YOKE WEIGHT LIFT TEST BLOCK (4.5KG)

2,000 Per Piece

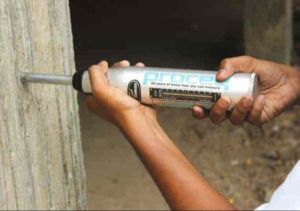

YOKE WEIGHT LIFT TEST BLOCK (4.5KG).Dimensions: Thickness based on customer requirements.Description: Yoke Test block for weightlifting (4.5kg)Raise testing weightsTo guarantee that parts are being thoroughly inspected while employing MPI methods of NDT Electromagnetic, weights must be used to test the magnetic field created by electro-magnets and permanent magnets. Useful Yoke Test Weight for AC Yokes 4.5Kg when using the carrying handle American Standard 18 kg Permanent Magnet Test Weight with Carrying Handle 22.5Kg.Material : Carbon steel.

...more

YOKE WEIGHT LIFT TEST BLOCK (18.0KG).

2,000 Per Piece

yoke weight lift test block (18.0kg).dimensions: thickness based on customer requirements.description: to guarantee that parts are being thoroughly inspected while employing mpi methods of ndt electromagnetic, weights must be used to test the magnetic field created by electro-magnets and permanent magnets. yoke use of a test weight with ac yokes 4.5kg when using the carrying handle american standard 18 kg permanent magnet test weight with carrying handle 22.5kg.material : carbon steel.

...more

V3 TEST CALIBRATION BLOCK

2,000 Per piece

V3 TEST CALIBRATION BLOCK.Dimensions: L X W X T (150mm X 90mm X 25mm). Description: For both laboratory and field calibration of ultrasonic fault detection equipment. This block is designed to replace V1 or IIW-Type Test Blocks with a smaller, lighter alternative. Geometry: A Includes engraved reference mark scales, 25mm,50mm, and 100mm radii, two 3.0mm diameter through holes, and a 0.4mm wide x 2.5mm deep slot. Material : Carbon steel,Stainless Steel,Titanium,Aluminum,Alloy Steel.

...more

V2 A4 CALIBRATION TEST BLOCK 20MM

2,000 Per piece

V2 A4 CALIBRATION TEST BLOCK 20MM.Dimensions: L X W X T (75mm X 43mm X 20mm) Description: For on-site verification of the miniature shear wave probe index, time basis, beam angle, and gain, a 20 mm thick small calibration block is used. includes etched reference mark scales from 35 to 75 degrees, a hole with a radius of 20 and 50mm, and a 1.5mm hole (or 5mm). Material : Carbon steel,Stainless Steel,Titanium,Aluminum,AlloySteel,Cupro Nickel,Inconel etc.

...more

V2 A4 CALIBRATION TEST BLOCK 12.5MM

2,000 Per piece

V2 A4 CALIBRATION TEST BLOCK 12.5MM.Dimensions: L X W X T (57mm X 43mm X 12.5mm). Description: For on-site verification of the miniature shear wave probe index, time basis, beam angle, and gain, a small calibration block measuring 12.5 mm thick is used. includes a 1.5mm hole (or 5mm) with a 12.5mm and 50mm radius, as well as reference mark scales from 35 to 75 degrees that are etched. Material : Carbon steel,Stainless Steel,Titanium,Aluminum,AlloySteel,Cupro Nickel,Inconel etc.

...more

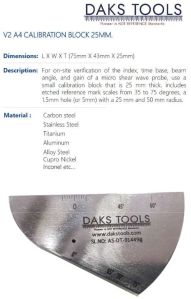

V2 A4 CALIBRATION BLOCK 25MM

2,000 Per piece

V2 A4 CALIBRATION BLOCK 25MM.Dimensions: L X W X T (75mm X 43mm X 25mm).Description: For on-site verification of the index, time base, beam angle, and gain of a micro shear wave probe, use a small calibration block that is 25 mm thick. includes etched reference mark scales from 35 to 75 degrees, a1.5mm hole (or 5mm) with a 25 mm and 50 mm radius.Material : Carbon steel,Stainless Steel,Titanium,Aluminum,AlloySteel,Cupro Nickel,Inconel etc.

...more

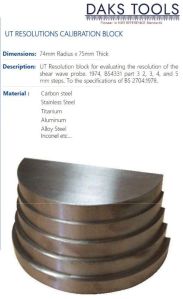

UT RESOLUTIONS CALIBRATION BLOCK

2,000 Per piece

UT RESOLUTIONS CALIBRATION BLOCK.Dimensions: 74mm Radius x 75mm Thick.Description: UT Resolution block for evaluating the resolution of the shear wave probe. 1974, BS4331 part 3 2, 3, 4, and 5mm steps. To the specifications of BS 2704:1978.Material : Carbon steel,Stainless Steel,Titanium,Aluminum,Alloy Steel,Inconel etc.

...more

usaf general purpose eddy current standard test block

2,000 Per Piece

usaf general purpose eddy current standard test block.dimensions: l x w x t (7.0” x 4.0” x 1.06”).description: test block for the usaf general purpose eddy current standard usaf general purpose eddy current standard. a (3) plate assembly with (66) edm notches distributed among the (20) fastening holes.material : carbon steel,stainless steel,titanium,aluminum,alloy steel etc.

...more

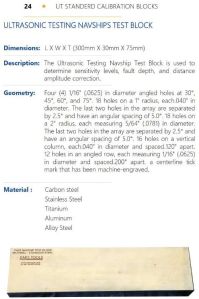

ULTRASONIC TESTING NAVSHIPS TEST BLOCK

2,000 Per piece

ULTRASONIC TESTING NAVSHIPS TEST BLOCK.Dimensions: L X W X T (300mm X 30mm X 75mm).Description: The Ultrasonic Testing Navship Test Block is used to determine sensitivity levels, fault depth, and distance amplitude correction.Geometry: Four (4) 1/16" (.0625) in diameter angled holes at 30°,45°, 60°, and 75°. 18 holes on a 1" radius, each.040" in diameter. The last two holes in the array are separated by 2.5° and have an angular spacing of 5.0°. 18 holes on a 2" radius, each measuring 5/64" (.0781) in diameter. The last two holes in the array are separated by 2.5° and have an angular spacing of 5.0°. 16 holes on a vertical column, each.040" in diameter and spaced.120" apart. 12 holes in an angled row, each measuring 1/16" (.0625) in diameter and spaced.200" apart. a centerline tick mark that has been machine-engraved.Material : Carbon steel,Stainless Steel,Titanium,Aluminum,AlloySteel.

