Universal Testing Machine

“A universal testing machine is used to test the tensile stress and compressive strength of materials. It is named after the fact that it can perform many standard tensile and compression tests on materials, components, and structures.” This is very true, but perhaps overly simplistic. We’ll try to explain some more capabilities of these machines in this post. Before we begin, we need to discuss terminology. We’re amazed at the variety of terms in the industry that are used to refer to a UTM. Most common are “tensile tester”, “compression tester” and “bend tester”. There are also UTM’s that have been stripped of capabilities or marketed to a specific sector which have led to the development of specialized names such as “texture analyzer” for food, “top load compression tester” for packaging and pipe, and “peel tester” for adhesives, tapes, and labels. Today, a UTM can perform all of these tests and more. A UTM is a great multi-purpose instrument for an R&D lab or QC department. In layman’s terms, here are a few examples of what a UTM can do: Features Loading Accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for easy of operation. Robust staining frame of an extremely rigid construction. Safe operation ensured be means of safety devices. Fully enclosed and protected pendulum.

...more

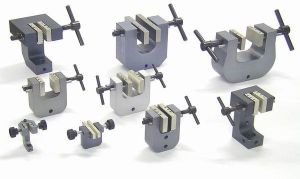

Testing Machines Grip Set

The Mechanical Vise Grips are designed for low, medium and high capacity applications. The Vise Grips are ideal for general tensile strength testing of paper, plastics, fine metals, textiles and other sheet materials. Various grip insert widths are available. Features Loading Accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for easy of operation. Robust staining frame of an extremely rigid construction. Safe operation ensured be means of safety devices. Fully enclosed and protected pendulum.

...more

Tensile Testing Machine

Tensile strength is the stress at which a material breaks or permanently deforms. There are three definitions of tensile strength, yield strength, ultimate strength and breaking strength. Tensile tests are usually carded out on wire, strip or machined samples with either circular or rectangular cross section. Test pieces are screwed into or gripped in jaws and stretched by moving the grips apart at a constant rate while measuring the load and the grip separation. This data is plotted as load vs extension and then converted to engineering stress (load/original area) vs engineering strain (fractional change in length over the test section assuming the deformation is uniform). In special circumstances, the actual stress and strain may be calculated if the true cross section is measured during the test. Features Loading Accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for easy of operation. Robust staining frame of an extremely rigid construction. Safe operation ensured be means of safety devices. Fully enclosed and protected pendulum.

...more

Production Machinery Automation

As the global manufacturing environment changes in a rapid and dramatic way, machinery will need to be designed to meet the demands of the manufacturing community. Machines will need to be re-designed to support an increasingly greater variety and number of sensors that allow for interrogation, fault detection, failure prediction, and more performance analysis. Evaluation of machine performance is changing, as customers and machine builders begin monitoring their machinery to determine optimal running conditions. This has become the predominant business case for developing an ecosystem built on the Industrial Internet of Things (IIoT) in the industrial machinery market. Features Loading Accuracy as high as + 1% Straining at variable speeds to suit a wide range of materials. Continuous roll autographic recorder supplied as standard to enable study of the behavior of materials Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen. High reading accuracy due to large size and design of dial. Wide range of standard and special accessories, including load stabilizer. Easy change from plain to threaded and screwed specimens. Large effective clearance between columns enables testing of standards specimens as well as structures. Simple controls for easy of operation. Robust staining frame of an extremely rigid construction. Safe operation ensured be means of safety devices. Fully enclosed and protected pendulum.

...more

foam slitting machine

Foam slitting machine of circular foam cutting machine which is performance efficient and delivers reliable results. We have a team of experts who handle our quality department and ensure that our products meet both Indian as well as international quality standards. Our circular foam cutting machine is equipped with the following systems:

...more

Foam Cutting Machine

Foam Cutting Machines are designed to deliver high yield of desired thickness PU foam sheets. The basic structure of circular foam cutting machine is constructed of a stationary cutting unit and a rotating circular table top. The raw foam produced as blocks needs to be processed into sheets of desired thicknesses. The yield of a continuous foam making plant is generally high and requires a very efficient, high capacity machine to efficiently convert the foam blocks into sheets of various desired thicknesses. For this kind of processing demands, the circular cutting machine has been found to be extremely useful. We are known manufacturers of circular foam cutting machine which is performance efficient and delivers reliable results. We have a team of experts who handle our quality department and ensure that our products meet both Indian as well as international quality standards. Our circular foam cutting machine is equipped with the following systems: Features Blade breakage sensor and running blade warning light Servo motor that controls the up/down movement of main blade frame Vacuum system: the vacuum holds the foam block & stabilizes them on the table. Programmable controlled cutting procedure and touch screen display Table driving system that controls rubber roller and an AC electric motor with variable ac drive Blade angle adjustment is done by electrically controlled system on main control panel. Cast PU wheels (elastomers) for smooth & noise-free running of circular table. Power required to run the machine is 20 hp and it utilizes 3 phase power and may be supplied for 50 or 60 Hz operation

...more

continuous foaming machine

Continuous foaming machine is performance efficient and delivers reliable results. We have a team of experts who handle our quality department and ensure that our products meet both Indian as well as international quality standards. Our circular foam cutting machine is equipped with the following systems:

...more

circular foam cutting machine

Circular foam cutting machine which is performance efficient and delivers reliable results. We have a team of experts who handle our quality department and ensure that our products meet both Indian as well as international quality standards. Our circular foam cutting machine is equipped with the following systems:

...more

hydrology instruments

Piezometer Water Level recorder (DWLR) Shaft encoder type digital automatic water level recorder Radar water level transmitter and recorder Ultrasound water level transmitter Water level switches Servicing of Dam instruments

...moreBe first to Rate

Rate ThisOpening Hours