Fin Tube Heat Exchanger

10,000 Per Piece

1 Piece (MOQ)

Shell and Tube Heat Exchanger

55,000 Per Piece

Best Deals from Tube Heat Exchangers

Shell & Tube Heat Exchanger

100,000 Per Piece

1 Piece (MOQ)

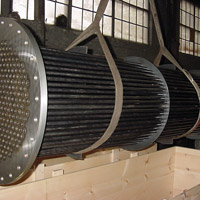

U Tube Bundle Heat Exchanger

Get Price Quote

1 Piece (MOQ)

We are a well-known Manufacturer, Exporter & Supplier of U Tube Bundle Heat Exchanger. Inter Fitment being a crucial point, we manufacture U Tube Bundle Heat Exchanger either as per the specifications laid by the customers or we send our engineers to take the actual dimension of the existing Tube Bundle and the Shell. For the making of U Tube Bundle Heat Exchanger, we have a set of fixtures for 3/2" & 1" OD Tubes. The minimum Bending Radius carried out by us so far is 1.5D. U Tubes manufactured by us meet the TEMA Acceptance Norms of 16 % thinning & 10 % Ovality. The U Tube Bundle Heat Exchanger is generally used for Inter-Coolers, Re-Boilers, Oil Coolers, Strippers, etc. Note : If Client gives us the Existing/Dummy Shell for the testing purpose then Existing/Dummy Shell is used or else Dummy Shell is fabricated for the same and supplied along with Tube Bundle after carrying out the testing.

Shell & Tube Heat Exchanger

150,000 Per unit

1 unit (MOQ)

The Shell & Tube Heat Exchangers are available in various combinations of Glass/Metal, Metal/FRP in Shell & Headers. Shell & Tube heat exchanger consists of a cylindrical shell which houses a glass tube bundle. Tubes are sealed with shell with the help of PTFE tube sheets. Each tube is individually sealedwith tube sheets at both the ends. Baffles are provided in the shell to maintain state of turbulence of fluid as well as to hold the tubes.Shell & Tube heat exchanger can be operated within a temperature range of -40° C to 150° C on either side. However, differential temperature should not exceed 120° C at any point. Also, these can be used predominantly under full vacuum, provided differential pressure does not exceed 3 Bar.The range of overall heat transfer co - efficient in the shell & tube heat exchanger in most of the application range between 300 - 900 kcal/m², h,°C .These are available in different standard models from 3M² to 26M².Glass Shell & tube heat exchangers can be used for condensation, vaporization, cooling and heating. They have come out to be more advanced and beneficial for its following advantages :- Higher Heat Transfer area in one unit Less pressure drop. Stuffing box sealing allows easy tube replacement

Shell and Tube Heat Exchanger

90,000 Per Piece

1 Piece (MOQ)

Shell and Tube Heat Exchanger

95,000 - 550,000 Per Piece

1 Piece (MOQ)

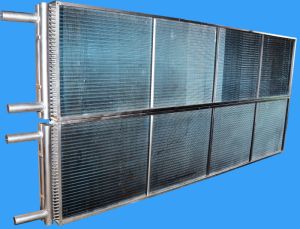

Fin Tube Heat Exchangers

Get Price Quote

25 piece (MOQ)

We present an exclusive range of Finned Tube Heat Exchangers to our clients. These are fabricated using best grade raw materials and advanced technology, which ensures less time and power consumption while functioning. Our offered ranges of these exchanges are appreciated for superior quality and high performance. Clients can avail these from us at reasonable prices. Some of its features are: � High durability � Low maintenance cost � Trouble free operation Applications of finned tube heat exchangers: � Steam air heater / steam radiator � Thermic fluid air heater / thermic fluid radiator � Hot water air heater / hot water radiator � Air heater for fluid bed dryers � Air heater for spray dryers � Air heater for flash dryers � Air heater for dryers

Commercial Tube Heat Exchanger

300,000 - 500,000 Per Piece

1 Piece (MOQ)

U Tube Heat Exchanger

250,000 Per Piece

1 Piece (MOQ)

Shell and Tube Heat Exchanger

200,000 Per Piece

1 Piece(s) (MOQ)

charam techno chemical & equipments (p) ltd. Is listed among the prominent heat exchanger manufacturers in india. The world class shell & tube heat exchanger manufactured by us, can be used for con. Sulphuric acid cooling in the chlorine gas compression system. The heat exchanger is designed according to tema class b & c standard to meet the customer requirements. Our product is tested hydraulically & pneumatically as per standards for the strong structure with special emphasis on the welding quality. The materials used are carbon steel, ss 304, ss 316 & titanium.

Mild Steel Industrial Shell & Tube Heat Exchanger

5,050 Per Unit

1 Unit (MOQ)

Shell & Tube Heat Exchanger

Get Price Quote

1 Piece (MOQ)

Our shell and tube heat exchanger is a type of heat transfer equipment used for transferring heat between two fluids that are at different temperatures. The exchanger consists of a shell that houses a bundle of tubes, through which one of the fluids flows, & the other fluid flows through the shell around the tubes. Shell and tube heat exchangers are commonly used in a variety of applications, such as in power plants, chemical plants, and HVAC systems, to transfer heat between fluids.

Shell and Tube Heat Exchanger

Get Price Quote

1 Piece (MOQ)

Shell & tube type heat exchanger

Get Price Quote

1 Piece (MOQ)

Tube Heat Exchanger

12,000 Per Piece

1 Piece (MOQ)

Finned Tube Heat Exchanger

10,000 - 300,000 Per Piece

1 Piece (MOQ)

Shell & Tube Heat Exchanger

100,000 Per Piece

1 Piece (MOQ)

Tube Heat Exchanger

265 Per Kilogram

1 Kilogram (MOQ)

Courtesy a wide distribution network, our company is capable of catering to buyers IN Bhiwadi(India) and/or anywhere. We are one of the respected names engaged in the process of supplying quality Tube Heat Exchanger at nominal rates. The offered Tube Heat Exchanger is available in various diameters ranging from 5mm to 250mm.

Shell & Tube Heat Exchangers

8,000 - 1,000,000 Per Piece

1 Piece (MOQ)

In most of the Engineering Applications, a medium (air/gas, oil/fluid) needs to be heated or cooled. This requirement is economically accomplished by a Shell and Tube Heat Exchanger. We are prominent Shell & Tube Heat Exchangers Manufacturers, Exporters and Suppliers that are widely used in petroleum refineries, fossil-fuel and nuclear power plants, gas turbines, heating and air conditioning, plastic processing, die casting machines, hydraulic power packs, refrigeration, chemical industry, textile mills, evaporation and drying system, food and dairy industry. Selection of material depends on the purpose for which the Shell & Tube Heat Exchanger has to be installed. Why Our Shell & Tube Heat Exchangers? Leakage Testing / Pressure testing are repeated to assure no wastage occurs High dimensional accuracy Robust construction High performance Durable