...more

ultrasonic testing corrosion erosion plate

2,500 Per Piece

Ultrasonic Testing Corrosion, Erosion, Plate Thickness 25MMDimensions: Length 300mm X Width 200mm Thickness 25mmTolerance: +/- 2mmSpecimen: PlateFlaws: Defects Were Placed Randomly On The Specimens. Some Of Specimens Will Have Naturally Obtained.Documentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material: Carbon steelStainless Steel

...more

Tubular Nodes12mm, 30deg UT Flawed Specimens (As per BINDT PCN Classification Specimens)

8,000 Per Piece

Tubular Nodes 12mm 30deg UT Flawed Specimens ( As per BINDT PCN Classification Specimens ) Dimensions : Tubular Nodes Dihedral Angle 30deg Main Pipe Segment 508mm Dia. 20 to 25 mm WT & Branch 152mm Dia. And 12 mm WT (Carbon Steel) Material : Carbon Steel Flaws : 3 per specimen, Randomly placed Specimen Tolerance: +/- 2mm Documentation: NDT Verification Reports And CAD Drawings and Test Sheets.

...more

Tubular Nodes 15mm 70deg Ut Flawed Specimens (As Per Bindt Pcn Classification Specimens)

5,000 Per Piece

TUBULAR NODES 15MM 70ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)Dimensions: Tubular Nodes Dihedral Angle 70ᵒ Main Pipe Segment 500mm Dia. 20 to 25 mm WT & Branch 200mm Dia. And 15mm.Tolerance: +/- 2mmSpecimen: Tubular NodesFlaws: 3 per specimen, Randomly placed SpecimenDocumentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material: Carbon steel.

...more

TUBULAR NODES 15MM 70 DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS )

2,000 Per Piece

TUBULAR NODES 15MM 70ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS ).Dimensions:Tubular Nodes Dihedral Angle 70ᵒ Main Pipe Segment 500mm Dia. 20 to 25mm WT & Branch 200 Dia. And 15mm. Tolerance: +/- 2mm. Specimen: Tubular Nodes. Flaws: 3 per specimen, Randomly placed Specimen. Documentation: NDT Verification Reports And CAD Drawings and Test Sheets. Material : Carbon steel.

...more

TUBULAR NODES 15MM 60Deg UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,500 Per Piece

TUBULAR NODES 15MM 60Deg UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)Dimensions: Tubular Nodes Dihedral Angle 60ᵒ Main Pipe Segment 500mm Dia. 20 to 25 mm WT & Branch 200 Dia. And 15mm.Tolerance: +/- 2mmSpecimen: Tubular NodesFlaws: 3 per specimen, Randomly placed SpecimenDocumentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material: Carbon steel.

...more

TUBULAR NODES 15MM 60 DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,000 Per Piece

TUBULAR NODES 15MM 60ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS).Dimensions:Tubular Nodes Dihedral Angle 60ᵒ Main Pipe Segment 500mm Dia. 20 to 25mm WT & Branch 200 Dia. And 15mm. Tolerance: +/- 2mm. Specimen: Tubular Nodes. Flaws: 3 per specimen, Randomly placed Specimen. Documentation: NDT Verification Reports And CAD Drawings and Test Sheets. Material : Carbon steel.

...more

TUBULAR NODES 15MM 40DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,000 Per Piece

tubular nodes 15mm 40ᵒ ut flawed specimens (as per bindt pcn classification specimens).dimensions: tubular nodes dihedral angle 40ᵒ main pipe segment 500mm dia. 20 to 25mm wt & branch 200 dia. and 12mm. tolerance: +/- 2mm. specimen: tubular nodes. flaws: 3 per specimen, randomly placed specimen. documentation: ndt verification reports and cad drawings and test sheets. material : carbon steel.

...more

tubular nodes 15mm 45 degree ut flawed specimens

2,000 Per Piece

TUBULAR NODES 15MM 45ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS).Dimensions:Tubular Nodes Dihedral Angle 45ᵒ Main Pipe Segment 500mm Dia. 20 to 25mm WT & Branch 200 Dia. And 15mm. Tolerance: +/- 2mm. Specimen: Tubular Nodes. Flaws: 3 per specimen, Randomly placed Specimen. Documentation: NDT Verification Reports And CAD Drawings and Test Sheets. Material : Carbon steel.

...more

Tubular Nodes 15mm 40 Deg UT Flawed Specimens ( As per BINDT PCN Classification Specimens )

2,500 Per Piece

TUBULAR NODES 15MM 40ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)Dimensions: Tubular Nodes Dihedral Angle 40ᵒ Main Pipe Segment 500mm Dia. 20 to 25 mm WT & Branch 200 Dia. And 12 mm.Tolerance: +/- 2mmSpecimen: Tubular NodesFlaws: 3 per specimen, Randomly placed SpecimenDocumentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material: Carbon steel.

...more

TUBULAR NODES 15MM 35DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,000 Per Piece

TUBULAR NODES 15MM 35ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS).Dimensions: Tubular Nodes Dihedral Angle 35ᵒ Main Pipe Segment 500mm Dia. 20 to 25mm WT & Branch 200mm Dia. And 12mm. Tolerance: +/- 2mm. Specimen: Tubular Nodes. Flaws: 3 per specimen, Randomly placed Specimen. Documentation: NDT Verification Reports And CAD Drawings and Test Sheets. Material : Carbon steel.

