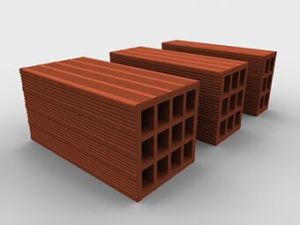

Wire Cut Bricks

Get Price Quote

We bring forth excellent quality Wire Cut Bricks that are highly acclaimed among the customs. The unmatched quality and effective performance of the Orange Wire Cut Bricks have attracted various clients to place bulk orders. The use of optimum quality materials in the manufacturing of the Plain Wire Cut Bricks ensures their high durability and resistivity to adverse conditions. Additionally, you can avail Wire Cut Bricks in various sizes and dimensions as per the specifications provided.

Red Clay Bricks

9 - 11 Per Nos

5000 n (MOQ)

Best Deals from Building Brick

building brick

Get Price Quote

Buyers can place bulk or retail orders with us all year round and expect on time delivery of consignments. Founded in Chennai(India), our company has been successful in capturing the local and domestic markets as trader of this product

Wire-cut Brick

Get Price Quote

Machine processed Wire-cut brick of very good strength. SKU BR034

Wire Cut Bricks

Get Price Quote

Details A brick cut from clay shaped by extrusion before burning; the long bar of extruded clay is cut into bricks by a set of wires 9 inches (23 centimeters) apart. PRODUCT SUMMARY Wire cut bricks low cement consumption during brick work and plastering is not at all required, Wire cut bricks are made by extruding or forcing clay to form a long column, which is then wire cut into evenly

Fly Ash Bricks

8 - 8 Per Nos

Red Bricks

250 Per Square Feet

50 Square Feet (MOQ)

Fly Ash Brick

Get Price Quote

Fly Ash Bricks

Get Price Quote

Fly Ash Bricks 4"

43 - 45 Per piece

2750 piece (MOQ)

Fly Ash Brick

Get Price Quote

flyash bricks

Get Price Quote

Fly Ash Brick is a product of basic cement clinker materials i.e. FLY ASH, STONE DUST SAND, LIME, GYPSUM and BONDING AGENT. The mix is so ideally worked out to produce bricks of higher strength, with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology.At Literoof we take utmost care in curing our products.Our products go through specialised curing process called chamber curing where hot air is circulated until the products reach the desired strength. Though a new age product introduced in the market, Fly Ash Bricks are very well accepted by the organized sectors in heavy industries, high rise buildings, large townships, colonies, etc. because of unique features and merits. Advantages of using SHIEELD brand fly ash bricks Environmental Friendly Green building concept Used in face work due to uniformity and smoothness Less usage of mortar & saving in manpower Direct gypsum plaster can be done Dimensional accuracy Less penetration of water in brick work Light weight Fire resistance and sound insulation Less usage of water NORMAL CLAY BRICK FLY ASH BRICK Varying colour as per soil Uniform pleasing colour like cement Uneven shape as hand made Uniform in shape and smooth in finish Lightly bonded Dense composition Plastering required No plastering required Heavier in weight Lighter in weight Compressive strength is around 35 Kg/cm2 Compressive strength is around 100 Kg/cm2 More porous Less porous Thermal conductivity 1.25 – 1.35 W/m2 ºC Thermal conductivity 0.90-1.05 W/m2 ºC Water absorption 20-25% Water absorption 6-12%

Wire Cut Bricks

Get Price Quote

exposed wire cut bricks

Get Price Quote

Available in different sizes, our Exposed Wire Cut Bricks are widely used for exposed masonry and making the roof 100% waterproof. We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. Owing to our well-established set-up in Chennai(India), we are capable of catering to the requirements of clients with utter ease.

Wire Cut Bricks

Get Price Quote

WIRE CUT BRICKS The use of optimum quality materials in the manufacturing of the Plain Wire Cut Bricks are of optimum quality that ensures notable features like high durability and resist nature to adverse conditions. Available sizes 9 X 4-5 /16 X 3 ( in inches ) Brick Usage - There are three main categories of use, and both pressed bricks or wire-cut brick types are used in all three categories. Facing brickwork - is the visible decorative work. Engineering brickwork - often seen in bridges and large industrial construction but may also be hidden in ground works where maximum durability is required, e.g., in manhole construction. Common brickwork - is not usually seen and is used where engineering qualities are not required; below ground in domestic buildings and internal walls, for instance. Wire-cut - bricks may be laid either way up but some types of wire cuts have a textured (combed) face, creating folds in the face of the brick, which is directional. It is advisable to lay these bricks with the folds hanging downward to maximize the weathering characteristics of the brick. Wire cut bricks are made by extruding or forcing clay to form a long column, which is then wire cut into evenly shaped rectangular bricks. Better Insulation. More Strength. Sharp and even edges ensure saving in mortar costs. Faster Installation - Saving time and labor. Better Endurance against elements of nature - Rain Sunshine and Wind.

