Wet Dust Collector

Wet type dust collector are designed to more efficient, cost effective control, all flammable and non-flammable metal dust contaminants generated from a variety of manufacturing and process applications . The wet type dust collector will help with compliance to local OSHA and NFPA regulations by drawing contaminants away from the operator’s breathing zone and reducing the flammability concerns with metals such as aluminium, titanium and magnesium. Direct drive blower and TEFC motor installed, auto water level control with low level shutoff and a factory pre-wired control panel. Wet type dust collector are working process for the capture of wettable and sinkable particles. This systems Five stage filtration system. First step goes to striking the turbulent water surface in the water tank section of the machine. Second process passing through a vertical water circulation. Third stage scrubbed though a water falls on cone walls, fourth step before the passing through a horizontal water circulation, finally buffeted through the moisture separator section before fan entry and exhaust out of the machine.Wet-type dust collector can handle up to 500cfm to 8000cfm and comes in six models . the power rating consumptions 1 hp to 15 hp are available. Blower is specially design a aluminium and steel impeller to create a high level vacuum and sucking capacity. quick to install and easy to operate. Special design dust collector hook up to 1 to 10 machines at a time. Blower design is 4 castors for manoeuvrability and total portability and permanently lubricated, fully enclosed, fan-cooled motors for continuous duty. High air velocity (CFM) design stands up to any competitive specifications. compact design to make a low noise level 60db to 80db only. Blower create a high and compactable static pressure value is 6.5 inch to 20 inches. An optional remote control is radio frequency so there is no need for line of sight to turn the machine on and off. Our systems meet or exceed government regulations for air quality and safety.

...more

Welding Fume extractor and Fume Extraction System

Apzem manufacturers welding smoke extractors, which are custom designed to meet the need of customers. Welding fume extractors are employed in extracting the welding smokes and fumes from variety of welding applications such as MIG welding, TIG welding, stick welding, cleanroom welding , production welding, stainless steel tank welding etc. Apzem welding smoke eaters are designed in such a way that they can be easily customized for example, Portable welding fume extractors can be easily moved around the work location. Apzem Welding Fume Extractor line of Products are designed to capture hazardous fumes generated while Welding. All our Portable Welding Fume Extractors are designed with heavy-duty industry grade casters and self-supportive source capture flexible arms with hoods to give the operator full flexibility in placing the unit in relation to their welding process. All our fume extraction system are equipped with high efficient filtration media which allows a recalculating air pattern that does not require exterior ducting or make-up air. Welding fumes are a complex mixture of metallic oxides, silicates and fluorides. and are formed during welding because a metal is heated above its boiling point and its vapors condense into very fine, particlesadditionally welding gases too added to fumes. Together they are very harmful to human and should be captured near source and filtered (see below table for common constituents of welding fumes. Application: Laser Marking Shielded Metal Arc Welding (SMAW,stick welding) Gas Metal Arc Welding (GMAW) or metal inert gas (MIG Welding) Flux Core Arc Welding (FCAW) Gas Tungsten Arc Welding (GTAW) or tungsten inert gas (TIG) welding Submerged Arc Welding (SAW)

...more

Welding Fume Extractor

Apzem manufacturers welding smoke extractors, which are custom designed to meet the need of customers. Welding fume extractors are employed in extracting the welding smokes and fumes from variety of welding applications such as MIG welding, TIG welding, stick welding, cleanroom welding , production welding, stainless steel tank welding etc. Apzem welding smoke eaters are designed in such a way that they can be easily customized for example, Portable welding fume extractors can be easily moved around the work location. Apzem Welding Fume Extractor line of Products are designed to capture hazardous fumes generated while Welding. All our Portable Welding Fume Extractors are designed with heavy-duty industry grade casters and self-supportive source capture flexible arms with hoods to give the operator full flexibility in placing the unit in relation to their welding process. All our fume extraction system are equipped with high efficient filtration media which allows a recalculating air pattern that does not require exterior ducting or make-up air. Welding fumes are a complex mixture of metallic oxides, silicates and fluorides. and are formed during welding because a metal is heated above its boiling point and its vapors condense into very fine, particlesadditionally welding gases too added to fumes. Together they are very harmful to human and should be captured near source and filtered (see below table for common constituents of welding fumes. We Provide complete Fume Extraction Solution with flexible arm, ducts, dampers etc... for capturing Welding, Soldering, chemical fumes and also fume control/gas abatement solutions with our line of Wet scrubbers & Dry scrubber Conforming to Local PCB Standards. and For enquiries or to know more feel free to contact us @ 9789066648 / 044-26580258 or email to sales@apzem.com Application: Laser Marking Shielded Metal Arc Welding (SMAW,stick welding) Gas Metal Arc Welding (GMAW) or metal inert gas (MIG Welding) Flux Core Arc Welding (FCAW) Gas Tungsten Arc Welding (GTAW) or tungsten inert gas (TIG) welding Submerged Arc Welding (SAW)

