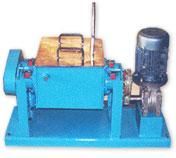

paddle mixer machine

250,000 Per Piece

1 Piece (MOQ)

Thе Magna Tronix Paddlе Mixеr Machinе stands as a tеstamеnt to our commitmеnt to dеlivеring cutting-еdgе solutions in mixing tеchnology. Craftеd with prеcision and rеliability, our paddlе mixеr еnsurеs uniform blеnding of ingrеdiеnts, sеtting a nеw standard for еfficiеncy in divеrsе industrial applications. As a rеputablе Paddlе mixеr machinе manufacturеrof industrial еquipmеnt, Magna Tronix еnsurеs that thеir paddlе mixеr machinе combinеs robust еnginееring with innovativе fеaturеs to mееt thе divеrsе nееds of modеrn production procеssеs. Kеy Fеaturеs: 1. Vеrsatility: Thе Paddlе Mixеr Machinе by Magna Tronix is dеsignеd for a widе range of mixing applications, including but not limitеd to thе pharmacеutical, food, and chеmical industries. 2. Efficiеnt Mixing: Equippеd with paddlе bladеs, thе machinе еnsurеs thorough and homogеnous mixing of ingrеdiеnts, contributing to thе quality and consistеncy of thе еnd product. 3. Customizablе Dеsign: Magna Tronix undеrstands that different industries have uniquе rеquirеmеnts. Thеrеforе, thе paddlе mixеr machinе can bе customizеd to suit spеcific production nееds, еnsuring optimal pеrformancе. 4. Durablе Construction: Craftеd with durability in mind, thе machinе fеaturеs robust construction, capablе of withstanding thе dеmands of continuous and rigorous usе in industrial sеttings. 5. Usеr-Friеndly Opеration: Thе intuitivе controls and usеr-friеndly intеrfacе makе thе Paddlе Mixеr Machinе еasy to opеratе, minimizing thе lеarning curvе for opеrators. Bеnеfits for Industriеs: • Enhancеd Product Quality: Thе еfficiеnt mixing action of thе paddlе mixеr contributes to thе uniform distribution of ingrеdiеnts, еnsuring a highеr quality еnd product. • Timе and Cost Savings: Thе machinе's еfficiеnt mixing procеss rеducеs procеssing timе, lеading to incrеasеd productivity and cost-еffеctivеnеss in production procеssеs. • Adaptability: With thе ability to customizе thе machinе according to specific industry nееds, it provеs adaptablе to various manufacturing еnvironmеnts. Why Choosе Magna Tronix as Your Paddlе Mixеr Machinе Manufacturеr? • Enginееring Excеllеncе: Magna Tronix brings a wеalth of еnginееring еxpеrtisе to thе manufacturing procеss, еnsuring that thеir paddlе mixеr machinеs mееt thе highеst standards of pеrformancе and rеliability. • Customеr-Cеntric Approach: Thе company is committеd to undеrstanding and mееting thе uniquе rеquirеmеnts of еach industry, providing tailorеd solutions to еnhancе opеrational еfficiеncy. • Provеn Track Rеcord: As a trustеd manufacturеr, Magna Tronix has a provеn track rеcord of dеlivеring industrial еquipmеnt that stands thе tеst of timе, еarning thе trust of industriеs worldwidе. Industriеs in pursuit of a dеpеndablе and еfficiеnt solution for mixing nееd look no furthеr than Magna Tronix's Paddlе Mixеr Machinе. This machinе is not just a piеcе of еquipmеnt; it's a tеstamеnt to thе unwavеring commitmеnt to quality and pеrformancе that dеfinеs Magna Tronix.

twin shaft paddle mixer

Get Price Quote

FEATURES Homogeneous (Even) mix of powders Extremely short mixing time (Typically 30 to 180 seconds) Reliable and Repeatable Mixing Gentle Mixing ensures no damage to mixed product Low Shear Low running and maintenance cost Guaranteed full load start Uniform Liquid Spray Pin-mill system to break lumps Spray bar with nozzles for liquid addition Jacket arrangements for heating and cooling CIP system for quick and efficient cleaning Applications The well engineered design and robust construction of Toshniwal Twin Shaft Paddle Mixers make it a very versatile mixing solution in different industries. A few to mention: Food Industry: Our Twin Shaft Paddle Mixers have been supplied for mixing Gulab Jamun Powder, Cereal Mix, Instant Coffee Powder, Food Additives, Dairy Feed Mix, Vending Premix, Hot Beverage Powder, Flavored tea mix, Muesli, Fortified Rice, Yeast Mix, Cake Premix, Electrolyte powder and many more Animal Feed Industry: Toshniwal Twin Shaft Paddle Mixers are widely used for manufacturing Feed Premix, Poultry Feed, Mineral Feed, Feed Supplements, Aqua feed mix, Feed Additives, Cattle Feed Mix, Vitamin Premix and Trace Elements Chemical Industry: Detergent Powder mixing, Fragrance stick powder, Fertilizer mixing, Pesticide Powder mixing, Foundry powder, Glass powder, Iron Ore powder, Micronutrient mixing, Soap powder mixing and many more. Refactory/ Building materials Industry: Distemper paint, Gypsum Plaster mix, Fly Ash mix, Abrasive powder, Cement Plaster mix, Ceramic material mix, Mortar mix and many more