Finishing : Polished

...more

tubular nodes 12mm 45degree ut flawed specimens

2,000 Per Piece

TUBULAR NODES 12MM 45ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS). Dimensions: Tubular Nodes Dihedral Angle 45ᵒ Main Pipe Segment 20” Dia. 20 to 25mm WT & Branch 152 Dia. And 10mm. Tolerance: +/- 2mm. Specimen: Tubular Nodes. Flaws: 3 per specimen, Randomly placed Specimen. Documentation: NDT Verification Reports And CAD Drawings and Test Sheets. Material : Carbon steel.

...more

Tubular Nodes 12mm 45Deg UT Flawed Specimens (As per BINDT PCN Classification Specimens)

2,500 Per Piece

TUBULAR NODES 12MM 45ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)Dimensions: Tubular Nodes Dihedral Angle 45ᵒ Main Pipe Segment 20” Dia. 20 to 25 mm WT & Branch152 Dia. And 10 mmTolerance: +/- 2mmSpecimen: Tubular NodesFlaws: 3 per specimen, Randomly placed SpecimenDocumentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material: Carbon steel.

...more

TUBULAR NODES 12MM 40DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,000 Per Piece

TUBULAR NODES 12MM 40ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS). Dimensions: Tubular Nodes Dihedral Angle 40ᵒ Main Pipe Segment 500mm Dia. 20 to 25mm WT & Branch 152mm Dia. And 12mm. Tolerance: +/- 0.080” (2.032mm). Specimen: Tubular Nodes. Flaws: 3 per specimen, Randomly placed Specimen.Documentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material : Carbon steel.

...more

TUBULAR NODES 12MM 35DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,000 Per Piece

tubular nodes 12mm 35ᵒ ut flawed specimens (as per bindt pcn classification specimens).dimensions: tubular nodes dihedral angle 35ᵒ main pipe segment 20” dia. 20 to 25mm wt & branch 152mm dia. and 12mm.tolerance: +/- 2mm.specimen: tubular nodes.flaws: 3 per specimen, randomly placed specimen.documentation: ndt verification reports and cad drawings and test sheets.material : carbon steel.

...more

TUBULAR NODES 12MM 30DEGREE UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS)

2,000 Per Piece

TUBULAR NODES 12MM 30ᵒ UT FLAWED SPECIMENS (AS PER BINDT PCN CLASSIFICATION SPECIMENS).Dimensions: Tubular Nodes Dihedral Angle 30ᵒ Main Pipe Segment 508mm Dia. 20 to 25mm WT & Branch 152mm Dia. And 12mm.Tolerance: +/- 2mm.Specimen: Tubular Nodes.Flaws: 3 per specimen, Randomly placed Specimen.Documentation: NDT Verification Reports And CAD Drawings and Test Sheets.Material : Carbon steel.

...more

vacuum box leakage testing service

10,000 Per Day

Vacuum Box Testing of butt, fillet and lap weld Vacuum box testing is a non-destructive examination (NDE/NDT) used for locating welding leaks. A vacuum box and a compressor create a high or low-pressure vacuum and a detergent solution is applied to the test area. The detergent bubbles help to identify the leaks within the created pressure envelope. The main objective of the Vacuum box testing technique is to locate leaks in welds due to through-thickness discontinuities. This is accomplished by applying a solution to a weld and creating a differential pressure across the weld causing the formation of bubbles as leakage gas passes through the solution. This testing is to be performed prior to any main vessel or tank testing following the completion of all welding. This article will briefly explain the leak testing procedure using the vacuum box method that can be used for all metals. Required Equipment for Vacuum Box Testing Vacuum box test method employs the following equipment for welding checks a compressor: approximate flow 6 m^3 per minute under 7 bar An air pipe between the compressor and vacuum box. A vacuum box, which enables to obtain a depression of 500 m-bar, which can be controlled by means of a vacuum manometer located on the box. The manometer shall have a range of 0 psi (0 m-bar) to 15 psi (1020 m-bar). A liquid detergent mixed with water makes soapy water. Bubble solution which produces a film. That does not break away from the area to be tested and the bubbles formed shall not break rapidly due to air drying or low face tension. Soups or detergents for cleaning shall not be used. If the ambient temperature is below freezing, add ethylene glycol to the solution (antifreeze). General lighting or individual lighting if necessary. The minimum light level shall be 100 foot-candles (1000 lux) A brush (diameter not less than 50 mm) A metallic brush and/or a grinding machine.

...more

Vacuum Box Leak Testing

1,000 Per Day

We are ranked amongst the renowned organizations that are engaged to provide the best quality Vacuum Box Leak Testing Service. The offered service is executed by our highly qualified professionals using premium grade machines and latest technology. Our skilled professionals properly examine all the parameters associated to this service and carry out it in the best possible manner. Further, the provided service is performed as per the clients’ specific needs with respect to their budgetary constraints.

...more

Ultrasonic Thickness Measurement (utm)

1,000 Per Day

Ultrasonic thickness measurement (UTM) is a non-destructive testing method used to inspect the metal thickness of ship hulls, piping and structural steel. Thickness measuring is essential across many industries to monitor corrosion, erosion and damage. Ultrasonic thickness measurement (UTM) is commonly used and the method can be applied to a wide range of structures and components that includes ship hulls, piping, pressure vessels and structural steel. Detection of metal loss caused by corrosion, erosion or damage is vital to ensure the continued safety and operation of the inspected item/structure. It can also help determine if repair work or replacement is needed or if the item/structure should be retired. Ultrasonic thickness measurement data gives customers the necessary information required to determine if the tested item has the adequate metal thickness for which it was designed. An ultrasonic thickness gauge works by precisely measuring how long it takes for a sound pulse that has been generated by a small probe called an ultrasonic transducer to travel through a test piece and reflect back from the inside surface or far wall. From this measurement, the thickness of the test piece is calculated and displayed on a digital screen. The portability of the testing equipment allows for on-site inspection and results are instant. If a problem has been detected by the technique, additional non-destructive testing methods can be used to further investigate the findings. Alpha Sonix inspectors are highly experienced in performing ultrasonic thickness measurements and corrosion evaluations for all industry sectors including oil and gas, power generation, structural contractors and foundries. In addition, Alpha Sonix provides Total Quality Assurance solutions for all your thickness gauging and corrosion monitoring requirements as we can perform follow-up non-destructive testing to further investigate results. Our commitment to responsive turnaround times will ensure that we meet your schedules and our expertise means we guarantee your components are tested to industry standards, codes or customer specifications.