...more

Welding & Cutting Machine

We make available Welding & Cutting Machine procured from trusted manufacturers and vendors. The Welding & Cutting Machine Offered by us is designed as per the industrial parameters and is easy to install and operate. These precision engineered Welding & Cutting Machines are widely used in industries for cutting and welding with fineness and accuracy. These Welding & Cutting Machines are made available by us at industry leading prices. Demanded For : Consistent performanceHigh efficiencySturdy constructionHigh durability Features : Light beam design,good rigidity,light weight and tiny moving inertiaSmall cutting gap,no residuaY axis adopts double moters with double drivers.XYZ axis round raill,moving smoothly ,with high accuracy.(Option:squar raill)Excellent performance on cutting 3 D illuminated letters for advertising and channel letters on metal surface boardWorking together with other advertising machines,such as CNC Router and so on ,improving working efficiencyPoratable plasma welding machine Specifications Supply main voltage110-253 vLine Voltage50 -60 HzPower consumption kWup to 3.5Power supply dimensions cm38 x 14 x 19Torch weight kg0.9Power supply weight kg8.0Plasma flame temperature degC 8000Cut steel plate's thicknessup to 10 mmWelded steel plate's thicknessfrom 0. 3mmSteel sheet (at 2mm) cutting speedup to 7 mm/sWidth of sheet steel cut mm1.5 at mostWorking fluid consumption l/h0.25Torch filling operationmin 20-30Working Area1500*3000mm(59*102 inch)Cutting Tickness40A-0.5-10mm (120A)3-16mm (200A)3-25mmCutting Speed0-8000mm/minMoving Speed0-50000m/minPower8.5KW-10.5KWInput Voltage3 Phase 380VPower Frequency50HZFlies TransferUSB InterfaceArcUntouched Arc Striking

...more

water scrubber

Industrial process often generates large amount of exhausts gases, containing different gaseous air pollutants that are hazardous in nature and should be treated well before venting it to atmosphere as per pollution control Board norms. Apzem Wet scrubber system utilizes absorption techniques to separate pollutant acid gases from exhaust air. Apzem has been custom designing spray scrubber, Packed bed scrubber, Venturi scrubber, Horizontal type chromic acid scrubber for various customers across different industries. The selection and customization, is hugely depends on exhaust gas temperature, its constituents, corrosive nature, pollution loading, their absorption or adsorption nature, moisture contents etc.

...more

Walkin Fume Hood

Apzem Floor mounted walk-in series fumehoods are ergonomically designed for applications involving large apparatus and made from heavy gauge material for greater strength and robustness. And protects users from inhaling harmful gases and vapors released while experimenting & working at laboratories. All our fumehoods are finished with special coatings for greater corrosive resistance and equipped with lots of features boosting productivity and safety. Features: Construction:All our professional series fume hoods are of double walled construction made from heavy gauge Galvanized steel and are of robust in construction. Finish : All professional series Apzem fume hood are either powder coated or Epoxy coated for greater corrosive resistance. Sash opening : : The sash is designed to open vertically and is made of 6mm toughened glass or poly carbonate for greater strength and Longer life. It is balanced on the other side with a counter weight connected by rope & pulley or chain& sprocket (optional) arrangement to easily control the sash opening. Lighting: Vapor resistant light having light intensity greater than 1000 Lux for greater visibility and comfort. Others: All Apzem ductless fumehoods are pre-equipped with filter module having Pre filter, Fine, HEPA and Carbon filter that treats and filters out all dusts and VOCs. Baffle : Baffle is designed in such a way to remove easily for cleaning and to provide uniform air movements inside the fume hood. Ventilation : : As a standard feature all Apzem ductless fume hoods can be connected directly to building exhausts. As an optional feature we also provide our fume hoods with self contained suction chamber for greater control on airflow and works independently irrespective of building exhausts. Energy efficient: variable air flow control unit to maintain constant velocity inside the fume hood irrespective of sash openings. For greater safety and reduce energy consumption when sash is fully closed or fume hood is not in use for long time. Bypass openings: Bypass opening is provided to protect problems that arises when the sash is fully closed, like creating turbulence that can force contaminants into the room, slowing reactions etc.. Monitoring: All our Ductless fume hoods are preassembled with airflow monitor , that continuously monitors air flow velocities and alerts users when the velocity drops for greater safety. Locks: Maximum sash opening limit locks and a option for locking sash when its fully closed are provided on request. Customization: : We provide complete customization of all our fumehoods meeting your specific needs and applications.