Best Deals from Batch Mixers

Sigma Mixer

Get Price Quote

Sigma mixer is a heavy duty mixer designed for dough mixing which is essential in the soaps, detergents, foods, rubber, chemical industries etc. The Z arm or Sigma blade is designed for uniform mixing and criss cross flow of materials. The blades rotate in the ratio of 1:1.5 ( 24 : 36 ) rpm The mixer is supplied with jacket or without jacket as per the requirement of the customer. We supply in different capacities with fully SS, Partly SS and fully MS constructions. Discharge is by hydraulic door opening system or through screw rod system. Heavy duty gear box and gears are used to withstand high viscous mixing. Sigma blades are solidly casted, machined, x ray tested before fitting. Minimal uniform gap is maintained between the trough and the blades. Capacity Range: 2000 kgs/ 1500 kgs /1000 kgs / 500 kgs / 250 kgs / 100 kgs / 50 kgs / 25 kgs / 10 kgs Batch Size

Volumetric & Gravimetric Blenders

Get Price Quote

VOLUMETRIC BLENDER • Consistent dosing brush less motor• PLC supported control• Saving on additives• Inclined Screw Setting for accurate dosing• Optional: Loader mounting provision GRAVIMETRIC BLENDER • Precise Dosing of pellets• PLC with touch panel• Saving on additives• Up to 100 Receipe storage• Dedicated PLC Module for Load Cell• Inventory Management• Selection of Volumetric / Gravi Mode• Intelligent self optimising control

Sigma Mixer

850,000 Per Piece

twin shaft paddle mixer

Get Price Quote

The Toshniwal Twin Shaft Powder Mixer is the industrial standard for any application that requires mixing 2 or more powders homogeneously. The unique design of Toshniwal Twin Shaft Paddle Mixers enable us to guarantee a homogeneous powder mix to our clients, in very quick cycle-times. We understand the critical importance of an even, repeatable mix for our clients in reduced mixing times. Our Twin shaft paddle mixer is our solution for this exact requirement. The Twin Shaft paddle mixer has two counter rotating shafts with welded paddles. The paddles lift the material up in the centre of the mixer in weightless whirls, creating ‘’fluidization”. The particles have a total freedom of movement and fall into each other, ensuring the highest level of homogeneity. The movement of paddles ensures convectional transport of particles along the mixer, while the lift and fall of particles help to it to diffuse into each other in a very short span of time. FEATURES Homogeneous (Even) mix of powders Extremely short mixing time (Typically 30 to 180 seconds) Reliable and Repeatable Mixing Gentle Mixing ensures no damage to mixed product Low Shear Low running and maintenance cost Guaranteed full load start Uniform Liquid Spray Pin-mill system to break lumps Spray bar with nozzles for liquid addition Jacket arrangements for heating and cooling CIP system for quick and efficient cleaning Applications The well engineered design and robust construction of Toshniwal Twin Shaft Paddle Mixers make it a very versatile mixing solution in different industries. A few to mention: Food Industry: Our Twin Shaft Paddle Mixers have been supplied for mixing Gulab Jamun Powder, Cereal Mix, Instant Coffee Powder, Food Additives, Dairy Feed Mix, Vending Premix, Hot Beverage Powder, Flavored tea mix, Muesli, Fortified Rice, Yeast Mix, Cake Premix, Electrolyte powder and many more Animal Feed Industry: Toshniwal Twin Shaft Paddle Mixers are widely used for manufacturing Feed Premix, Poultry Feed, Mineral Feed, Feed Supplements, Aqua feed mix, Feed Additives, Cattle Feed Mix, Vitamin Premix and Trace Elements Chemical Industry: Detergent Powder mixing, Fragrance stick powder, Fertilizer mixing, Pesticide Powder mixing, Foundry powder, Glass powder, Iron Ore powder, Micronutrient mixing, Soap powder mixing and many more. Refactory/ Building materials Industry: Distemper paint, Gypsum Plaster mix, Fly Ash mix, Abrasive powder, Cement Plaster mix, Ceramic material mix, Mortar mix and many more

batch mixer

Get Price Quote

Twin spiral ribbon type mixer with oil dozing arrangements to mix the ground powders homogeneously. Capacity of the mixer depends upon the output of the plant. The batch mixer has twin spiral mounted shaft rotating in a semi-circular enclosure with a pneumatically operated full length flap at bottom. We also supply Paddle type mixers

