Benchtop Chamber

Get Price Quote

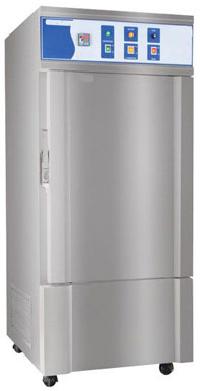

CME’s Benchtop Chamber is the smaller version of Climatic Test Chamber, which is so compact & calm that it can be placed on a bench or a roll out cart next to your workspace without causing any hindrance! CME’s Benchtop Chamber is the smaller version of Climatic Test Chamber, which is so compact & calm that it can be placed on a bench or a roll out cart next to your workspace without causing any hindrance! The Benchtop Chamber is ideal for conducting reliability testing on the specimen, which is smaller and light in weight. It is widely popular in the electronics and electrical industry where miniaturization is the norm of the industry and to test their reliability is crucial for a successful product launch. Being built with galvanised steel and epoxy based powder coating offers superior resistance to corrosion. Similar to its bigger sibling (climatic chamber) the test space is made of AISI-304 grade polished stainless steel with a load bearing capacity of 5 Kg- 10 Kg (UDL). The presence of the non-conducting silicon entry port (offer accessibility for electrical connection) helps to conduct real – time live testing. Equipped with a touch screen controller (Envicom Graphite Series) the benchtop chamber provides a unified testing experience like the climatic chamber but in a compact size. The chamber is available in 2 models namely the 25 litres and 80 litres with a temperature range of -60oC to 150oC & -30oC to 100 oC respectively. However, the Envicom Graphite series controller is equipped only with NC-25-B model whereas the NC-80-A has a single point Eurotherm controller. The humidity system is optional but if needed, it provides the humidity range between 20%RH to 95%RH. The benchtop chamber also comes with a wide range of optional accessories such as the GPIB converter, graphical data logging software, 6-channel data logger, etc. to enhance your testing process. The chamber has been designed and validated by a team of international engineers and technicians, and special attention to detail has been given to its internal systems. An in-built air-cooled condenser has been used for high cooling efficiency with the lowest noise. The cascade refrigeration system designed for the chamber offers the highest reliability with minimum power consumption. Its cooling intelligence technology gauges the demand for cooling and automatically switches off the compressor during soak and ramp up mode, saving a significant amount of power. The built in safety feature systems such as the hot gas bypass system, liquid bypass system, overload protection, etc. all. It constantly monitors the operations of the chamber and sends out alert messages during malfunction.