...more

Ultrasonic Thickness Gauge Testing

3,000 Per Day

Ultrasonic Thickness Gauge Testing

Ultrasonic Testing

1,000 Per Day

Manual Ultrasonic Testing MANUAL ULTRASONIC TESTING Manual ultrasonic testing is a form of NDT used to detect internal discontinuities, material thickness, and part integrity. Ultrasonic testing is used to carry out the inspection in casting, forging, welded components in all industrial sectors. The method can be performed on all types of materials: · Defects that are small and deep in the surface. · To detect object thickness. · Assessment of part integrity. Its major advantage is quick and portable inspection. Alpha Sonix uses advanced ultrasonic equipment and we can inspect customers’ components and structures according to industry codes and standards or customer specifications, ensuring that components or structures meet the highest quality standards for safety and reliability. We offer both off-site and on-site ultrasonic testing. The technique uses a pulse unit to power an ultrasonic transducer. The transducer is placed into contact with the tested object with a thin layer of Couplant and sound waves are generated into the object. The reflected waves are assessed and the signals from the echo are shown on the display unit. Skilled interpretation of the signals indicates if there are any defects or discontinuities. Our experienced ultrasonic inspectors are certified according to industry standards in ASNT level 2 and 3. They offer guidance in the selection of suitable testing methods and regiment. By choosing Alpha Sonix for your ultrasonic testing, we can meet your production and maintenance schedules. And our highly experienced inspectors use advanced equipment to give you the Total Quality Assurance that your products or components are compliant with industry standards. Other advanced ultrasonic testing methods provide by Alpha Sonix: Alpha Sonix not only provide manual ultrasonic testing, but we also offer advanced ultrasonic testing that includes: · Time of flight diffraction (TOFD) · Ultrasonic Thickness Measurement · Phased array · Immersion ultrasonic testing

...more

Time Of Flight Diffraction

15,000 Per piece

TIME OF FLIGHT DIFFRACTION (TOFD)Welding flaws can compromise the welded structure’s stability and integrity. When it comes to testing welds, Time of Flight Diffraction (TOFD), high-performance non-destructive testing (NDT) technique, provides accurate detection and sizing of cracks, slag, and lack of fusion in true wall direction, allowing you to access the vessel’s life. We will be with you throughout your testing project and will provide you with tailored solutions. Weld testing using the TOFD technique, data processing, and report preparation using the developed software are all part of our capabilities. We believe that using our TOFD inspection service will result in significant time savings throughout the life cycle of new construction and replacement projects. It is an excellent and widely accepted pre-service and in-service inspection tool that is recognized internationally, with defined codes, standards, and acceptance criteria available for its use.

...more

third party inspections

2,000 Per requirement

Our Integrated Third-Party Inspection team represents interest of client throughout the project and our service ensures right & cost-effective solutions for the project requirements. We are providing the services by our experienced AWS/CSWIP/NACE /BGAS certified inspectors to carry out QA QC inspection as mentioned our scope below to our esteemed client with excellent customer satisfaction

...more

RLA & Condition Assessment Of Boilers

5,000 Per Day

Residual/Remaining Life Assessment (RLA) & Condition Assessments of BoilersConsidering the operational conditions to which the equipment is subjected, determining the remaining life of an asset necessitates a thorough understanding of the degradation mechanisms and their progression.RLA assessments are performed by ALPHA SONIX in the most difficult markets. ALPHA SONIX uses advanced analytical and simulation techniques in addition to its multidisciplinary in-house team to give accurate results and superior value to the decision-making process.Many businesses and power plants have the challenge of predicting the remaining operational life of plant equipment that has been in use for many years. The issue is particularly acute for businesses with plants that have been in operation for 15 to 25 years or longer.In the maintenance decision-making process, reliability data analysis is critical. The ability to accurately estimate the remaining life of equipment and system components can be a valuable asset when planning preventative maintenance. To achieve high operational availability and maintenance stability in order to extend the life of equipment. BOILER AND ITS COMPONENTS CONDITION EVALUATION RLA is a method/test for inspecting and testing boilers and heaters that have been in use for a long time. RLA is a maintenance tool that can be used to predict and avoid problems before they occur. Using both non-destructive and destructive procedures, condition assessment is carried out to determine the current status of component property degradation. Condition evaluation is critical for keeping facilities running smoothly and meeting increasingly demanding environmental laws, planned outages, adequate maintenance, and data collecting in new and old plants alike. Rather of being a one-time event, it is a continuous process. Approach to Determining How Much Time Is Left In My Life 1. Determining the true process of degradation • High Cycle Fatigue • Low Cycle Fatigue • Thermal Fatigue • Thermo Mechanical Fatigue • Thermal Aging • Wear • Creep • Embitterment • Corrosion 2. Physical Property Visual Inspection 3. Nondestructive testing (NDT) that includes in-situ metallography, ultrasonic testing, magnetic particle inspection, DP testing, and ferrite measurement. 4. Stress analysis: To determine the material's strength and check for ruptures. 5. Non-Destructive Testing (NDT): To determine the component's integrity. 6. Laboratory testing: To provide useful information regarding the material's structural integrity. 7. Equipment fitness assessment: based on data provided.8. Maintenance Suggestions: If necessary, equipment repair is recommended to extend its life.9. Remaining Life Judgment Based on Analysis: Estimates for remaining life are made. In addition, periodic inspection processes are written out to keep track of the equipment's health while it's in use.

