Warper Machine

20 Per Piece

1 HP Steam Ironing Machine

30,500 Per piece

Best Deals from Textile Machine

textile dropper

Get Price Quote

We manufacturer and supply a vast array of Weaving Accessories. Our range includes Dropper, Reeds and Heddles.Easy availability of drop wires for mechanical and electrical warp stop motion as per We offer Droppers that are manufactured using quality hardened and tempered spring steel strip and STAR BRAND(stainless steel), ensuring greater durability. These are provided with electro plating which helps to protect against rust. In addition, our Droppers are available in the following finishes: Nickel plated finish Electroless nickel plated Zinc plated finish Golden yellow zinc plated finish Stainless Steel The carefully rounded edges and highly polished thread eye ensure faultless, undisturbed weaving of fine and low twist warp yarns. Textile Dropper with 16.0mm & 1.0 mm thickness are also manufactured on request Special type of Dropper will be manufactured with acceptable order quantity Manufactured from high carbon hardened and tempered steel strip & stainless steel (STAR BRAND). The carefully rounded edges and highly polished thread eye ensure faultless, undisturbed weaving of fine and low twist warp yarns. Protected against rust by electro plating Available in Nickel plated finish , Zinc plated finish ,Golden yellow zinc platedADVANTAGES OF STAR BRAND Precision quality in punching, debburing, polishing and electroplating by using prime quality spring steel strip, latest machineries and techniques by expert technical hands. Wide variety of sizes and shape to choose for any particular optimum result. Smooth polished thread passing area improves over all life of Dropwires and improves fabric lusture which give better result in further process of fabric like processing, dyeing and printing. Fully scientifically controlled electroplating gives maximum rust protection life. Minimum delivery time for any special requirements. Precisely manufactured for automatic drawing in machine of any make.

1200 Bar Hydro Jetting Machine

100,000 Per piece

1 piece (MOQ)

HT1200 Rotary Grass Cutter

387,000 Per Piece

1 Piece (MOQ)

Fusing Machine

Get Price Quote

Roll To Roll Fabric Inspection Machine

Get Price Quote

The company holds expertise in manufacturing, exporting and supplying optimum quality Roll To Roll Fabric Inspection Machine. Clients can avail Roll To Roll Fabric Inspection Machine from us with rubber sleeve expander roll for crease free rolling and inverter control panel. Our Roll To Roll Fabric Inspection Machine is efficient in roll to roll inspection. Moreover, we are offering Roll To Roll Fabric Inspection Machine with adequate lighting system below and above the table.

Super Jumbo Jigger Machine S J 1000

Get Price Quote

1 Piece (MOQ)

SJ 1000 Saves Chemicals: Besides comparatively low liquor ratio, SJ 1000 has a pneumatic squeezing system, the temperature of the fabric is maintained at about 76 Degrees Celcius for a much longer period than in a normal Jumbo Jigger. This reduces times and saves chemical. SJ 1000 Saves Labour: SJ 1000 need one operator whereas 10 normal jiggers giving equivalent production needs 5 operators. If there are three shifts, saving would be equivalent to 15-3= 12 Operators / Day. SJ 1000 Saves Space: Space requirement of SJ 1000 is only about 18 Feet X 12 Feet, saving vital shop floor space against big space availing method of jiggers, Rope Bleaching, J-Box, Etc. SJ 1000 is a Quality Bleacher: Incase of SJ 1000, entire lot of fabric gets chemical treatment in one machine whereas in jiggers different lengths of one lot are treated where parameters of liquor ratio, temperature of bath, time durations are very likely to vary. Thus, inconsistent bleaching results are seen. SJ 1000 enjoys big clientelle in the textile industry on account pf features narrated in detail. Both Cotton Mills and Processing Houses have made it a point to replace their conventional methods of bleaching by Kiers,Jiggers, etc. and have gone in a big way for the installation of SJ 1000. The economy involved and the space saved has induced them to place repeat orders for more than one machine in almost all the cases. Extra Attachments (Optional) which enhance performance parameters of SJ 1000, 1) Hood. 2) Low Liquor Tank ( Type W 5 ). 3) Intensifier with high pressure pumps and filteration. 4) Auto Temperature regulator.

Cotton Wick Making Machine

13,000 Per Piece

1 Piece (MOQ)

Filament Spinning Machines

Get Price Quote

Filament Spinning Machines, offered by us, are used for spinning yarns and filaments. We offer a wide array of Filament Spinning Machines such as Spandex Filament Spinning Machine, Conjugate Filament Spinning Machine, FDY Filament Spinning Machine and POY Filament Spinning Machine. We have quality auditors who conduct several tests before purchasing the equipment. Thus, our customers are fully satisfied with our range of Filament Spinning Machines.

cotton ginning machinery

190,000 - 200,000 Per piece

1 piece (MOQ)

Double Roller Raw Cotton Ginning Machine 54" Jumbo Model make 'NATIONAL'. Only ginning machine with double sealed self aligned bearings. Inter changeability of parts. Oil immersed gearbox for long life of gears and bearings. NE 8 Steel material for most of the shaft and stud / pin duly tempered. Steel helical gear for contact ratio and noiseless working. Very less vibration and less where and tear. Motor power required 5 HP, 132 S Frame, 1440 RPM. Weight of the mission 1100 kg. Floor size 2230L x 1700W x 1170H (mm). Production capacity 70 - 80 kgs / 1HR (Approx), Row cotton processing capacity 190 - 275 Kgs / 1HR depending upon the quality of the Cotton and clean cotton. Distance between two machines 600mm. Operating speed 950 - 1000 RPM.