Size : 1200 mm to 2000 mm wide

...more

WALK-IN FUME HOODS

Apzem Floor mounted walk-in series fumehoods are ergonomically designed for applications involving large apparatus and made from heavy gauge material for greater strength and robustness. And protects users from inhaling harmful gases and vapors released while experimenting & working at laboratories. All our fumehoods are finished with special coatings for greater corrosive resistance and equipped with lots of features boosting productivity and safety. Features: Construction:All our professional series fume hoods are of double walled construction made from heavy gauge Galvanized steel and are of robust in construction. Finish : All professional series Apzem fume hood are either powder coated or Epoxy coated for greater corrosive resistance. Sash opening : : The sash is designed to open vertically and is made of 6mm toughened glass or poly carbonate for greater strength and Longer life. It is balanced on the other side with a counter weight connected by rope & pulley or chain& sprocket (optional) arrangement to easily control the sash opening. Lighting: Vapor resistant light having light intensity greater than 1000 Lux for greater visibility and comfort. Others: All Apzem ductless fumehoods are pre-equipped with filter module having Pre filter, Fine, HEPA and Carbon filter that treats and filters out all dusts and VOCs. Baffle : Baffle is designed in such a way to remove easily for cleaning and to provide uniform air movements inside the fume hood. Ventilation : : As a standard feature all Apzem ductless fume hoods can be connected directly to building exhausts. As an optional feature we also provide our fume hoods with self contained suction chamber for greater control on airflow and works independently irrespective of building exhausts. Energy efficient: variable air flow control unit to maintain constant velocity inside the fume hood irrespective of sash openings. For greater safety and reduce energy consumption when sash is fully closed or fume hood is not in use for long time. Bypass openings: Bypass opening is provided to protect problems that arises when the sash is fully closed, like creating turbulence that can force contaminants into the room, slowing reactions etc.. Monitoring: All our Ductless fume hoods are preassembled with airflow monitor , that continuously monitors air flow velocities and alerts users when the velocity drops for greater safety. Locks: Maximum sash opening limit locks and a option for locking sash when its fully closed are provided on request. Customization: : We provide complete customization of all our fumehoods meeting your specific needs and applications.

...more

VOC Scrubber Dry Scrubber

Apzem VOC Scrubber are custom designed to capture and treat VOCs ( Volatile organic compounds) generated in industrial process. VOCs are organic compounds having very low boiling point, and becomes vapors at atmospheric condition. Not all VOCs are toxic but majority of them are toxic and should be controlled within the limits per PCB and EPA Norms. Toxic VOCs comes under the classification of HAP ( Hazardous air pollutants). For a detailed list of Toxic VOCs refer below table. Some VOCs have higher molecular weight and easily gets trapped / adsorbed in adsorption media. For those VOCs Apzem dry VOC scrubber is an economical option to capture and control. In some cases the cost of VOCs would be high and recovery of such VOCs using Apzem Regenerative type Dry scrubber yields high return on Investment. But some of the VOCs will not get trapped in adsorption media and are highly flammable. In that cases installation of Thermal Oxidizers or Catalytic oxidizers would be a better option. In some cases mere condensing of VOCs itself helps capturing it. A simple spray scrubber would be sufficient in that cases. Effective and efficient capturing and controlling of VOCs needs a thorough understanding of the process, types and quantity of VOCs present and properties of it, temperature and presence of other components and dusts. Apzem had a strong team of consultants and engineers having deep knowledge in design and commissioning of VOC scrubber system across various industries helps us to design a better and economical solution to your VOCs and other air pollution control needs. Feel free to contact us to assist you in selecting efficient and economical scrubber system to your specific process and pollution control needs. Click here for Complete list of Toxic VOCs classified under hazardous Air Pollutants by EPA and PCB Application Industries: Adhesives, Aluminum fabrication, Asphalt plants, Coating operations, Chemical plants, Drying ovens, Food processing, Furniture manufacture, Foundries, Oil and petrochemical, Painting operations, Plastics, Polymers, Printing, Pulp and paper manufacture, Metals fabrication, Resins, Rubber products, Pharmaceuticals, Sealant, Smoke houses, Textile finishing, Tire operations, Wastewater treatment, and