...more

Risk Based Inspection Services

10,000 Per Day

The oil and gas, as well as the petrochemical industries, are under constant pressure to decrease risks and enhance safety and environmental challenges. Owners continue to make ongoing efforts to minimise production costs and improve maintenance procedures.In the hydrocarbon and chemical process sectors, as well as offshore pressure systems, the ALPHA SONIX team has extensive expertise designing risk-based inspection (RBI) procedures on fixed equipment and pipelines. These programmes are based on API RP 580, API RP 581, DNV-RP-G101, and best engineering practises and client specifications, as well as API RP 580, API RP 581, and DNV-RP-G101. Software and technology implementation are used to supplement the programmes.WHAT IS RISK-BASED INSPECTION (RBI) AND HOW DOES IT WORK?Risk-Based Inspection (RBI) is an analysis methodology and process that, unlike condition-based inspection, necessitates a qualitative or quantitative assessment of the probability of failure (PoF) and consequence of failure (CoF) associated with each equipment item in a process unit, including piping circuits. Individual pieces of equipment are categorised by their hazards in a fully implemented RBI programme, and inspection activities are prioritised according on this category. A proper inspection and maintenance programme is then designed based on an estimate of the possibility and implications of failure associated with each piece of equipment, component, or structure.WHAT IS THE IMPORTANCE OF RISK-BASED INSPECTION AND MAINTENANCE?RBI is used to detect and comprehend risk, risk drivers, and the lifecycle of equipment. RBI can determine whether an inspection is required; however, this requires additional data that is highly targeted in order to reduce the underlying uncertainties connected with the hazards associated with the equipment's existing and expected damage status. When an inspection will not improve knowledge of the damage situation, RBI should not be used to recommend it. RBI should highlight to alternate risk mitigation measures such as replacement, repair, or other activities that satisfy the risk criteria in those circumstances where PoF is driving the risk.RBI is critical for maximising the efficiency of industrial plants in a variety of industries. It enables you to meet the industry's financial, dependability, and regulatory requirements by enhancing the performance, availability, and safety of your facility. It establishes a long-term testing and inspection programme, which extends the life of your plant.

...more

Remote Visual Inspection / Videoscopy

10,000 Per Day

Borescope / Remote Visual InspectionRemote Visual Inspection, also known as RVI or RDVI, is a type of visual inspection that employs visual aids such as video technology to allow an inspector to examine things and materials from a distance because they are inaccessible or in hazardous conditions. RVI is a sub-discipline of non-destructive testing (NDT). Borescopes, videoscopes, fiberscopes, push cameras, pan/tilt/zoom cameras, and robotic crawlers are just a few of the technologies available. Remotes are widely employed when distance, angle of view, and limited lighting make direct visual investigation difficult, or when access is restricted due to time, money, or weather threats.RVI/RDVI is often used to examine the "health" and operability of fixed and movable assets as a predictive maintenance or regularly scheduled maintenance tool. Inspection coverage, repeatability, and data comparison are all improved by RVI/RDVI. Due to physical size limits or potential safety considerations associated to the inspection environment, the "remote" element of RVI/RDVI refers to the operator not accessing the inspection area.Solutions for Visual InspectionOlympus borescopes and visual inspection equipment are portable, intelligent solutions that match the demands of current industrial inspections when you need to inspect difficult-to-access locations. Our remote visual inspection solutions are versatile for a variety of applications thanks to a plethora of innovative, intuitive features and a wide selection of borescope, videoscope, and fiberscope lengths, diameters, and viewing possibilities.Applications Engines for aeroplanes (turbofan, turbojet, turboshaft). The fuselage of an aeroplane. Turbines for generating electricity (steam and gas). pipework for the manufacturing process (oil and gas, pharmaceutical, food preparation). Contaminated locations around nuclear power plants. Any place that is too risky, small, or expensive to observe directly. Advantages Access to subject areas requires less mechanical disassembly. NDT is less expensive than other types of testing. Reduced equipment shutdown times and quicker equipment reinstallation. Compared to manual inspection procedures, there are less safety limits. Equipment condition can be monitored more quickly and accurately throughout its life cycle. Prior to critical maintenance, a better assessment of condition and timing is required. Faults can be identified, located, and isolated more quickly.

...more

Remote Field Eletromangnetic Testing

50,000 Per Day

In the realm of non-destructive testing, remote field testing, or "RFET," is one of numerous electromagnetic testing procedures routinely used. Magnetic flux leakage, conventional eddy current, and alternating current field measurement testing are some of the other electromagnetic inspection methods. Remote field testing is frequently referred to as "Remote Field Electromagnetic Testing" since it is related with eddy current testing. However, there are a few key distinctions between eddy current and remote field testing that will be discussed in this section.Due to the substantial skin effect in ferromagnetic materials, standard eddy current techniques have difficulties inspecting the complete thickness of the tube wall. RFET is primarily used to inspect ferromagnetic tubing.For example, utilising traditional eddy current bobbin probes to inspect a 10 mm thick steel pipe (such as those found in heat exchangers) would necessitate frequencies about 30 Hz to obtain appropriate I.D. to O.D. penetration into the tube wall. Because of the low frequency, the sensitivity of fault detection is quite low. The use of partial saturation eddy current probes, magnetically biassed probes, and pulsed saturation probes can theoretically improve the degree of penetration.These specialised eddy current probes, however, are still limited in their examination capabilities due to the enormous amount of metal present as well as potential permeability fluctuations inside the product.The employment of the remote field-testing approach can substantially reduce the challenges encountered in the testing of ferromagnetic tubes. The advantage of the RFET approach is that it allows for approximately similar detection sensitivities on both the inner and outer surfaces of a ferromagnetic tube. Variations in wall thickness are very sensitive to the approach, although fill-factor changes between the coil and tube are less sensitive. When checking conducting tubular products, RFET can be employed, but it is typically thought to be less sensitive than traditional eddy current procedures.This is a quick and accurate screening tool for determining the condition of ferrous tubing (carbon steel, ferritic stainless steel and Duplex). It can inspect up to 12 mm (1/2 in.) of carbon steel tubing at very low frequencies (100 Hz to 1 kHz) and very high signal gains (> 80 dB). For most examinations, two channels are used: absolute for wall thinning and differential for localised abnormalities. RFT is excellent at measuring wall thinning but not so good for pitting (as compared to ECT). Cleaning the internal bore of tubes with any type of water jet lancing equipment is always recommended to improve inspection findings. Merits of RFET Tube Inspection Suitable for ferromagnetic tubes such as those found in heat exchangers and boilers. Localized corrosion, Pittings. Equally sensitive to internal and external flaws. Can inspect tubes up to 75mm OD with 5mm thickness. Relatively insensitive to probe liftoff or wobble. Typical pull speed between 6” and 12” per second.