Non Woven Needle Punching Machine

460,000 Per Piece

1 Piece (MOQ)

Coil Slitting Machine

5,000,000 - 15,000,000 Per piece

1 Bag (MOQ)

Fabric Rotary Printing Machine

1,200,000 Per Piece

1 Piece (MOQ)

Fabric Rotary Printing Machine Chhoker & Sons is an inimitable entity in the industry, keenly committed to offering a most favourable quality range of Fabric Rotary Printing machines. We are working as a renowned Fabric Rotary Printing Machine Supplier and making the delivery without any delay. Our machines are manufactured according to set industry standards. The expertly manufactured products are made by our adroit professionals, making use of premium-grade components and the most modern technology. As an esteemed Fabric Rotary Printing Machine Trader, we assure smooth operation and fine printing features. The offered printing machine is broadly applauded among our clients. As a Fabric Rotary Printing Machine supplier, we first understand the demands of the customers and deliver the product as per their needs. If you need more information about Fabric Rotary Printing, you can contact our team.

Leather Skiving Machine

Get Price Quote

Opener Saw Ginning Machine

Get Price Quote

1 Piece (MOQ)

Iron Worker Machine

135,000 - 675,000 Per Piece

1 Piece (MOQ)

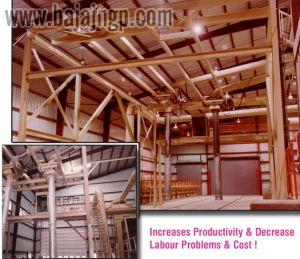

Bajaj ginning machinery available used and new

100,000 - 200,000 Per piece

Bajaj ginning machinery spare parts and machinery

Suction Command Seed Cotton Feeding System

Get Price Quote

1 Unit (MOQ)

Electro –Hydraulic Controlled Suction System for Cotton Modules, Wagons & Bulk Seed Cotton The Suction –Command System takes the worry out of finding dependable labour for suction feeding seed cotton from your trailers or modules. The standard system consists of two lanes independent suction lanes. Bajaj’s Suction – Command System can be designed to meet your individual needs from one to four suction lanes. Unlimited directional control is smooth and easy. The steel carriage assembly and the high strength aluminium telescopes are very responsive to the operator’s controls. Swing Momentum is always under control by the operator. The Suction Command operator cab is a clean , comfortable environment. 6 MAJOR DESIGN FEATURES Engineered for Strength with Less Weight. Stronger design in critical areas, yet total weight saved reduces wear and strain on track rails and entire structure. Thick Walled Aluminium Telescopes Stronger Tubes with less weight give better control and put less stress on the swing mechanism. Flexible Swivel Sleeve A positive, air tight fit provides efficient operation and requires minimum maintenance. Large Radius Elbows Choking is virtually eliminated Four Rubber Covered Carriage Wheels All wheels are powered delivering positive traction. Traverse travel is straight… no binding. Industrial Grade Hydraulic Cylinders Other Feature Hydraulic Power Cylinders Long Life Constructions Case Hardened Piston Rods Four Traversing Motors Per Unit Independent H beam Support Frame and Bracing All four carriage wheels are powered by the highest quality Hydraulic Traversing Motors Tapered Pistons Provide Cushion to reduce Shock Instantly available power when demanded and power cost savings when there is no demand.60 gallons ( 227.2 Litre) Fluid Capacity 15 gallons ( 56.8Litre) Per minute

Ultrasonic SE-H2012A Lace Making Machine

Get Price Quote

1 Piece (MOQ)

Ultrasonic Lace Sewing Machine, also could be called ultrasonic lace machine, ultrasonic sewing machine, is efficient sewing embossing device, use to sewing, welding, cutting and embossing synthetic fiber material. Processing without needle and thread, final products can be water tightness section without rough selvedge and smooth. Widely use to process clothing, toys, food and non-woven materials. Our company provide: ultrasonic lace sewing machine, double column type ultrasonic lace sewing machine and non-standard ultrasonic lace sewing machine to satisfy various industries’ requirement.” Your professional auto non-woven sewing cutting machinery designer.” is our declaration.Features and Function Ultrasonic welding without needle and thread, also can cut, sealing and embossing, welding effect strong cementation dint, waterproof artistic effect, high quality. Processing by ultrasonic and steel roller, no damage to mercery edge, no rough selvedge. This machine could be operated without pre-heating and has the advantage of continuous production. A general worker could operate the machine owes to the convenient and easy-understanding operation of this machine. Save cost, 5-6 times high productivity than traditional machine. Roller and Taiwan imported horn made of special alloy steel, roller’s pattern can design by client’s requirement, Taiwan imported horn stand wear and tear long using life, easy to replace roller and horn, core shift design, flexible adjusting, easy to adjust the horizontal.