...more

VOC Scrubber

Apzem Bio Scrubber for VOCs control are environmental friendly scrubber that works on the principle of anaerobic digestion of organic VOCs by bacteria. Some VOCs creates bad odors and organic nature and generated in industrial process and in wastewater treatment plants and are readily digested by bacteria grown in a constrained environment with proper supply of enzymes and nutrients. Bio scrubber or Bio-filter is a most economical solution for effective treatment of some of organic components and lasts for 10 to 20 years without much maintenance costs, but it has certain limitations like it requires large floor space, cannot treat high temperature exhaust gas as well as presence of other components and dusts. In some applications, installing a bio-scrubber as secondary scrubber in line with cyclone / bag filter dust collector and wet scrubber will serves more effectively. Other options for treating small quantity VOCs adsorption type Apzem dry scrubber is highly recommended. Apzem had a strong team of consultants and engineers having deep knowledge in design and commissioning of Bioscrubbers and other industrial air pollution control equipments , hoods, ducting. And are looking forward to provide you end to end , complete turnkey solutions to your odour & Air pollution control needs. Application Industries: Wastewater treatmentAadhesives, aluminum fabrication, Asphalt plants, Coating operations, Chemical plants, Drying ovens, Food processing, Furniture manufacture, Foundries, Oil and petrochemical, Wood products manufacture Painting operations, Plastics, Polymers, Printing, Pulp and paper manufacture, Tire operations, Resins, Rubber products, Pharmaceuticals, Sealant, Smoke houses, Textile finishing,

...more

Venturi Scrubber Wet scrubber

Apzem Venturi Wet Scrubber are custom designed to capture smaller dust particles, VOCs, chemical fumes, and other water / chemically soluble fumes and Vapors generated in industrial process. Venturi scrubber is a kind of wet scrubber and is of high efficient in comparison to other wet scrubbers at a higher pressure drop. Venturi scrubber works on the principle of absorption technology and venturi effect, where the pollutants gas and scrubbing liquid / water is made to pass through a confined throat where both comes in contact so closely at high velocity forming large number of droplets, there by creating large area for the particles to get absorbed to liquid droplets. The sizing of scrubber, Throat design, selection of scrubber solution, Material and inner lining is critical in designing Venturi scrubber for a particular application. Apzem had a strong team of consultants and engineers having deep knowledge in design and commissioning of Venturi scrubber across various industries for different applications. contact us to assist you in selecting efficient and economical scrubber to your specific process and pollution control needs. Materials of Construction: Fiberglass reinforced plastic (FRP) MS, M.S with FRP Lined , M.S with Epoxy coated PVC , CPVC Polypropylene SS 304 or 316 Air/Gas Pollutants Removed: Particles upto 1 microns, Acid gasses, VOC etc.. Application: Chemical industries Pulp and paper industries Petrochemical industries Steel making Corn Processing Facilities, Food Manufacturing, Pharmaceutical industries Fertilizer production and processing industries Machining and Grinding exhaust, Fiberglass & Composite Industries, Utility Boilers, Foundries and Metal Finishing Operations.

