi of Italy manufactures and exports liquid oxygen plant that performs at low pressure leading to low power consumption, low upkeep expenses and high yield. Our company appreciates worldwide for manufacturing technologically advanced plants. In fact, a single plant can offer both oxygen as well as nitrogen. The liquid oxygen plant offers oxygen with purity upto 99.7% and nitrogen with purity upto 99.99%.

...more

liquid nitrogen plants

We are leading manufacturers and suppliers of liquid nitrogen plants that are impeccably designed in technical collaboration with ING. L. & A. Boschi, Italy. Our liquid nitrogen generators are fabricated using proprietary technology of BOSCHI Italy who have developed and specialize in small, medium & large capacity, high purity Liquid Nitrogen plants .The special advantages are the cross flow trays, cryogenic material of construction and high efficiency heat exchangers due to which we are able to achieve steady flow and high purity production of Liquid Nitrogen. We specialize in making these liquid Nitrogen plants of superior designing and cutting-edge cryogenic technology to achieve purity from 99.9% up to 99.999%, OR part per Million (PPM) as per the application and requirement of the end user. We are offering a wide range of capacities from 10 Liters/Hour to 3000 Liters/Hour Liquid Nitrogen plants. Quick Facts about Universal BOSCHI Liquid Nitrogen Plants Produce from 10 to 3000 liters/Hour High purity LIN from 99% to 99.9999% upto PPM levels In operation all over the world more then 40 countries Produce liquid nitrogen directly from the air using advanced cryogenic technology Operate 24 hours a day, seven days a week reliably, continuously and safely APPLICATIONS OF LIQUID NITROGEN Oil & Gas Beverage & food industry Freezing Seafood & other items Tunnel freezing In the veterinary industry for the cryopreservation of blood cells like (sperm and egg) Glass industry Used for food preparation and making ultra-smooth ice cream Many others IMPORTANT FEATURES OF LIQUID NITROGEN PLANT Air separation column (Cold Box) is manufactured using A Grade leak-proof stainless steel. It is offered with a Skid Mounted version. It is quick to start and easy to maintain. Hassle-free operation for long time Spare parts easily available Consumes very low power PRODUCT DESCRIPTION: Compression of atmospheric air : Air is compressed at a very low pressure of 5-7 bar (kg/cm2) using latest Air compressors (screw/centrifugal type). Pre cooling system: It is the 2nd stage of the process and uses a low pressure refrigerant for pre cooling the warm processed air incoming from air compressor to temperatures around 5 to 10deg c before it reaches the purifier. Purification of air by purifier : Air enters a purifier made up of twin molecular sieve driers, functioning alternatively. The sieves separate the carbon dioxide and moisture from the process air before it enters the air separation unit. Cooling of air by expander : Air is cooled below the sub zero temperatures for achieving liquefaction and cryogenic refrigeration. A highly efficient expander is employed to cool air below -165 to -170 temperatures. Separation of liquid air into oxygen and nitrogen by air separation column : Air having been cleaned of hydrocarbons, dust, moisture and carbon dioxide enters into super efficient fin type heat exchanger where the air is cooled below sub zero temperatures by air expansion process in the expander. It becomes liquefied when it enters the air separation column & gets separated into oxygen & nitrogen by the process of rectification. Nitrogen so generated has purity up to 99.9% to 99.9999% as per the requirement of the end user. Liquid nitrogen is filled in liquid storage tank : Liquid nitrogen is stored in a vacuum insulated cryogenic storage tank which is connected to the outlet in the air separation column via insulates/vacuum pipe forming a independent unit where no operator attention is needed.

...more

liquid nitrogen plant

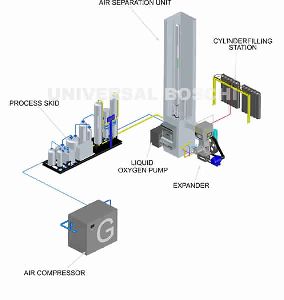

step 1 : Air is sucked by a multi stage air compressor and passed via the following stages. step 2 : COMPRESSION OF AIR This is accomplished by the multistage highly effective air compressor. step 3 : PURIFICATION OF AIR This is performed by the Process Skid. step 4 : COOLING & LIQUIFICATION OF AIR It is carried out by a latest expansion engine and also by a refrigeration unit (for 100% liquid output). step 5 : AIR SEPARATION (RECTIFICATION) It is carried out by the special AIR SEPARATION UNIT comprising of upper column, lower column and special exchangers. The separation of air is performed by the CRYOGENIC PROCESS. The final product from a liquid OxygenNitrogen goes to the storage tank.

...more

Liquid Nitrogen Generator

High Purity Of Nitrogen >99.5%.(99.999% Optional)Suitable For Coca Cola Juice BeverageElectronicsFoodand Industrial Uses. Liquid Nitrogen Pump(Optional) Can Be Added For Direct Compression Of Nitrogen In Cylinders. Heavy Duty Compressor For 24 Hour Operation. Very Long Life And High Quality Oxygen As

...more

Liquid Gas Plants

Our company appreciates worldwide for manufacturing technologically advanced plants. In fact, a single plant can offer both oxygen as well as nitrogen. The liquid oxygen plant offers oxygen with purity upto 99.7% and nitrogen with purity upto 99.99%.

...moreBe first to Rate

Rate ThisOpening Hours