Toilet Cleaner Tough stain removal

Get Price Quote

Oil Blend Black Floor Cleaner

Get Price Quote

100 Pack (MOQ)

Best Deals from Oil Cleaning System

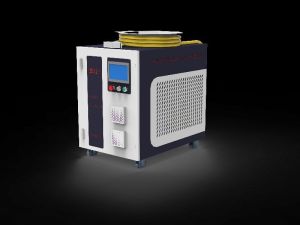

laser cleaning machine

850,000 Per piece

1 Unit (MOQ)

This is hand held Laser Cleaning Machine, available in 1 and 2 kw laser power, being used to remove rust, oil, grease, etc from metal surfaces, to prepare the matals or parts for paint or powder caoting, etc.

Hand Held Fiber Laser Cleaning Machine

Get Price Quote

1 Piece (MOQ)

Oil & Grease Hand Cleaner

Get Price Quote

We assure purchasers that our entire range is subjected to stringent quality policies to meet industry standards. Keeping in compliance with the international standards, we ensure that the raw materials used for varied products are 100% certified and quality approved. This helps us in maintaining a set standard of our products. Features Finest composition Aromatic Safe for skin

laser cleaning machine

Get Price Quote

1 piece (MOQ)

Fiber Laser Cleaning Machine

Get Price Quote

1 Piece (MOQ)

Degreasing Tank

Get Price Quote

1 Piece (MOQ)

Made from one piece molded plastic material completely provided with one piece rubber sheet cover. Drain cock and suitable M.S. Iron stand duly painted and ready for use.Screens have to be cleaned for oil stains due to grease and dirty handling. Stain removal process is a simple process using degreasing chemical left in the degreasing tank with the aid of supporting devices for proper handling.Degreasing screens is a very important part of the screen preparation process. It is important to degrease your screens prior to applying emulsion or film because new screens or restretched screens need to be free of grease, oil and dirt to avoid problems with the stencil quality.

Greasy Stain Cleaner

96 Per 500ml

1 Carton (MOQ)

Product Description SAYA's Greasy Stain Kitchen Cleaner, in a 500ml spray bottle, is your go-to solution for tough grease and stains on all kitchen surfaces. Specifically designed for chimneys, stoves, and more, it effectively Helps in removing oily residues without the risk of flammability. This non-flammable formula helps in safety while providing powerful degreasing action. Ideal for daily kitchen cleaning, it effortlessly tackles stubborn grease buildup, leaving surfaces pristine. The convenient spray bottle allows for easy and precise application, helping in thorough cleaning with each use. Upgrade your kitchen cleaning routine with SAYA's Greasy Stain Kitchen Cleaner for a sparkling, grease-free kitchen every time. About This Item: Versatile Applications: From grills and ovens to gas stoves and exhaust fans, our multipurpose cleaner removes grease, grime, and oil residue with ease. It's also perfect for fryers, griddles, dosa, crayon marks, adhesive marks, Inks mark, tawa, and all carbon, oil, and grease deposit areas. Superior Grease-Cutting Formula: Our kitchen cleaner spray is your ultimate solution for tackling the toughest grease and grime. With its concentrated formula, it sets the industry standard for performance, making it perfect for both commercial and domestic kitchens. Effortless Cleaning: Experience fast-action cleaning with our chimney cleaner spray. Its quick-drying formula ensures rapid results without leaving any mineral deposits behind, saving you time and effort. Easy-to-Follow Directions: Simply spray the cleaner on the targeted area, wait a few minutes, and wipe away for sparkling results. For chimney cleaning, remove the filter, apply the spray, and rinse for a clean and fresh kitchen environment. Safe and Non-Toxic: Our non-flammable and chlorine-free degreaser spray is specially formulated for kitchen use, making it safe for both you and the environment. It's suitable for various surfaces including metals, plastic, fiberglass, marble, granite, and glass.