Efficiency : upto 99.99% capturing efficiency

...more

Venturi Scrubber

Apzem Venturi Wet Scrubber are custom designed to capture smaller dust particles, VOCs, chemical fumes, and other water / chemically soluble fumes and Vapors generated in industrial process. Venturi scrubber is a kind of wet scrubber and is of high efficient in comparison to other wet scrubbers at a higher pressure drop. Venturi scrubber works on the principle of absorption technology and venturi effect, where the pollutants gas and scrubbing liquid / water is made to pass through a confined throat where both comes in contact so closely at high velocity forming large number of droplets, there by creating large area for the particles to get absorbed to liquid droplets. The sizing of scrubber, Throat design, selection of scrubber solution, Material and inner lining is critical in designing Venturi scrubber for a particular application. Apzem had a strong team of consultants and engineers having deep knowledge in design and commissioning of Venturi scrubber across various industries for different applications. contact us to assist you in selecting efficient and economical scrubber to your specific process and pollution control needs. Materials of Construction: Fiberglass reinforced plastic (FRP) MS, M.S with FRP Lined , M.S with Epoxy coated PVC , CPVC Polypropylene SS 304 or 316 Air/Gas Pollutants Removed: Particles upto 1 microns, Acid gasses, VOC etc.. Application: Chemical industries Pulp and paper industries Petrochemical industries Steel making Corn Processing Facilities, Food Manufacturing, Pharmaceutical industries Fertilizer production and processing industries Machining and Grinding exhaust, Fiberglass & Composite Industries, Utility Boilers, Foundries and Metal Finishing Operations.

...more

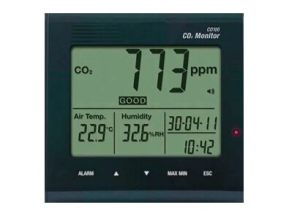

Ventilation Survey system

In any Industrial environment the quality of air inside the premises should be safe and comfortable to its workers to be more productive. The ventilation system should be properly designed and periodic checks and servicing should be carried for effective functioning of it and is necessary to maintain a safe, Healthy & Productive environment inside the Factory premises.In any Industrial environment the quality of air inside the premises should be safe and comfortable to its workers to be more productive. The ventilation system should be properly designed and periodic checks and servicing should be carried for effective functioning of it and is necessary to maintain a safe, Healthy & Productive environment inside the Factory premises.The presence of high temperature causes heat stress, High Relative Humidity makes to feel sick. Presence of Harmful air pollutants affects adversely affects human health and increases no of sick leaves. It all occurs when Local ventilation system, Air cleaners, HVAC system, Man cooling system etc fails to function properly, or no such system is installed.Ventilation survey & Air quality audit provides data's relating to presence of air pollutants & its sources, presence of heat generating sources, air velocity, relative humidity, presence of fumes, dusts and other particle matters and pollutants classified by governing bodies. It also gives input to effectively design and install different Ventilation and air cleaning equipments to make it a healthy and productive environment.Apzem had a strong knowledge in Industrial air pollution, production process, Heating & Ventilation , Occupation safety standards and provide below list of Services wide variety of Industries. Our Services: Hood Face velocity measurements (fpm) Air duct velocity measurements (fpm) Air volume flow measurements (cfm) Temperature & RH Measurements, Stack emission monitoring. Pressure drop measurements Effectiveness of Air pollution control equipments, Design change recommendations.

...more

Ventilated Cabinets

Our clients can avail from us Ventilated Cabinets that are designed to perfection under the strict vigil of our professionals. These APZEM VSC-XX series ventilated storage cabinets are primarily manufactured to store specimen containers & fluid containers like formalin and chloroform. The ventilation is designed in such a way that helps in removing chemical odors, aerosols away from personnel.

...more

Two Stage Dust Collector

The two-stage dust collector all the features in a compact size. A side from the cleaner operation of a two-stage system. Dust collector with 2- stage filtration system. Central inlet with velocity reducer. Fully automatic filter cleaning. Can easily be equipped with a great variety of filter materials, bins, emptying systems, explosion relief panels etc. dust collector with automatic cleaning, individual filter bags are overlaid on a metal cage. The dirty air enters the Bag house and is forced through the filter bags after which the clean air exits. A timer signals a solenoid valve to start the cleaning when it detects a drop in performance due to build up on the filter or the cleaning cycle is run on a regular periodic basis. Cleaning the filter is done by short bursts of compressed air being fired down through the filter bags. This air burst causes the dust cake to disintegrate and fall so it can be collected. Determining the filter material is an important part of bag house design, as it determines the life and effectiveness of the filter bag. The type of fabric used depends on many factors including volume of dust, size of dust, moisture content etc.Two stage dust collector is high level performance carry to a low to high load of motor power 1 hp to 10 hp. It is a handle up to 500cfm-8000cfm airflow rating. 14” inch steel impeller create a high vacuum to make a great sucking performance on the blower. Two stage dust collector design a two type of style like a bag and canister used in high efficiency up to 5 micron. It is a neat and humble so don’t make a nuisance noise in work plant. It is noise level 69db-80db level. Blower create a high and compactable static pressure value is 6.5 inch to 20 inches. High air velocity (CFM) design stands up to any competitive specifications. A TEFC enclosure on a motor means "Totally Enclosed, Fan Cooled".This motor is probably the most commonly used motor in ordinary industrial environments. It costs only a few dollars more than the open motor, yet offers good protection against common hazards. Dust collector have a collection bag capacity up to 450 gallon capacity so lots of dust particles stored in a tank not pollute the atmosphere and work plant. An optional remote control is radio frequency so there is no need for line of sight to turn the machine on and off.