...more

Rebound Hammer Testing Services

6,000 Per Day

Rebound hammer test is conducted to find out the compressive strength of concrete by using rebound hammer. The rebound of an elastic mass depends upon the hardness of the surface when it strikes. When the plunger of rebound hammer test is pressed against the surface of the concrete, the mass rebounds and the extent of such a rebound depends upon the surface hardness of the concrete. The spring-loaded hammer must travel with a consistent and reproducible velocity. The rebound distance of the steel hammer from the steel plunger is measured on a linear scale attached to the frame of the instrument. The tests can be performed in horizontal, vertically upward, vertically downward or any intermediate angled positions in relation to the surface. The devices are furnished with correlation curves by the manufacturer. ASTM C805 now states that these references to the relationship between the rebound hammer and compressive strength provided by the manufacturer shall be used only to provide indications of relative concrete strength at different locations in a structure. To obtain greater accuracy of test results, it is recommended that the user develops a correlation for the device on each concrete mixture design to be tested and at the intended test angle. Procedure to extract the appropriate result: Prior to the test, the rebound hammer should be tested against the anvil to get reliable results for which the manufacturer of the rebound hammer. indicates the range of readings on the anvil, suitable for different types of rebound hammer. On applying light pressure on the plunger, it will release it from the locked position and allow it to extend to the ready position for the test. Press the plunger to the surface of the concrete, the instrument being used perpendicular to the test surface. Apply a gradual increase in pressure until the hammer impacts. Take an average of about 15 readings.

...more

radiography testing service

3,500 Per Day

Being a prominent firm in this domain, we are engaged in offering Radiography Testing Services.Offered service is performed under the strict supervision of our experts using optimum grade tools and latest technology. Our professionals perform this service as per the requirements of our clients. Moreover, this service can be availed by our clients at most reasonable price.

...more

Positive Material Identification

8,000 Per Day

A fast and non-destructive testing (NDT) method for verifying the chemical composition of metals and alloys. PMI can be used to verify that supplied materials conform to the proper standards and specifications.

...more

Phased Array Ultrasonic Testing(PAUT)

1,000 Per Day

Phased array ultrasonic testing(PAUT) can be used for a multitude of tasks. Today in the assessment of structures, flaws, fitness for use of the product or equipment, and assessment of critical parts require flaw data regarding location shape and size of the defect. PAUT can provide an accurate assessment of defect and material fracture analysis based on accepted standards. PAUT is used to detect defects that can’t be easily detected using conventional volumetric methods such as radiography and manual ultrasonic testing. Alpha Sonix specializes in providing PAUT support in petrochemical industries, oil, and gas, power, chemical industries. This method also finds applications in pressure vessels and structural welded components providing a high standard of quality assurance, when time-restricted inspections are necessary. A PAUT probe is made up of multiple small ultrasonic probes which can be fired individually. By varying the time of the pulse of each probe ultrasonic rays can be steered into various angles and focal distances. Therefore, waves can be swept across the material and thereby covering the object. Applications for PAUT: · Inspection of forging or casting materials · Weld inspection · Corrosion mapping · Scanning complex geometry PAUT can detect: · Weld defects such as lack of fusion, slag inclusions, porosity, cracks, lack of penetration. · Erosion or corrosion. · Inherent discontinuities due to the manufacturing process used. · Environmentally damage. PAUT has several advantages in comparison to other NDT. Information received can be displayed in a variety of formats like A, B, C scans for reliable and faster inspections. This data can be stored and reviewed later as the need arises. With the PAUT shutdown requirement is eliminated hence effect on the product is minimal. ALPHA SONIX’s PAUT inspectors are highly qualified, holding a minimum of ASNT (American Society of Non-destructive Testing) Level II. Our inspectors are highly qualified to inspect tubes such as condensers, AC tubes, heat exchangers that require special equipment and highly skilled inspectors. Alpha Sonix Inspector is more than capable of running such tasks while the highest level of consumer satisfaction.