A Plus Tough Stain Removal Toilet Cleaner

35 - 70 Per

1 Ton (MOQ)

Tapklin Tap & Hard Water Stain Cleaner

Get Price Quote

Oil Sump Cleaner

175,000 - 285,000 Per piece

1 Piece (MOQ)

Industrial Vacuum suction unit for Oil and Chips recovery: Cleantek design and manufacturing portable type oil sump cleaner and chips recovery system for engineering industries used in CNC machining shops.This oil sump cleaner removes the dust,coolant,sludge, dirt and chips from the oil sump, filters the dust,sludge and chips from the coolant and returns the filtered pure coolant to the oilsump. High vacuum motor produce vacuum inside the big tank, so that all metal debris,dust, cutting oil is sucked threw the nozzle.CNC cutting fluids contain a host of chemical additives such as biocides, emulsifiers, corrosion inhibitors, anti-foaming agents and more. It can cause skin irritation, rashes and dermatitis. Then it is filtered via multistage filtration before entering into the tank. Afterthat pure coolant collected inside the tank and it is pumped out to the CNC sump. The oil sump cleaner removes the dust,coolant,sludge, dirt and chips from the oil sump, filters the dust,sludge and chips from the coolant and returns the filtered pure coolant to the oilsump. Coolant filter separate the debris, greases and other unwanted contaminate from the coolant. Coolant pumping motor returns the pure coolant to the sump. Sump cleaner keeps the machines clean and free of bacteria and fungus.Therefore Oil Sump Cleaner need to clean this oil, sludge etc.. Features: Direct Drive Turbine Motor for Maintenance Free and continous running operation 100-1000 Litres collection Tank Easy to move & Portable version Easy to Operate High suction power Advantages: Save Stand by Time of Machine Tools Easy to suck the oil and chips and metal parts from machining centres Both SUction and dleivery by simaltaneously Need single operator to use the machine. Save Labour cost Increase the life of the coolant / cutting oil Extended oil change period Improve employee morale Reduced downtime of machine Improve healthier environment in shop floors Cut your cost of dirty coolant disposal by 50% to 90% Better control of coolant concentration ratio Improve machine tool cleanliness Reduce misting Eliminate environmental risks Improve cutting tool life and product quality Minimize coolant pump maintenance activities Safety for worker health

Degreasing Tanks

Get Price Quote

The company is a proficient Manufacturer and Supplier of Degreasing Tanks from Maharashtra. The Degreasing Tanks we make available are manufactured using Butt Fusion Welding Machine 4m span, which is only machine of its kind in India and the latest technology available in the world for plastic fabrication. Degreasing Tanks offered by us are mainly used in various electroplating plants, pickling lines for galvanizing plants, etc. Details : Sturdy MS Structural support lined with FRP can be provided for larger tanks Provisions for inlet, drain, overflow, V-blocks, heaters, Temperature controller, air agitation, cathode movement, dosing, sampling, slant bottom for sludge collection, etc can be provided as per requirement Covering hoods for long tanks can be provided Fumes Extraction and Scrubbing system including Fume Hoods, scrubber system, impellor, ducting and chimney can also be provided Rigorous Quality checks are employed before dispatch on all products. Distinguishing Features : Manufactured using our state-of-the-art equipments like German Wegener Butt Fusion welding machine 4m span, one of its kind in India International DVS Standards compliant Products Excellent team of personnel from best colleges at our disposal - from IIT Bombay, IIM Ahmedabad, Jamnalal Bajaj, etc. Extremely Long Life - more than 10 years Corrosion resistance & Chemical Resistance 100% Leak-proof Zero Maintenance High Tensile Strength, Light weight, Sturdy & Excellent finished