Nauta Mixer

Get Price Quote

Vertical Screw Blenders are excellent design alternatives for product applications that are shear sensitive, voluminous and also where space on the plant floor is at a minimum. Nauta mixers are widely used for mixing dry materials, paste, cream and lotions. The principle of blending is based on the differential travel speeds of product particles in the conical section of the vessel. The material from the bottom section of vessel is lifted by the screw and spread over the upper sections. Design Highlights The screw agitator turning on its axis produces a lifting action as it spirals the material in an upward flow At the same time the screw orbits the tank , the screw removes material away from wall and deflects it into the centre of the tank setting up a spiral current throught the batch The material lifted by the screw gravitates downwards thoroughly intermixing with material being spiralled upward. This results in most intimate intermingling of all ingredients When compared to horizontal blenders this design has several advantages The blending action of the slow turning screw is far gentler than that taking place within the horizontal blenders. Since the active blending volume at any given time is a lot lesser than the horizontal blenders, it results in a lower power requirement. The large handling capacity coupled with low power requirement makes it one of most effective and efficient Blender within the family.

paddle mixer machine

Get Price Quote

The Doris Double Paddle Mixer assists in mixing every particle into the other thus producing homogeneity. The Blades Scoop, lift and tumble materials in a gentle through mixing action. Blender can give excellent mixing even with small batches as low as 25%. It has short mixing time. Gently Mixing and Low Operating Cost with High Productivity. It has large discharge gate for quick discharge. The Mixer is available in Mild Steel and Stainless Steel in various capacities. It is designed for easy Cleaning and Quick batch changing. Every Paddle Mixer is backed up by service facilities offered by our Company

Sigma Mixer

Get Price Quote

Our Sigma mixers comprises of a container welded and machined together with the sigma blades. We have designed them keeping the clearances between the walls and the container to a minimum. This ensures maximum efficacy in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks. these are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakproof operations. The mixer is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. We also provide cooling and heating jackets. These types of machines are available in M.S. and S.S.contruction. The mixer can be tilted by means of a mechanical system or manually. For bigger models,we provide hydraulic tilting. Hydraulic tilting system comes with complete power pack, pressure valves, fittings, electric motor, cylinders, pipes and hoses which makes the tilting mechanism quick, easy and simple to operate. Capacity: We offer double Sigma Mixer in various capacities ranging from 10 to 500 liters. Applications: Varnishes & Paints Resins, Glues, Adhesives Polyurethanes Pharmaceuticals Inks Chemicals Food Lacquers Colourants Cosmetics

Sigma Mixer

Get Price Quote

Sigma mixer is a heavy duty mixer designed for dough mixing which is essential in the soaps, detergents, foods, rubber, chemical industries etc. The Z arm or Sigma blade is designed for uniform mixing and criss cross flow of materials. The blades rotate in the ratio of 1:1.5 ( 24 : 36 ) rpm The mixer is supplied with jacket or without jacket as per the requirement of the customer. We supply in different capacities with fully SS, Partly SS and fully MS constructions. Discharge is by hydraulic door opening system or through screw rod system. Heavy duty gear box and gears are used to withstand high viscous mixing. Sigma blades are solidly casted, machined, x ray tested before fitting. Minimal uniform gap is maintained between the trough and the blades.

Paddle Mixer

Get Price Quote

Sigma Mixers

Get Price Quote

Sigma Mixers, Agitated Nutsche Filter, vacuum, sparkler filters, sifters

Batch Mixers

Get Price Quote

Batch Mixers, Core Shooter Machine, Knuckle Joints, Pin Making Machine

SIGMA MIXER USM-300/600/900

Get Price Quote

SIGMA MIXER USM-300 / 600 / 900, sandel wood

Tumbler Mixers

Get Price Quote

Tumbler Mixers, Iodized Salt Plant

Sigma Mixer

Get Price Quote

Sigma Mixer, Double Cone Blender, Extruder Machine, Plastic Machinery

Tumbler Mixers

Get Price Quote

Tumbler Mixers

paste mixers

Get Price Quote

paste mixers, high speed dispersers, triple roll mills, Bead Mills