Power : from 2 HP to 10 HP

...more

Table top Chemical Fume Hoods

Apzem basic table top series fume hoods are ergonomically designed, simplest and most affordable fume hood made of high grade galvanized steel sheets and epoxy coated interior that better fits for small labs and single users, providing maximum protection to users from inhaling harmful gases and vapors released while experimenting & working at laboratories. All our fumehoods are finished with special coatings for greater corrosive resistance and equipped with lots of features boosting productivity and safe. Features: Construction: All our Basic series fume hoods are of single wall / double walled construction and made from heavy gauge Galvanized steel and are of robust in construction. Finish : All Apzem table top fume hoods are either powder coated or Epoxy coated for greater corrosive resistance. Sash opening : The sash is designed to open vertically and is made of 6mm toughened glass or poly carbonate for greater strength and Longer life. It is balanced on the other side with a counter weight connected by rope & pulley arrangement to easily control the sash opening. Lighting: Vapor resistant light having light intensity greater than 800 Lux for greater visibility and comfort. Others: All professional series Apzem fume hood comes with a water and gas pipe options, and a pair of power sockets. Baffle : Baffle is designed in such a way to remove easily for cleaning and to provide uniform air movements inside the fume hood. Ventilation : As a standard feature all Apzem fume hoods can be connected directly to building exhausts. As an optional feature we also provide our fume hoods with self contained suction chamber for greater control on airflow and works independently irrespective of building exhausts. Energy efficient: Variable air flow control unit to maintain constant velocity inside the fume hood irrespective of sash openings. For greater safety and reduce energy consumption when sash is fully closed or fume hood is not in use for long time. Bypass openings: Bypass opening is provided to protect problems that arises when the sash is fully closed, like creating turbulence that can force contaminants into the room, slowing reactions etc.. Monitoring: Optionally our fume hoods are preassembled with airflow monitor , that continuously monitors air flow velocities and alerts users when the velocity drops for greater user safety. Customization: We provide complete customization of all our fumehoods meeting your specific needs and applications.Apzem is a well know manufacturers and supplier of wide range of Fume Hood , which are used to control exposure to hazardous or noxious chemical fumes across varied industries, Hospitals and research Institutions. We also provide custom designed fume hoods meeting specific needs and labs.

...more

Table Top-AT Series

APZEM table top grossing station were designed to provide affordable workstation for single user and for small labs. The system provides optimum suction capacity with air moving inwards over entire work area removing all formalin and other harmful fumes away from user while grossing. Specifications CE Certified. All Stainless steel Construction made of 18 Gauge (1.2mm) SS 304 Inbuilt ventilation system capable of removing all formalin fumes from work top and from Technicians breathing zone Sink Cold water Faucet Back Draft fume Removal system. Removable perforated worktop Powerful LED Lighting C-Fold paper towel Holder. Polyethylene Dissecting Board for Dissecting and for Photography. Magnetic Tool holder Cleanable Pre Filter to remove fine particles. Standard Dimension : 750mm(W) X 1100mm (H) X 900mm (L) Shelf for storing containers. Hand rinsing assembly Medium capacity 0.45 HP waste disposal unit. Transparent Acrylic air deflector panel. 40mm height adjustable leg for accurate leveling of work surface. Provision for mounting splash shield and adjustable camera holder.

...more

suction hood

Fumes are generated in various industry process like Laser cutting, Laser Marking, Plasma cutting, Welding, Chemical Laboratory, and also in chemical storage applications. These fumes hazardous to human health and should be effectively removed, Filtered and then passed to atmosphere. Fume Extractors or Fume Extraction System is a device or a set of arrangements to collect fumes from various processes via suction hood, transport it to filtering unit via ducts, and is filtered there and then passed to atmosphere.