...more

Oxide Scale Thickness Measurement

20,000 Per Day

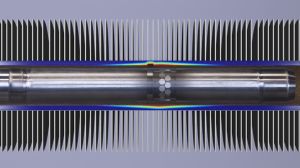

The ID oxide scale is produced by oxidation in the reheater and superheater. The scale build up occurs when the tubes have experienced high temperatures for extended periods of time. The formation of ID scale reduces heat transfer and results in a further increase of tube metal temperature. Higher temperatures promote further growth of ID scale. The result is the ID scale feeds on itself and increases in thickness as it continues to grow. The increase in ID scale and the associated tube metal temperature promotes creep in the tube metal. Formation of creep results in a loss of strength at high temperature and therefore a loss in remaining life. The final outcome of excessive scale is a thick lipped, long term overheat failure. Ultrasonic technique The ultrasonic method for measuring scale thickness is based on transmitting a wave through the tube thickness. The thickness is calculated by measuring the time difference between the signals reflected from the steel/scale interface and the tube ID surface. With advanced signal interpretation techniques, we can achieve Oxide scale Thickness measurements up to the resolution of 0.15 Microns. At Alpha Sonix NDT Solution Pvt. Ltd. we use Advanced Ultrasonic Equipment’s and recommended accessories to perform Internal Oxide Scale Thickness measurements to ensure accuracy and repeatability. Theory The very high temperatures found inside steam boilers (in excess of 1500 degrees Fahrenheit or 800 degrees Celsius) can cause the formation of a specific type of hard, brittle iron oxide called magnetite on the inside and outside surfaces of steel boiler tubing. At very high temperatures, water vapor will react with the iron in the steel to form magnetite and hydrogen. The speed of this reaction increases with temperature. Oxygen atoms will diffuse inward through the magnetite layer, and iron atoms will diffuse outward, so the scale continues to grow even after the tube surface is completely covered. Magnetite scale acts as thermal insulation on the pipe, since the thermal conductivity of scale is only about 5% that of steel. When heat can no longer transfer efficiently from the flame through the tube into the steam inside, the tube wall will heat up to temperatures beyond the intended operating range. Long term exposure to overly high temperatures, combined with the very high pressure inside the tube, leads to intergranular micro-cracking in the metal and to creep deformation (a slow swelling or bulging of the metal), which in turn eventually leads to tube failure by bursting. A secondary issue is oxide exfoliation, in which pieces of oxide scale break off (usually due to thermal stresses during boiler startup or shutdown). These hard pieces will be carried by the steam flow into the turbine, where over time they will cause erosion damage. The growth of magnetite scale and the associated metal damage are primary limiting factors with respect to boiler tube service life. The process begins slowly and then accelerates, for as the scale grows thicker the tube wall becomes hotter, and that in turn increases the rate of both scale growth and metal damage. Studies in the power generation industry have indicated that the effect of scale is relatively insignificant up to thicknesses of approximately 0.012 in. or 0.3 mm, but that beyond that thickness the negative effects of scale increase rapidly. Periodic measurement of scale thickness allows a plant operator to estimate remaining tube service life and to identify and replace tubes that are approaching the failure point. Ultrasonic testing provides a quick and nondestructive method for measuring scale. In all cases the coupling surface must be smooth and in some cases surface preparation will be required.

...more

near field testing service

1,500 Per Day

Near Field Testing (NFT) is a quick and low-cost approach for inspecting fin-fan carbon-steel tube. This method is based on a straightforward driver-pickup eddy current probe design that allows for quick signal analysis. Internal corrosion, erosion, and pitting in carbon steel tubing can all be detected with NFT. The NFT probes translate lift-off, also known as "fill factor," into amplitude-based signals. The fin geometry on the outside of the tube has no effect on NFT probes since eddy-current penetration is limited to the tube's inner surface.NFT Inspection's Benefits Electromagnetic testing procedures are slower than NFT. During NFT, there is no need for an external reference coil. Support plates and Tube sheets have no effect on NFT findings.

...more

Near Field Array Tube Inspection

10,000 Per Day

Near Field Array (NFA) tube testing is an electromagnetic testing method for detecting discontinuities on the internal surface of fin-fan type tubes and ferromagnetic (Carbon steel) heat exchanger tubes.NFA – Near field Array testing uses an array of coils (up to 30 coils) that activate in sequences, similar to ECA – Eddy current array testing. Unlike traditional Eddy current testing, which only uses a bobbin coil, NFA – Near field Array testing includes tangential coils that help gather detailed data and discontinuities in all directions.The most efficient test method for examining Aluminum finned carbon steel tubes is NFA – Near field Array tube testing. Because the external aluminium fins interfere with the quality of the signals acquired, aluminium finned carbon steel tubes are the most difficult to check. Internal pitting, internal cracks at the tubesheet, internal erosion, and the resulting wall loss can all be detected with NFA – Near field Array tube testing, which can also discriminate the location and size of discontinuities.For signal analysis and reporting,This NFA method is:Fast, Accurate, Traceable, and Archivable a digital paper trailLMATS employs Eddyfi's Magnifi software. The software allows NFA – Near field Array tube testing data to be shown and reported in 2D and 3D 'C' scan formats, which can help asset owners make informed decisions based on the accurate position and precision of the discontinuity. Ideal Applications: Most ideal for efficient and reliable inspection of Aluminum finned tubes and ferromagnetic heat exchangers NFA – Near field Array tube testing is ideal for inspecting tubes in the range of 19.05mm to 38.10mm diameter NFA – Near field Array tube testing is ideal for detecting internal diameter discontinuities such as pitting, cracks at tube sheet, erosion and wall loss on finned heat exchanger ferromagnetic tubes. Advantages: NFA – Near field Array tube testing can provide 2D and 3D ‘C’ scan images to assist the asset owner to locate exact location of the discontinuity and its precise size NFA – Near field Array tube testing can precisely measure volumetric discontinuities of approximately 3mm in a single pass NFA – Near field Array tube testing can detect both axial and circumferential cracks NFA – Near field Array tube testing can be performed comfortably at 6meters per minutes enabling to reduce downtime of the heat exchanger maintenance NFA – Near field Array tube testing does not use magnets and hence the pull speed does not affect the sensitivity s compared to MFL -Magnetic flux leakage technique NFA – Near field Array tube testing does not use water (Unlike IRIS – Internal Rotary Inspection System) and hence post cleaning and drying is not required minimizing the risk of water contamination pitting.

...more

NDT Visual Testing Service

5,000 Per Day

With enriched industrial experience and knowledge, we are providing a qualitative NDT Visual Testing Service. The provided service is executed as per the requirements of our precious clients. Our experts check all the steps and parameters associated to this service and carry out it in the best possible manner. Our professionals use high grade tools and latest technology to execute this service. Furthermore, the offered service can be availed by our precious clients at most reasonable price.

...more

ndt consultancy services

10,000 Per onwards

NDT stands for Non-Destructive Testing. It refers to an array of inspection methods that allow inspectors to evaluate and collect data about a material, system, or component without permanently altering it.