Star Laser Rust Cleaning Machine

2,500,000 Per Piece

1 Piece (MOQ)

Auto Parts Degreasing Machine

Get Price Quote

Fully constructed from stainless steel, double skinned and insulated, the Cleanmake Products L.L.C-multi stage front loading phosphate wash systems are compatible for use with all modern phosphate formulations with multiple process stages to include degreasing/phosphating and multiple rinse cycles (heated and re-circulated or sacrificial to drain). Ideal for batch processing, these units are operator friendly with easy to use control systems to set independent fluid tank temperatures and cycle times.The component basket is rolled from the wash machine onto an external fixed, or mobile, platform for ease when loading and unloading the component parts. Rotating spray bars, with spray jets to suit the application, are positioned above and below the component basket resistant electric immersion heaters and stainless steel wash pump are fitted as standard.Standard Process Stages : Heated degrease/ phosphate wash stage (re-circulated), Primary mains water rinse stage (sacrificial) Heated mains or DI water final rinse stage with passivation (re-circulated). Standard Features : 100% Stainless Steel Construction with 35mm Thick Thermal & Sound Insulation Heavy Duty Stainless Steel Component Basket – Standard Range 1500 x 1000 up to 5000 x 1000 Bespoke Component Holding Jigs also available Air Powered Vertical Opening Door Fully Independent Fluid Tanks Low Fluid Level Protection Door Pressure Sensitive Safety Pad Digital Display Fluid Temperature Control Integral Fluid Filtration Network Electric, Gas or Steam Fired Fluid Heating External Fixed Load/Unload Platform or Wheel Mounted Trolley Pressed Stainless Steel Wash Pump Auto Fresh Water Refill Micro Processor or PLC Controlled Optional Extras : Hot Wash, Rinse, Air Knife & Dry cycles to suit application Disc Type Oil Skimmer Fine Inline Fluid Particle Filtration Oil/Water Separator Units (Insoluble Oils) Steam Extraction Fan & Steam Condenser Units Auto Fresh Water Refill Operators Hand Held Spray Lance 7 Day/24 Hour Fluid Heater Timer Effluent Disposal Pump Auto Detergent Dosing Units (syphon or probe type) DI water plant Integral hot air drying stages Additional chemical/detergent process stages Standalone drying ovens Additional wheel mounted trolleys Typical Applications : Metal Pre Treatment Used prior to powder coating or painting

Laser Rust Cleaning Machine

150,000 Per Piece

1 Piece (MOQ)

Biotique Bio Almond Oil Soothing Face & Eye Makeup Cleanser

Get Price Quote

1000 Piece(s) (MOQ)

Oil Cleaning System

Get Price Quote

Due to the Wire Drawing Process generates very high amount of metal sludge, leads to following problems: Increased Viscosity of Oil and hence Reduced Die Life. Choking of oil Passages. Poor Surface Finish of Wire. Increased Power Consumption. Increased Oil Temperature. High Viscosity Oil Sticks to the Wire being drawn, Increasing Oil Losses. Reduced Oil Life (Requiring Frequent Replacement). Increased Wear & Tear of Pumps.

Centrifugal Clear Cleaner

35,000 Per Piece

Centrifugal Clear Cleaner MOC : S.S 304 S.S 316 High Density Low Density Capacity : 300 LPM to 2000 LPM

Oilmax Centrifugal Oil Cleaning System

Get Price Quote

During quenching, the oil becomes contaminated with scales, soot & degradation products, which interfere with the performance of the oil and may result in unsatisfactory, surface appearance or lower physical properties, such as hardness, than specified. Removal of these contaminants by filtration or centrifuging is necessary to restore the oil to a satisfactory condition for trouble free quenching and good product quality. We supply Oilmax Centrifugal Oil Cleaning System all over the country. Sludge : One of the greatest problems with quench oils is sludge formation. The presence of sludge may cause non-uniform heat transfer, increased thermal gradients and increased cracking and distortion. Sludge may also plug filters and foul heat-exchanger surfaces. The loss of heat-exchanger efficiency can cause overheating excessive foaming and fires. Advantages of Centrifuge : Soot particles up to sub - micron level are removed from quenching oil. This results in better confirmation of cooling rate with TTD diagrams. Oxidation of oil is substantially reduced; hence frequent top-ups are not required. In absence of soot, dis-colorization of work piece is eliminated. Sludge is caused by Quench Oil Thermal and Oxidative Degradation. Applications : Quenching oilFurnace oilWire drawing oilGear oilThermic fluidsEngine oilRust preventive oil and Stamping oil.