...more

Steel Bar Bending Machine

With the supply of Steel Bar Bending Machine, we cater to the demands of Construction industry. These Steel Bar Bending Machines are suitable for bending of Steel bars with precision. We offer premium Steel Bar Bending Machine procured from advanced manufacturers. Owing to accurate performance and long usable life, the Steel Bar Bending Machine is highly demanded. Demanded For : Easy operational featuresPowerful performancePrecise cutting at desired angleRobust construction Specifications Bending Φ 4-40mmRotate Speed of the Principal Axis 8~12r/minMotorPower : 3KWVoltage :380VFrequency : 50HZInput : three phase

...more

ss scrubbers

Industrial process often generates large amount of exhausts gases, containing different gaseous air pollutants that are hazardous in nature and should be treated well before venting it to atmosphere as per pollution control Board norms. Apzem Wet scrubber system utilizes absorption techniques to separate pollutant acid gases from exhaust air. Apzem has been custom designing spray scrubber, Packed bed scrubber, Venturi scrubber, Horizontal type chromic acid scrubber for various customers across different industries. The selection and customization, is hugely depends on exhaust gas temperature, its constituent

...more

SS Duct

Industrial ducting made of stainless steel (SS202, SS304, SS316 etc) had very wide application in corrosive environment, as well as in food, medical and clean room industries. SS ducts can be made as spiral ducts as well as rolled heavy gauge ducts. SS ducts have greater strength, longer life, and high corrosion resistance but its 3 to 5 times more costlier than MS ducts. Using SS ducts in a normal environment where MS ducts itself efficiently serves the requirements would not be a wise option. Also using MS ducts in place where SS ducts is required would also is not a wise option. Careful selection and designing of ducting will save lots of money and productivity in long run. We could also use FRP ducts, GI ducts, Spiral ducts, Aluminium ducts, Flexible ducts along with SS ducts together forming complete ducting system based on applications. Since air being a compressible fluid, the ducting should be properly designed for maximum efficiency with minimum losses. If the ducts , bends, branches etc..are not properly designed considering proper bend radius or process parameters like dust loads, moisture content, Industrial dust carrying velocities etc..it wont serves its purpose. Powder accumulation on bends occurs, more velocity and pressure would have been lost as friction. Improperly designed ducting system will have more friction loses, and increases blower power consumption as well as power bills. Properly designed ducting system consumes less power and gives more cost savings in long term. Application Industries: Air pollution control equipments HVAC ducting Powder transportation industry Cement plants Wastewater Treatment Plants Petrochemical Plants Laboratory Exhaust Glass and Metal Foundries Clean Rooms Plating & Metal Finishing Facilities Pulp and Paper Industry Marine Exhaust Systems Food Processing Facilities Apzem had a strong team of engineers having deep knowledge in various industrial processes, duct design, international ducting standards (SMACNA, AMCA etc..) . We are happy to assist you in selecting, designing ducting for your process needs.

...more

Spray Scrubber

Spray scrubber can be used to capture particulate matter of size 2 microns and large particulates. It can also remove gaseous pollutants. Apzem is a leading manufacturer of spray tower scrubber in India. Apzem’s wet spray scrubbers incorporates standard design features and so it is extremely compact and can be easily customized based on the requirements. Apzem Spray Tower Scrubber is the simplest of wet scrubber and are custom designed to capture dust particles, VOCs, chemical fumes, and other water / chemically soluble fumes and Vapors generated in industrial process. Spray tower scrubber is of low efficiency in comparison to other wet scrubbers at a lower pressure drop. Apzem had a strong team of consultants and engineers having deep knowledge in design and commissioning of wet scrubber across various industries for different applications. contact us to assist you in selecting efficient and economical scrubber to your specific process and pollution control needs. The dust laden impure air enters through the inlet. Here hydraulically atomized droplets of scrubbing liquid collide with the incoming gas and impinge with the particulates. Here some of the water soluble pollutants gets absorbed by spray droplets. The fierce scrubbing done here eliminates and stops the escaping of untreated contaminants. In the final section of the scrubber the particulate matter gets collected. When it enters the cyclonic section the remaining particulates that escaped gets collected due to the centrifugal action and most of the droplets from the gas. The dust particulates are collected in the sump. The clean gas exits through the top of the scrubbing unit. Air/Gas Pollutants Removed: Particles upto 1 microns, Acid gasses, VOCs etc.. Application: Chemical industries Pulp and paper industries Petrochemical industries Steel making Corn Processing Facilities, Food Manufacturing, Pharmaceutical industries Fertilizer production and processing industries Machining and Grinding exhaust, Fiberglass & Composite Industries, Utility Boilers, Foundries and Metal Finishing Operations.