Red Bricks

Get Price Quote

Specification: We produce one of the best quality of baked bricks going through all the standards as required. Bricks can also be produced with clients logo emarked on it.

Red Bricks

Get Price Quote

Being a quality-oriented organization, we are focused to provide our clients excellent quality BRICKS. Offered bricks are carefully processed with the utilization of standard quality basic material. These bricks are made to pass through rigorous tests on the counts of quality, resistivity towards adverse conditions and finish.

Wire Cut Bricks

0 Per Piece

10000 Piece(s) (MOQ)

We are manufacturer and exporter of high quality wire cut bricks. widely deliver our products in world wide at low price and high quality. low cement consumption during brick work and plastering is not at all required, compressive strength - 100kg/cm2 advantages:- high compressive strength, low water absorption, resistant to earth quake, several load bearing grades, savings in mortar plastering, better insulation. light weight. sharp and even edges ensure saving in mortar costs. faster installation - saving time and labour. better endurance against elements of nature - rain sunshine and wind. eliminates damage during transportation & breakage, smart look brick work during construction,

hot face insulation brick

Get Price Quote

clay hollow bricks

Get Price Quote

Advantages Light weight - up to 60% less weight than conventional walling material. Excellent thermal insulation. High compressive strength. Natural and green product. Faster construction and ease of handling.

industrial fly ash brick

Get Price Quote

We are a prominent name in this domain, providing superior quality assortment of Industrial Fly Ash Brick. Our product range is tested for quality under various set norms of the industry. Moreover, this Industrial Fly Ash Brick is widely demanded for its features like easy to install, high quality and easy to maintain. Features: Longer service life Easy maintenance Quality tested

Building AAC Brick

Get Price Quote

Red Bricks

11 Per Piece

3000 Piece (MOQ)

Construction Bricks

Get Price Quote

As a respectable firm, we import, export and supply the best Construction Bricks. These Construction Bricks are widely used in the Construction industry. We can easily handle the bulk orders of Construction Bricks as per the requirement of the clients. Moreover, we offer these Construction Bricks at the market leading prices. Minimum Order Quantity : 1 ton

Fly Ash Bricks

9 Per Piece

1000 Piece (MOQ)

Fly Ash Brick

Get Price Quote

Jebajeyam Bricks manufacturers Fly ash bricks with the automated technology and machinery. Fly ash bricks replace the bricks in many aspects and on the cost-effectiveness. Fly ash bricks sell cheaper than the bricks but offers a big gain in overall construction cost. FAB is a novel phenomenon in the construction market. Timely delivery of the bricks is assured to the clients. We have been excelling in the market of FAB in the recent times. There are several things contributed to the success of us; timely delivery, novelty, reliability and hard work. Our bricks are widely used in several construction purposes in the real estate fraternity in Chennai. We have successfully won the confidence of many reputed real estate giants in the city, which are our regular customers.

Fly Ash Brick

5 Per Piece

Direct factory sale size 230 x 110 x 75 mm strength m9 grade water absorbsion 10% fly ash brick its a cost saving building material that also reduces requirement of cement for mortar and plastering. Unlike clay bricks it has its perfect shape results accuracy in masonry work. Keeps your building cool, (due to high silica content of fly ash). Highly qualified for load bearing walls and foundation walls. Less water absorption. Higher compression strength. Heat resistance. Highly eco-friendly unlike the conventional clay bricks, fly ash bricks have higher affinity to cement mortar and plaster; due to the crystal growth between fly ash in the brick and cement the joints will become stronger and in due course of time it will become monolithic. 1)no green house gas emission on production. 2)no top soil dug out from earth surface. 3)fly ash emmited from thermal power stations utilized vastly.

Red Bricks

Get Price Quote

This transformation comes with the strong belief that the fest will set the stage for a business ecosystem comprising the strengths of the three independent events while leveraging on the synergies that such a union would bring about.The fest is to be held from September 29 to October 2 and will witness stalwarts from the business world coming together at the campus amidst an expected footfall of over 20,000, to give their insights on the various facets of the business world.

Wire Cut Bricks

7 Per Piece

Hot Face Kyanite Brick

Get Price Quote

1000 Piece(s) (MOQ)