Degreasing Tank

Get Price Quote

We offer degreasing tank. With thorough understanding of the relevant industry, we are offering a wide range of degreasing tank. This tank is mainly used for degreasing and is manufactured using best quality raw material and advanced technology. In tune with different needs of our copious clients, we customize the entire range in different sizes and shapes. Our offered range has gained exceptional value amongst our clients for its defined features. Features: precisely designed easy installation dimensional accuracy

Pine Oil Cleaner

Get Price Quote

In order to deliver flawless range of products, we keep stern check on the product development, storage, packaging and delivery. Our up-to-date logistic facilities support us in meeting the delivery deadlines promised to the customers. Details Approx Price - Rs 95 / Litre Minimum Order Quantity - 50 Litre

Oil Cleaning System

Get Price Quote

Electrostatic Oil Cleaners are used for super cleaning of oil to NAS 1638 grade level. Efficiency of this machine to super clean the oil will be in the range of NAS 6-7. These machines are available with or without dehydration attachment. They work on high voltage laminar flow principle, catchhold magneticnon-magnetic ferrousnon-ferrous material. How it Works Electrostatic oil cleaner systems use electrostatic precipitation to remove sub-micron particle of insoluble material, without affecting soluble oil additives. Tiny particles are electrostatically driven to and captured on positively or negatively charged walls of electrodes. Large particles are trapped in the resin impregnated cellulose filter. Coalescing filter in dehydration cell is used for removal of moisturewater up to 5000 PPM. Modern additives-treated oil is highly resistant to deterioration; it can continue service indefinitely if kept clean and contamination free.

Vapour Degreaser

Get Price Quote

Solvent remains still an effective media to remove toughest oil, grease & sticky substance. Designed with High Free Board Zone & very effective condensation system ensures minimal vapour escape to environment. OSHA safety precautions & design yardsticks implemented in every design. Fumes exhaust with recycling also offered. Most economic custom made designs.

centrifugal oil cleaner

275,000 Per

ALMOND OIL SOOTHING FACE and EYE MAKEUP CLEANSER

Get Price Quote

This soothing cleanser is blended with nourishing almond, safflower, sesame, neem and staff tree oils to dissolve heavy face and eye makeup easily and gently. Leaves skin silky-fresh. How to use Bio Almond Oil Soothing Face & Eye Makeup Cleanser : Apply to damp cotton pads or washcloth and gently wipe over entire face and eye area, morning and evening. Ingredients of Bio Almond Oil Soothing Face & Eye Makeup Cleanser: Kusumbhi (Carthamus tinctorius) Arandi (Ricinus communis) Neem (Melia azadirachta) Soya (Anethum sowa) Badam (Prunus amygdalus) Surajmukhi (Helianthus annuus) Malakanguni (Celastrus paniculata) Til Tail (Sesame indicum)

Heavy Duty Cleaner for Cement Based Stain

Get Price Quote

Dubond’s Tile and stone polish is a high quality, water-based, metal cross-linked tile polish for internal use onfloors. The polish enriches the appearance of floor finishes by leaving a hard wearing, matt, satin finish,protecting tiles from the formation of stubborn dirt and stain and has good resistance to normal detergents, typical household spillages and general floor cleaners. Ideal for protecting unpolished natural stone, polished granite and dressed terracotta floors reen Building Rating-Mineral > 30%, Low Emission, Low Emission,Low Ecological Impact, Health Care, Water Based Ideal for usage over unpolished natural stone,polished granite and dressed terracotta floorsFeatures & Benefits-HighQuality Water based Metal cross linked product Protects tiles from the formation of stubborn dirt and stain Good resistance to normal detergents,typical household spillages and general floor cleaners Shelf Life & Storage12-24 months in original sealed packing kept in cool and dry place. store in a dry place in the original container.Health & Saftey PrecautionsKeep out of reach of children. wear suitable protective clothing, gloves, and eye / face protection. after contact with skin wash immediately with plenty of clean water. in case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice.

Stain Remover Floor Cleaner

Get Price Quote

Eight Roller Top Degreasing Machine

Get Price Quote

Well designed for efficient cleaning of eight top rollers (Sixteen Shell) of Ring Frame and Speed frame at a time with roller rotating system by conveyor belts. Auto timer is provided for setting required time for cleaning and pneumatic air connection for roller drying having high productivity with less maintenance. The flushing oil is filtered before it reaches to the oil tank and same oil is recycled again. Fully enclosed electrically operated 1.5 HP, 3 Phase with exhaust fan to remove the fumes from chamber.

centrifugal oil cleaner

Get Price Quote

Centrifugal oil cleaner Top driver pulley is magnetically charged and is designed such that to eliminate any belt slippage and wear as well maximum oil travel and removal from one side of the belt.