...more

Spiral ducts and Ducting

Spiral ducts are rolled spirally using a GI coil by a special machines, The spiral ducts are easy to manufacture, and are widely used in various industries. Specially in HVAC industries. Spiral ducts are normally made of thinner materials, and light weight in nature and the spiral joining formed over the surface adds more strength to it. Since this ducts are lighter , doesnt require heavy supports and can be easily hanged from roof / wall. Spiral ducts has its own limitations like thicker spiral ducts cannot be made easily and also loses is also bit higher in comparison to other ducts having smoother inner surface. Since air being a compressible fluid, the ducting should be properly designed for maximum efficiency with minimum losses. If the ducts , bends, branches etc..are not properly designed considering proper bend radius or process parameters like dust loads, moisture content, dust carrying velocities etc..it wont serves its purpose. Powder accumulation on bends occurs, more velocity and pressure would have been lost as friction. Improperly designed ducting system will have more friction loses, and increases blower power consumption as well as power bills. Properly designed ducting system consumes less power and gives more cost savings in long term. Application Industries: Air pollution control equipments HVAC ducting Powder transportation industry Cement plants Wastewater Treatment Plants Petrochemical Plants Laboratory Exhaust,Glass and Metal Foundries Clean Rooms Plating & Metal Finishing Facilities Pulp and Paper Industry,Marine Exhaust Systems,Food Processing Facilities Apzem had a strong team of engineers having deep knowledge in various industrial processes, duct design, international ducting standards (SMACNA, AMCA etc..) . We are happy to assist you in selecting, designing ducting for your process needs.

...more

spiral ducts

Industrial ducting made of stainless steel (SS202, SS304, SS316 etc) had very wide application in corrosive environment, as well as in food, medical and clean room industries. SS ducts can be made as spiral ducts as well as rolled heavy gauge ducts. SS ducts have greater strength, longer life, and high corrosion resistance but its 3 to 5 times more costlier than MS ducts. Using SS ducts in a normal environment where MS ducts itself efficiently serves the requirements would not be a wise option. Also using MS ducts in place where SS ducts is required would also is not a wise option. Careful selection and designing of ducting will save lots of money and productivity in long run. We could also use FRP ducts, GI ducts, Spiral ducts, Aluminium ducts, Flexible ducts along with SS ducts together forming complete ducting system based on applications. Since air being a compressible fluid, the ducting should be properly designed for maximum efficiency with minimum losses. If the ducts , bends, branches etc..are not properly designed considering proper bend radius or process parameters like dust loads, moisture content, Industrial dust carrying velocities etc..it wont serves its purpose. Powder accumulation on bends occurs, more velocity and pressure would have been lost as friction. Improperly designed ducting system will have more friction loses, and increases blower power consumption as well as power bills. Properly designed ducting system consumes less power and gives more cost savings in long term. Application Industries: Air pollution control equipments HVAC ducting Powder transportation industry Cement plants Wastewater Treatment Plants Petrochemical Plants Laboratory Exhaust Glass and Metal Foundries Clean Rooms Plating & Metal Finishing Facilities Pulp and Paper Industry Marine Exhaust Systems Food Processing Facilities Apzem had a strong team of engineers having deep knowledge in various industrial processes, duct design, international ducting standards (SMACNA, AMCA etc..) . We are happy to assist you in selecting, designing ducting for your process needs.

...more

Spiral Duct Machine

Spiral ducts are rolled spirally using a GI coil by a special machines, The spiral ducts are easy to manufacture, and are widely used in various industries. Specially in HVAC industries. Spiral ducts are normally made of thinner materials, and light weight in nature and the spiral joining formed over the surface adds more strength to it. Since this ducts are lighter , doesnt require heavy supports and can be easily hanged from roof wall. Spiral ducts has its own limitations like thicker spiral ducts cannot be made easily and also loses is also bit higher in comparison to other ducts having smoother inner surface.

...moreBe first to Rate

Rate ThisOpening Hours