...more

magnetic particle testing service

1,000 Per test

Magnetic Particle Inspection (MPI) is an NDT method that can use magnetism to detect surface and subsurface discontinuities in ferromagnetic materials. MPI is generally used to determine parts fitness for use. It is a relatively easy and quick method that is widely used in various sectors such as automotive, oil and gas, aerospace, petroleum, power generation, etc. This method detects surface or subsurface discontinuities such as cracks, porosity, laps, seams, inclusions in ferromagnetic materials. One of the major advantages of this method is, it is a relatively fast method and gives an immediate indication on the surface. This method works by inducing the magnetic flux in the part to be tested. If any discontinuities or detect is present on the surface or near the surface the magnetic field distorts and leaks around the defect. By application of magnetic medium on the surface, the particles attract the area where flux leakage has occurred producing a visible indication of the defect. This indication can be evaluated by the operator any necessary measures are taken if any. Our techniques for magnetic particle inspection include: · Yoke · Bench (for headshot direct induction) · Coil shot · Prods · Central conductor ALPHA SONIX has skilled NDT personnel that have gained years of experience in performing MPI and are Level 2 and 3 qualified with ASNT. We provide the testing both on-site at our customers’ premises. When selecting ALPHA SONIX for your magnetic particle inspection (MPI) needs, you have an assurance that your maintenance schedules will be met and you will benefit from the expertise that our inspectors provide. Our reports will provide you with the necessary data to take preventive measures and will help in the management of assets.

...more

magnetic particle testing

2,000 Per test

Magnetic Particle Inspection (MPI) MAGNETIC PARTICLE INSPECTION Magnetic Particle Inspection (MPI) is an NDT method that can use magnetism to detect surface and subsurface discontinuities in ferromagnetic materials. MPI is generally used to determine parts fitness for use. It is a relatively easy and quick method that is widely used in various sectors such as automotive, oil and gas, aerospace, petroleum, power generation, etc. This method detects surface or subsurface discontinuities such as cracks, porosity, laps, seams, inclusions in ferromagnetic materials. One of the major advantages of this method is, it is a relatively fast method and gives an immediate indication on the surface. This method works by inducing the magnetic flux in the part to be tested. If any discontinuities or detect is present on the surface or near the surface the magnetic field distorts and leaks around the defect. By application of magnetic medium on the surface, the particles attract the area where flux leakage has occurred producing a visible indication of the defect. This indication can be evaluated by the operator any necessary measures are taken if any. Our techniques for magnetic particle inspection include: · Yoke · Bench (for headshot direct induction) · Coil shot · Prods · Central conductor ALPHA SONIX has skilled NDT personnel that have gained years of experience in performing MPI and are Level 2 and 3 qualified with ASNT. We provide the testing both on-site at our customers’ premises. When selecting ALPHA SONIX for your magnetic particle inspection (MPI) needs, you have an assurance that your maintenance schedules will be met and you will benefit from the expertise that our inspectors provide. Our reports will provide you with the necessary data to take preventive measures and will help in the management of assets.

...more

Magnetic Flux Leakage Test

90,000 Per Day

MAGNETIC FLUX LEAKAGE (MFL) This method provides the detection of corrosion, pitting, and erosion of pipes. Magnetic flux leakage (MFL) is an NDT method that is used to detect corrosion, pitting, or erosion in steel structures like pipes, floors, storage tanks. These can lead to loss of product and damage equipment hence it becomes necessary to inspect such parts to prevent the occurrence of such problems. MFL provides high-speed and reliable inspection of steel structures. Our highly qualified inspectors have gained years of experience in inspection and mapping structures. We use highly advanced MFL instruments to carry out inspection.This method uses permanent magnets or electromagnets to magnetize the part up to the saturation point and changes in the magnetic field are recorded. If there are any discontinuities the magnetic field leaks and then this leakage is analyzed to determine the location and nature of the defect both near the surface and far away. A map can be created using the data recorded which in turn helps in proper remedial action to be taken and for future planning and scheduling. Alpha Sonix is committed to providing Total Quality Assurance and ensuring inspections meet deadlines, standards, and are carried out safely and efficiently. While the schedule of maintenance is coordinated in such a way that minimizes disruption in business occurs while providing an optimum level of inspection within minimum possible time.

...more

Long Range Ultrasonic Testing Service

40,000 Per Day

Long Range Ultrasonic testing(LRUT)Ultrasonic testing over a long distance is a quick approach to check for corrosion in pipelines. The approach can screen up to 100 metres of pipeline in a single test, 50 metres in each direction. Because of the high production coverage rates compared to manual techniques, LRUT has been used to screen piping systems above ground, but it is still the only reliable technique for screening pipe systems underground or underwater, where access is often limited or very costly for manual contact techniques. The technology is still improving, and the number of apps that use this system has grown significantly.A wave maker device drives low frequency (20-100 kHz) ultrasonic waves longitudinally through the pipeline wall by placing a ring of transducers around the pipeline. The approach succeroblems. At the same time, this allows for thessfully identifies changes in the cross-section of the pipeline, allowing it to detect corrosion and other p use of welds and flanges as distance markers.Long Range Ultrasonic Testing (LRUT) is a technique that involves placing an array of probes in a belt that is circumferentially wrapped around the pipe being inspected. The system then generates ultrasonic guided waves that travel longitudinally down the length of the pipe. The distance covered by the ultrasonic waves is determined by a variety of elements including pipe coating, branch connections, fittings, and whether the pipe is above ground or buried. As a result, the system can inspect both ways from each inspection location, maximising production.Long-Range Ultrasonic Testing Benefits (LRUT) Traditional ultrasonic procedures are more than 100 times faster. On pipelines above ground, screening distances of up to 100 metres are possible. On subterranean pipelines, a screening distance of up to 10 metres is possible. Subsea scanning is a possibility. The pipe wall is completely covered in screening. For pipe integrity management programmes, a cost-effective option is available.

...moreBe first to Rate

Rate ThisOpening Hours